Are you gearing up for an interview for a Metal Pickling Equipment Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Pickling Equipment Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

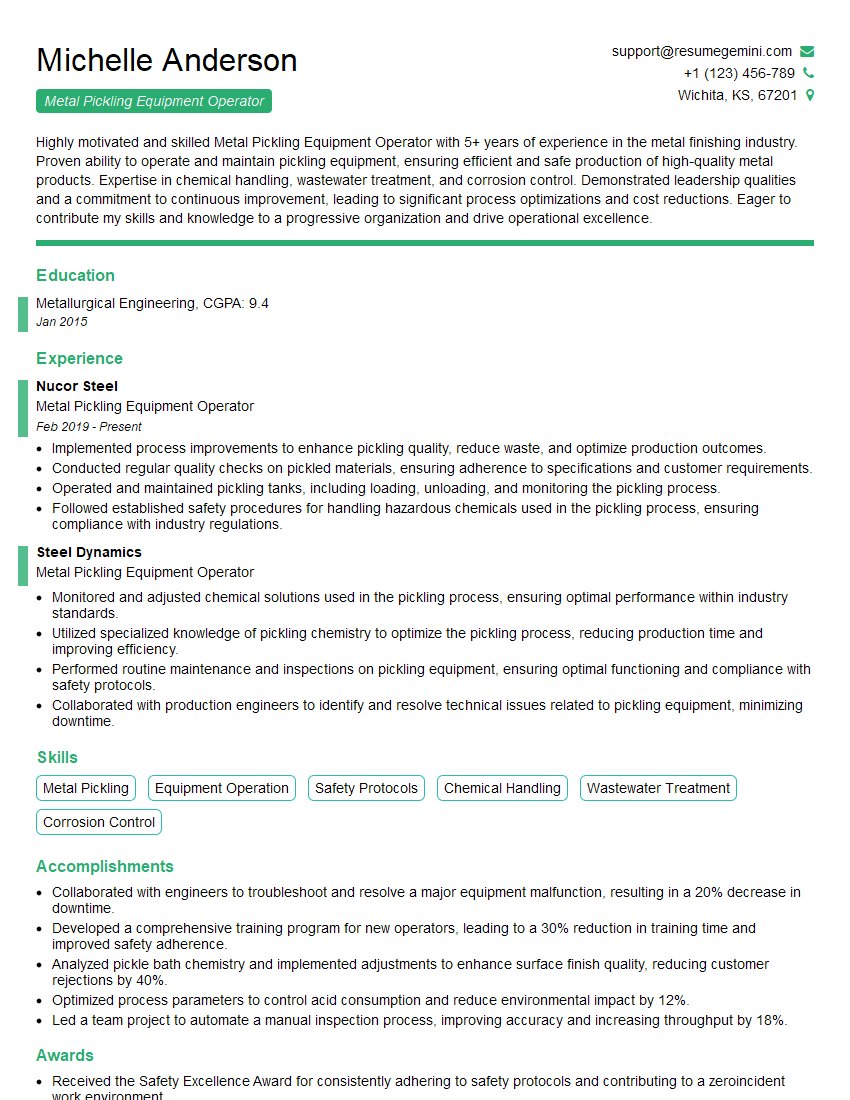

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Pickling Equipment Operator

1. Describe the key responsibilities of a Metal Pickling Equipment Operator?

- Operate and monitor metal pickling equipment to remove rust, scale, and other contaminants from metal surfaces.

- Control the concentration of acid and other chemicals used in the pickling process.

- Inspect pickled metal to ensure it meets quality standards.

- Maintain and repair pickling equipment.

- Follow safety protocols and regulations related to the handling and disposal of hazardous materials.

2. Explain the different types of metal pickling processes?

Acid Pickling

- Uses hydrochloric acid or sulfuric acid to dissolve oxides and scale.

- Suitable for removing rust, heat scale, and mill scale.

Alkali Pickling

- Uses sodium hydroxide or potassium hydroxide to remove oxides and oils.

- Suitable for removing light rust and polishing the metal surface.

Electrolytic Pickling

- Uses an electric current to remove oxides and scale.

- Provides high-quality surface finish and is suitable for complex shapes.

3. What are the safety precautions that must be taken when operating metal pickling equipment?

- Wear appropriate personal protective equipment, including gloves, goggles, and a respirator.

- Handle acid and other chemicals with care, following proper handling and disposal procedures.

- Ensure adequate ventilation in the work area to prevent exposure to fumes.

