Feeling lost in a sea of interview questions? Landed that dream interview for Metal Roofing Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Roofing Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

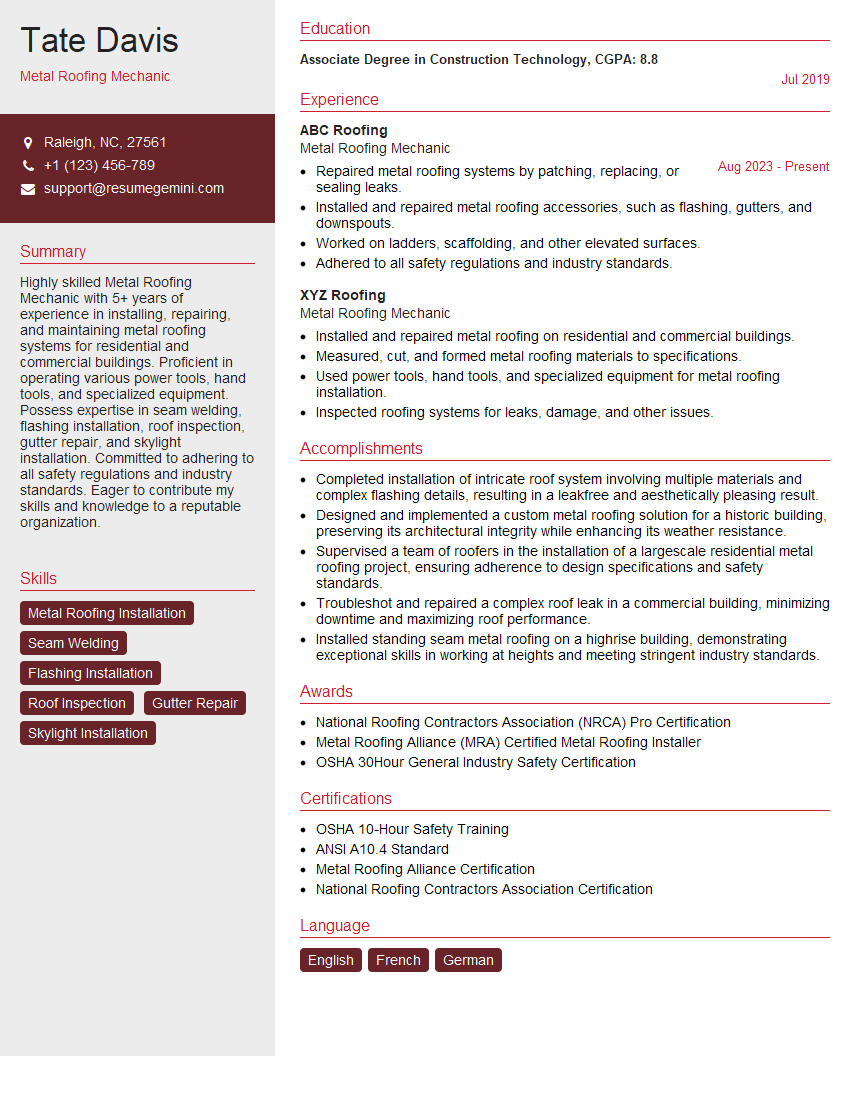

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Roofing Mechanic

1. What are the different types of metal roofing systems and their advantages?

There are several types of metal roofing systems, each with its own unique advantages:

- Standing seam panels: These panels are interlocked together at the seams, creating a weathertight seal. They are known for their durability and longevity.

- Exposed fastener panels: These panels are attached directly to the roof deck, providing a more economical option. They are still durable and weather-resistant, but may require more maintenance than standing seam panels.

- Metal tiles: These panels resemble traditional clay or slate tiles, but are made from metal. They offer a high degree of style and sophistication, and are also highly durable.

- Metal shingles: These panels are designed to look like asphalt shingles, but offer the benefits of metal roofing. They are lightweight, durable, and fire-resistant.

2. How do you calculate the amount of metal roofing material needed for a job?

Calculating the roof area:

- Measure the length and width of each roof section.

- Multiply the length and width to find the area of each section.

- Add the areas of all sections to find the total roof area.

