Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Numerical Tool Programmer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Numerical Tool Programmer so you can tailor your answers to impress potential employers.

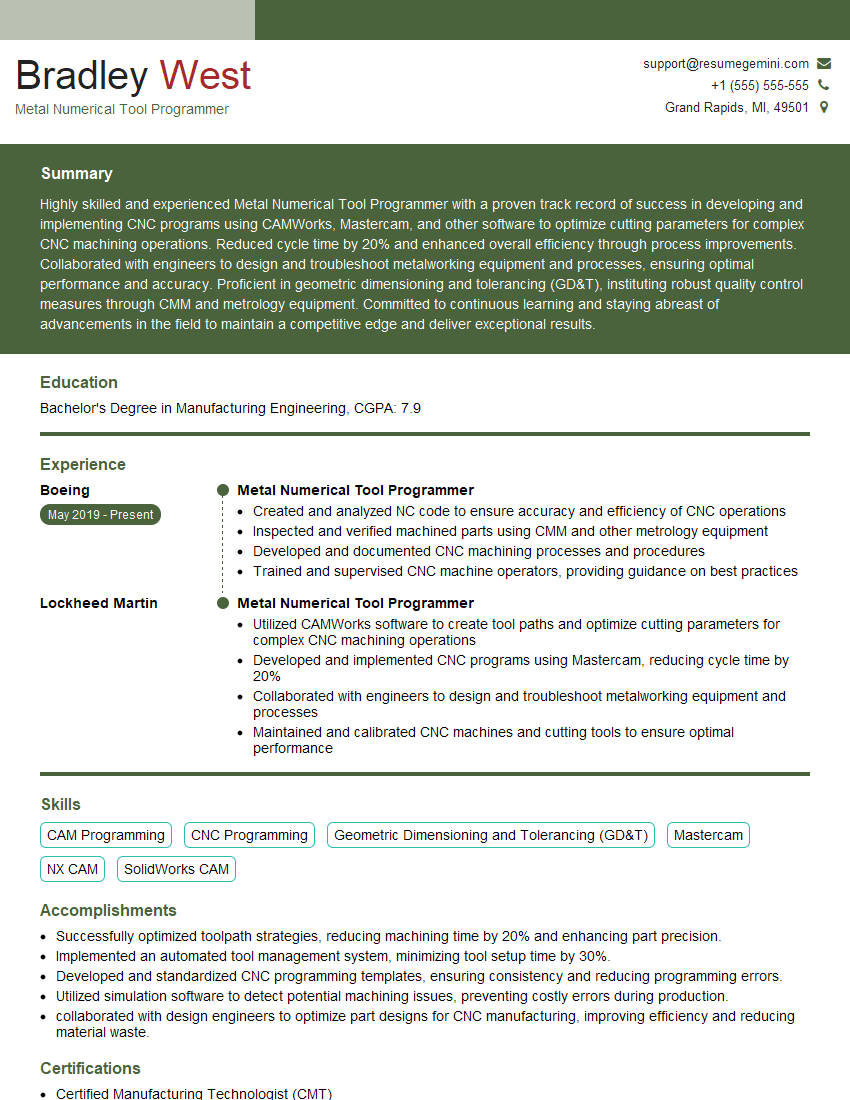

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Numerical Tool Programmer

1. What is your experience with different CNC machine systems such as Fanuc, Siemens, and Heidenhain?

- I have extensive experience with Fanuc, Siemens, and Heidenhain CNC machine systems.

- I am proficient in programming, setting up, and operating these systems to produce high-quality parts.

2. Can you explain the process of creating a CNC program from a CAD model?

of the answer

- The process of creating a CNC program from a CAD model involves several steps:

- Importing the CAD model into the CAM software.

Subheading of the answer

- Creating the toolpaths for the cutting operations.

- Simulating the program to verify that it will produce the desired part.

3. What types of cutting tools are used in CNC metalworking and how do you select the appropriate tool for a specific job?

- There are a wide variety of cutting tools used in CNC metalworking, each designed for a specific purpose.

- The type of tool selected for a job depends on the material being cut, the desired surface finish, and the geometry of the part.

4. How do you ensure the accuracy and precision of CNC-machined parts?

- Ensuring the accuracy and precision of CNC-machined parts involves several key steps:

- Properly calibrating and maintaining the CNC machine.

5. What are the common challenges faced in metal numerical tool programming and how do you overcome them?

- Some common challenges faced in metal numerical tool programming include:

- Complex part geometries.

