Are you gearing up for an interview for a Metal Organ Pipe Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Organ Pipe Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

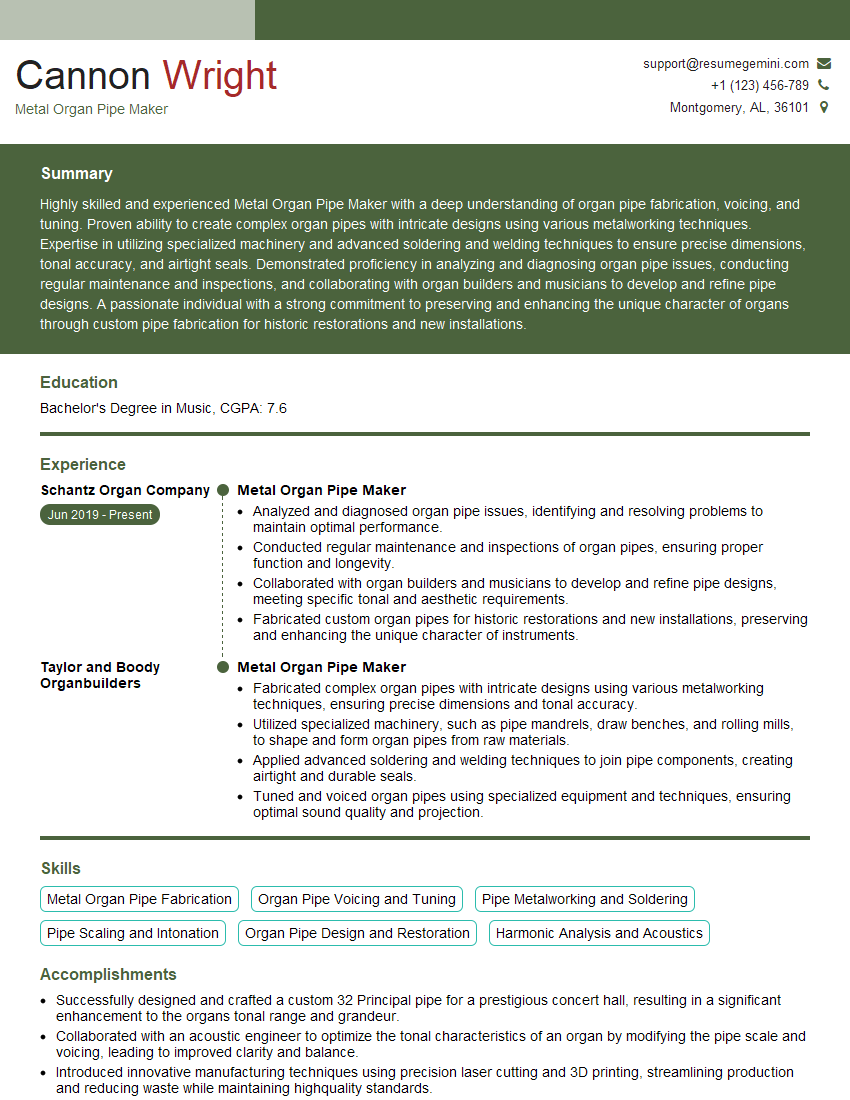

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Organ Pipe Maker

1. What are the primary materials used in making metal organ pipes?

- Zin

- Lead

- Zinc-lead alloy

- Tin

2. Describe the process of making a metal organ pipe, from start to finish.

Shape and Scale

- Create metal sheets to the desired shape and scale of the pipe

- Roll the sheet into a cylindrical or conical shape

Brazing and Soldering

- Join the seam of the pipe using brazing or soldering

- Ensure the joint is airtight and durable

Voicing

- Adjust the shape, length, and other parameters of the pipe

- Alter the sound produced by the pipe

Finishing

- Polish or apply a finish to the pipe

- Provide protection and enhance the appearance

3. What are the different types of organ pipes and their purpose?

- Flute pipes: Produce a pure, clear sound resembling the human voice

- Reed pipes: Create a vibrant, rich sound using a vibrating reed

- Diapason pipes: Foundation pipes providing a clear, loud sound

- Principal pipes: Brighter, more prominent sound than diapason pipes

4. What tools and equipment are essential for a metal organ pipe maker?

- Metalworking tools (hammers, pliers, shears)

- Soldering equipment (soldering iron, solder)

