Are you gearing up for a career in Metal Polisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Polisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

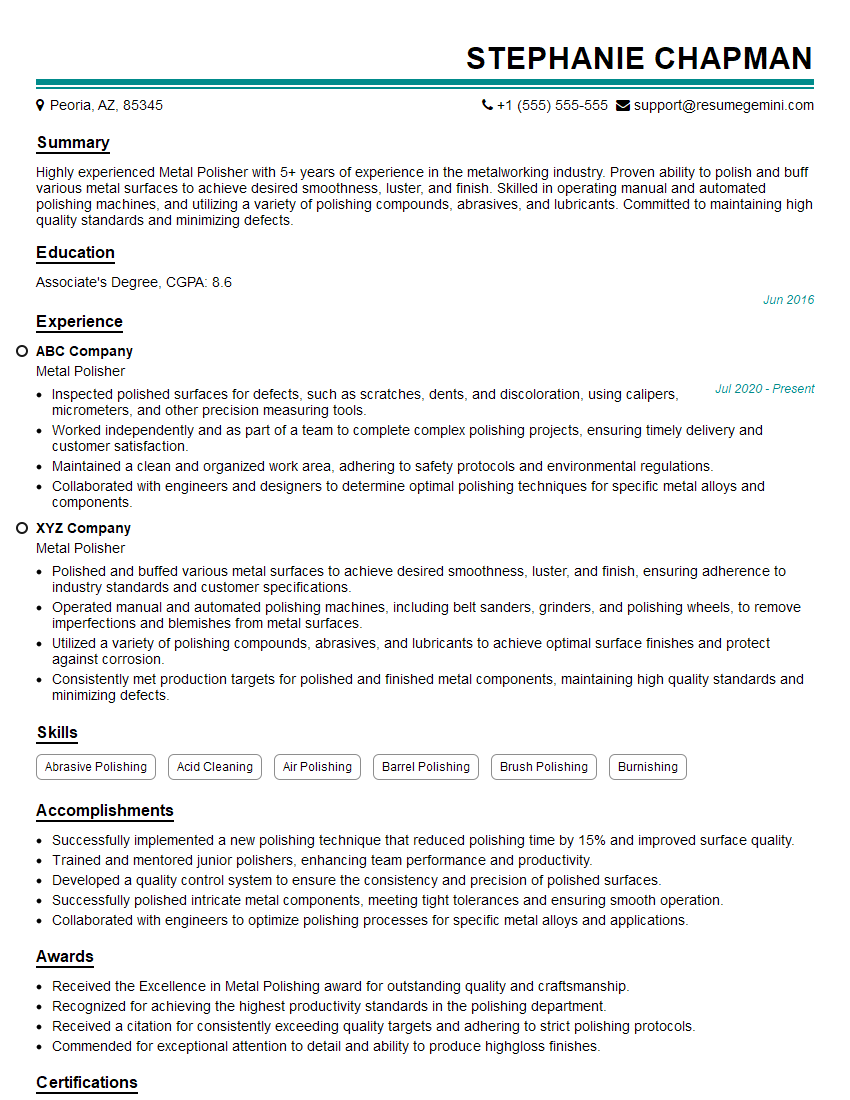

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Polisher

1. What are the different types of polishing wheels and when do you use each type?

- Buffing Wheel: Made of soft materials like cotton or flannel, used for final finishing work to achieve a high gloss.

- Polishing Wheel: Made of denser materials like sisal or canvas, used for cutting and removing scratches.

- Tripoli Wheel: Impregnated with tripoli compound, used for removing heavy scratches.

- Emery Wheel: Coated with abrasive grit, used for grinding and shaping metal.

2. What safety precautions should you take when using polishing machinery?

Eye Protection

- Wear safety glasses or goggles to protect your eyes from flying debris.

Hearing Protection

- Use earplugs or muffs to minimize noise exposure.

Gloves

- Wear gloves to protect your hands from abrasives and chemicals.

3. How do you determine the correct polishing compound for a particular metal?

- Consider the hardness of the metal.

- Review the manufacturer’s recommendations.

- Test different compounds on a small area to determine which one works best.

4. What techniques do you use to achieve a mirror finish?

- Start with a coarse abrasive.

- Gradually move to finer abrasives.

- Use overlapping strokes.

- Maintain consistent pressure.

5. How do you inspect polished surfaces for defects?

- Use a magnifying glass or microscope.

- Check for scratches, pits, or other imperfections.

- Inspect the surface under different lighting conditions.

6. What are the common causes of polishing problems and how do you troubleshoot them?

- Chattering:** Caused by uneven pressure or improper wheel alignment; adjust pressure or reposition the wheel.

- Burning:** Caused by excessive heat; reduce pressure or use a less aggressive compound.

- Smearing:** Caused by using a dirty wheel or compound; clean the wheel or change the compound.

7. What are the different methods of polishing metals?

- Mechanical Polishing: Using rotating wheels or brushes with abrasive compounds.

- Chemical Polishing: Using chemical solutions to remove material.

- Electrolytic Polishing: Using an electric current to smooth the surface.

8. How do you handle delicate or intricate metal pieces during polishing?

- Use soft polishing wheels and light pressure.

- Support the piece with a mandrel or backing plate.

- Be patient and take your time.

9. What is the difference between wet and dry polishing?

- Wet Polishing: Using water or other lubricants to reduce friction and heat.

- Dry Polishing: Polishing without lubricants, resulting in a hotter and faster process.

10. How do you stay updated on the latest polishing techniques and technologies?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Experiment with different methods and products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Polishers are responsible for restoring the luster and shine of metal surfaces. They use a variety of tools and techniques to remove scratches, dents, and other imperfections from metal objects. Some of their key responsibilities include:

1. Preparing metal surfaces for polishing

This involves cleaning the surface to remove any dirt or debris, and then applying a polishing compound to help protect the surface.

2. Polishing metal surfaces

This involves using a variety of tools, such as buffers, wheels, and abrasives, to remove scratches, dents, and other imperfections from the surface.

3. Buffing metal surfaces

This involves using a soft cloth or wheel to bring out the shine of the metal surface.

4. Cleaning and maintaining polishing equipment

This involves cleaning and maintaining the tools and equipment used to polish metal surfaces.

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to make the process easier and increase your chances of success. Here are a few tips to help you ace your next metal polisher interview:

1. Research the company and the position

Take some time to learn about the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture, their goals, and what they’re looking for in a metal polisher.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This will show the interviewer that you’re serious about the position and that you respect their time.

4. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a metal polisher. Be prepared to talk about your past experience, your skills, and how you can contribute to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Polisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.