6. How do you keep up with the latest advancements in CNC technology and programming techniques?

- To keep up with the latest advancements in CNC technology and programming techniques, I:

- Attend industry conferences and workshops.

7. Can you describe your experience with using CAD/CAM software for CNC programming?

- I have extensive experience with using CAD/CAM software for CNC programming, including:

- Mastercam.

8. What is your approach to troubleshooting CNC programming errors?

- My approach to troubleshooting CNC programming errors involves:

- Identifying the source of the error.

9. How do you optimize CNC programs for efficiency and accuracy?

- To optimize CNC programs for efficiency and accuracy, I:

- Use efficient toolpaths.

10. Can you provide an example of a complex CNC program that you have written and the challenges you faced in developing it?

- One example of a complex CNC program that I have written is a program for machining a complex aerospace component.

- The challenges I faced in developing this program included the complex geometry of the part and the need to achieve high accuracy and precision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Numerical Tool Programmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Numerical Tool Programmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Numerical Tool Programmers utilize their knowledge of Computer-Aided Manufacturing (CAM) software to create numerical control (NC) programs that direct the operations of computer-controlled machine tools. These programs specify the precise movements and actions of the machine tools, ensuring the accurate and efficient production of metal parts and components.

1. NC Program Development

Hold a thorough understanding of NC programming languages, including G-code and M-code, to create NC programs that govern the movements and actions of CNC machines.

- Interpret engineering drawings and specifications to determine the required geometry, dimensions, and tolerances of the metal parts.

- Select the appropriate cutting tools, feeds, and speeds based on the material being processed and the desired surface finish.

2. Machine Tool Operation and Maintenance

Exhibit proficiency in the setup, operation, and maintenance of CNC machines. Ensure that the machines are properly calibrated and operating optimally.

- Mount and secure the metal workpiece on the machine table, ensuring proper alignment and stability.

- Execute the NC programs and monitor the machining process, making necessary adjustments to optimize performance.

3. Quality Control and Inspection

As part of their responsibilities, they are expected to perform quality control checks on the finished metal parts to ensure they meet the specified requirements.

- Measure and inspect the parts using precision measuring instruments to verify their dimensions, tolerances, and surface finish.

- Identify and rectify any deviations from the specifications, making adjustments to the NC programs or machine settings as needed.

4. Continuous Improvement

Strive for continuous improvement by exploring ways to enhance the efficiency and accuracy of the NC programming and machining processes.

- Stay abreast of the latest advancements in CAM software, NC programming techniques, and CNC machine capabilities.

- Proactively seek opportunities to streamline workflows, reduce cycle times, and improve the overall productivity of the manufacturing process.

Interview Tips

Preparing for an interview for a Metal Numerical Tool Programmer position requires a combination of technical knowledge and presentation skills. Here are some tips to help you make a positive impression and showcase your qualifications.

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, products, and services. Research the specific job requirements and responsibilities to demonstrate your understanding of the role.

- Visit the company’s website, LinkedIn page, and any recent news articles to gain insights into their operations and culture.

- Carefully review the job description and identify the key skills and experiences required for success in the position.

2. Highlight Your Technical Skills

Emphasize your proficiency in CAM software, NC programming, and CNC machine operation. Provide examples of complex NC programs you have developed and successfully implemented.

- Quantify your accomplishments by providing specific metrics, such as increased production efficiency or reduced cycle times.

- Be prepared to discuss your understanding of G-code and M-code, as well as your experience with different CNC machine types.

3. Showcase Your Problem-Solving Abilities

Demonstrate your ability to troubleshoot and resolve technical issues related to NC programming and CNC machine operation.

- Share real-life examples where you identified and solved problems that impacted production efficiency or part quality.

- Highlight your analytical skills and your systematic approach to problem-solving, emphasizing your ability to identify root causes and implement effective solutions.

4. Prepare for Common Interview Questions

Anticipate common interview questions related to your technical skills, such as:

- “Describe your experience with developing and implementing NC programs.”

- “How do you ensure the accuracy and efficiency of your NC programs?”

- “Discuss your knowledge of CNC machine operation and maintenance.”

Prepare thoughtful and concise answers that showcase your expertise and enthusiasm for the field.

5. Practice Your Presentation Skills

Practice your answers out loud to improve your delivery and articulation. Use clear and concise language, and be confident in presenting your qualifications.

- Consider recording yourself and reviewing your responses to identify areas for improvement in terms of clarity, pacing, and tone.

- Seek feedback from a friend, family member, or career counselor to gain an outsider’s perspective on your presentation skills.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Metal Numerical Tool Programmer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Metal Numerical Tool Programmer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.