- Measuring and marking tools (ruler, calipers)

- Voicing tools (files, scrapers)

- Specialized tools for organ pipe making (pipe bender, cone former)

5. How do you ensure the intonation and pitch of an organ pipe?

- Intonation: Adjust the length and shape of the pipe using voicing tools

- Pitch: Alter the length of the pipe to match the desired note

- Use tuning equipment (tuner, microphone) to measure and adjust accurately

6. What materials are suitable for use in the construction of organ pipes?

- Metals: Tin, lead, zinc, zinc-lead alloy

- Wood: Used for resonators and wind chests

- Other materials: Leather, felt, plastic (for certain components)

7. How do you maintain the quality and performance of metal organ pipes?

- Regular cleaning: Remove dust and debris using a soft brush or cloth

- Periodic tuning: Adjust intonation and pitch to maintain accurate sound

- Environmental control: Ensure proper humidity and temperature levels

- Repairs: Address any damage or wear-and-tear promptly

8. What are the common problems encountered when making metal organ pipes and how do you address them?

- Air leaks: Seal any gaps or holes with solder or glue

- Incorrect intonation: Adjust the length and shape of the pipe using voicing tools

- Corrosion: Protect the pipe with appropriate finishes or coatings

- Mechanical issues: Repair or replace any damaged components

9. How do you stay up-to-date with the latest advancements and techniques in metal organ pipe making?

- Attend industry conferences and workshops

- Study technical journals and publications

- Connect with other organ builders and craftsmen

- Explore online resources and forums

10. How do you approach the restoration or repair of a vintage metal organ pipe?

- Assessment: Examine the pipe’s condition and identify any issues

- Restoration: Repair or replace damaged components, maintain original materials and techniques

- Intonation and tuning: Adjust the pipe to its original sound and pitch

- Finish: Apply appropriate finishes to protect and enhance the appearance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Organ Pipe Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Organ Pipe Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Organ Pipe Makers are highly skilled artisans responsible for crafting metal pipes for pipe organs. Their work requires precision, attention to detail, and a deep understanding of the principles of sound production.

1. Pipe Construction and Assembly

Metal Organ Pipe Makers construct metal pipes from various materials such as zinc, copper, and lead. They shape and solder the metal sheets to create the pipe’s body, mouth, and toe. Additionally, they assemble and fit internal components, such as the reed and languid, to ensure proper sound production.

2. Pipe Tuning and Voicing

Once the pipes are constructed, Metal Organ Pipe Makers tune and voice them to achieve the desired pitch and tonal quality. This involves adjusting the pipe’s length, shape, and other parameters to match the specific requirements of the organ. They use specialized tools and techniques to shave or add metal, altering the pipe’s dimensions.

3. Quality Control and Inspection

Metal Organ Pipe Makers are responsible for ensuring the quality of their work. They inspect each pipe for any defects or inconsistencies. They verify the accuracy of the pipe’s dimensions, sound production, and overall craftsmanship.

4. Research and Development

Metal Organ Pipe Makers may also participate in research and development to improve the design and construction of metal pipes. They experiment with new materials, techniques, and technologies to enhance the sound quality and durability of the pipes.

Interview Tips

To ace an interview for a Metal Organ Pipe Maker position, it is crucial to prepare thoroughly and demonstrate your skills and knowledge.

1. Research the Company and Position

Before the interview, take the time to research the organ building company and the specific position you are applying for. This will help you understand the company’s values, products, and culture. It will also provide you with insights into the specific requirements of the role.

2. Showcase Your Skills and Experience

Highlight your abilities in metalworking, pipe construction, and tuning and voicing. Provide specific examples of your past projects and the techniques you used. Quantify your accomplishments whenever possible to demonstrate your impact.

3. Discuss Your Understanding of Organ Construction

Demonstrate your knowledge of the principles of sound production and the different types of organ pipes. Explain how you approach the construction and tuning of pipes to achieve the desired tonal quality.

4. Prepare for Questions on Quality Control

Be prepared to discuss your quality control procedures and how you ensure the accuracy and consistency of your work. Emphasize your attention to detail and your commitment to delivering high-quality products.

5. Express Your Passion and Enthusiasm

Convey your passion for organ pipe making and your commitment to the craft. Explain why you are drawn to this specialized field and what motivates you to pursue it.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Organ Pipe Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.