- Be aware of the potential for explosions and fires.

- Follow all safety protocols and regulations established by the company and regulatory agencies.

4. How do you determine the appropriate concentration of acid or alkali for the pickling process?

- Refer to manufacturer’s recommendations and industry standards.

- Consider the type of metal being pickled and the desired surface finish.

- Use titration or pH testing to measure the concentration of the pickling solution.

- Monitor the solution regularly and adjust the concentration as needed.

5. Describe the steps involved in maintaining and repairing metal pickling equipment?

- Inspect equipment regularly for wear and tear.

- Clean and lubricate moving parts as per manufacturer’s instructions.

- Replace worn or damaged parts promptly.

- Calibrate sensors and instruments to ensure accuracy.

- Follow proper maintenance schedules and keep records of all maintenance activities.

6. How do you troubleshoot common problems that occur with metal pickling equipment?

- Identify the problem and its potential causes.

- Check for leaks, clogs, or electrical faults.

- Adjust settings, replace parts, or perform repairs as necessary.

- Consult with the equipment manufacturer or a qualified technician for more complex issues.

- Document the troubleshooting process and the resolution for future reference.

7. What are the different types of metal surfaces that can be pickled?

- Steel

- Stainless steel

- Aluminum

- Copper

- Brass

8. What is the purpose of using inhibitors in the pickling process?

- Reduce the rate of acid attack on the metal surface.

- Prevent over-pickling and ensure a uniform finish.

- Minimize hydrogen embrittlement and other adverse effects on the metal.

9. How do you ensure the quality of the pickled metal?

- Inspect the metal surface for any defects, such as pitting or etching.

- Measure the thickness of the pickled layer.

- Perform hardness testing to ensure the metal meets the required specifications.

- Follow established quality control procedures and maintain records of all inspections.

10. Describe your experience in working with metal pickling equipment?

- Provide specific examples of your responsibilities and accomplishments.

- Highlight your knowledge of different metal pickling processes and equipment.

- Discuss any safety or quality initiatives you implemented to improve the pickling operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Pickling Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Pickling Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Pickling Equipment Operators perform a crucial role in metal production lines, handling the equipment and processes involved in cleaning and preparing metal surfaces for further operations. Their key responsibilities include:

1. Equipment Operation and Maintenance

Masterfully operate metal pickling equipment, including acid tanks, rinsing stations, and drying ovens, to efficiently clean and process metal surfaces.

- Monitor and adjust equipment parameters, such as temperature, chemical concentrations, and agitation speed, to ensure optimal performance.

- Regularly maintain and troubleshoot equipment to prevent breakdowns and ensure smooth production.

2. Material Handling

Safely load and unload metal workpieces onto the pickling line, ensuring they are properly positioned and secured.

- Follow established safety protocols while handling and moving heavy metal components.

- Inspect workpieces for surface defects and contamination before and after processing.

3. Quality Control

Monitor and inspect pickled metal surfaces to ensure they meet the required quality standards.

- Conduct visual inspections and use testing equipment to verify the cleanliness, smoothness, and corrosion resistance of the surfaces.

- Identify and resolve any quality issues, ensuring that processed metal meets specifications.

4. Production Optimization

Collaborate with production and maintenance teams to optimize pickling processes and increase efficiency.

- Analyze production data to identify areas for improvement and reduce processing times.

- Implement best practices and troubleshoot issues to minimize downtime and maximize equipment utilization.

Interview Tips

To ace your interview for a Metal Pickling Equipment Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s operations, the metal pickling industry, and recent trends in metal surface treatment.

- Visit the company website to learn about their products, services, and values.

- Read industry publications and attend webinars to stay up-to-date on best practices.

2. Emphasize Your Technical Skills and Experience

Highlight your proficiency in operating metal pickling equipment and your understanding of the underlying chemical processes.

- Describe specific examples of how you have successfully operated and maintained pickling equipment.

- Explain your knowledge of acid chemistry, metal surface properties, and quality control techniques.

3. Showcase Your Safety and Quality Consciousness

Emphasize your commitment to safety and your focus on producing high-quality pickled metal.

- Describe your experience with following safety protocols in a manufacturing environment.

- Explain how you ensure that pickled metal surfaces meet the required specifications.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and qualifications.

- Explain your understanding of the metal pickling process.

- Describe your experience with troubleshooting and resolving equipment issues.

- How do you prioritize safety and quality in your work?

- What are your goals for professional development in this role?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Pickling Equipment Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!