Calculating the material quantity:

- Determine the coverage area of the metal roofing panels you will be using.

- Divide the total roof area by the coverage area of the panels.

- Add 10-20% for waste and overlap.

3. What are the common problems associated with metal roofing and how do you address them?

Some common problems associated with metal roofing include:

- Condensation: Metal roofs can condense moisture on the underside, especially in cold climates. This can be addressed by installing a vapor barrier and proper insulation.

- Corrosion: Metal roofs can be susceptible to corrosion, particularly in coastal areas. This can be addressed by using corrosion-resistant metals such as aluminum or zinc-coated steel.

- Noise: Metal roofs can be noisy during heavy rain or wind. This can be addressed by installing sound-dampening materials.

- Dents and scratches: Metal roofs can be dented or scratched during installation or use. These can be repaired using touch-up paint or by replacing the damaged panels.

4. What are the safety precautions that should be taken when working on metal roofing?

When working on metal roofing, it is important to take the following safety precautions:

- Wear proper safety gear: This includes a hard hat, safety glasses, gloves, and appropriate footwear.

- Use caution when walking on metal roofs: Metal roofs can be slippery, especially when wet or icy.

- Be aware of sharp edges: Metal roofs can have sharp edges that can cut or puncture skin.

- Avoid working on metal roofs during inclement weather: Wind, rain, and snow can make working on metal roofs dangerous.

5. What are the different types of tools and equipment used in metal roofing installation?

The following tools and equipment are commonly used in metal roofing installation:

- Metal shears: Used to cut metal roofing panels.

- Nibblers: Used to cut intricate shapes and curves in metal roofing panels.

- Power drills: Used to drill holes for screws and bolts.

- Screw guns: Used to drive screws into metal roofing panels.

- Nail guns: Used to drive nails into metal roofing panels.

- Metal brakes: Used to bend metal roofing panels.

- Ladders and scaffolding: Used to access and work on metal roofs.

6. What is the importance of proper flashing in metal roofing?

Proper flashing is essential in metal roofing to prevent water from leaking into the building. Flashing is installed at all joints and seams in the metal roofing system, as well as around chimneys, vents, and other roof penetrations.

- Flashing prevents water from seeping behind the metal roofing panels and causing damage to the roof deck or interior of the building.

- Flashing also helps to prevent wind-driven rain from blowing under the metal roofing panels.

7. How do you ensure that metal roofing panels are properly aligned and secured?

To ensure that metal roofing panels are properly aligned and secured, the following steps should be taken:

- Lay out the roofing panels: Start by laying out the roofing panels on the roof deck in the correct order.

- Align the panels: Use a chalk line or string to align the panels correctly.

- Secure the panels: Drive screws or bolts through the panels and into the roof deck at regular intervals.

- Check the alignment: Use a level to check the alignment of the panels after they have been secured.

8. How do you repair a leak in a metal roof?

To repair a leak in a metal roof, the following steps should be taken:

- Locate the leak: Inspect the roof to find the location of the leak.

- Clean the area: Clean the area around the leak with a wire brush to remove any dirt or debris.

- Apply a sealant: Apply a sealant to the leak using a caulking gun.

- Cover the sealant: Cover the sealant with a piece of metal flashing.

- Secure the flashing: Drive screws or bolts through the flashing and into the roof deck.

9. What are the benefits of using metal roofing over other roofing materials?

Metal roofing offers several advantages over other roofing materials:

- Durability: Metal roofs are extremely durable and can last for 50 years or more.

- Fire resistance: Metal roofs are fire-resistant and can help to protect your home from wildfires.

- Energy efficiency: Metal roofs reflect heat away from your home, helping to reduce cooling costs in the summer.

- Low maintenance: Metal roofs require very little maintenance compared to other roofing materials.

- Environmentally friendly: Metal roofs are made from recycled materials and are 100% recyclable at the end of their life.

10. What are the different types of finishes available for metal roofing?

Metal roofing is available in a variety of finishes, each with its own unique look and benefits:

- Galvanized: Galvanized steel is coated with a layer of zinc to protect it from corrosion.

- Galvalume: Galvalume steel is coated with a combination of zinc and aluminum, providing even better corrosion resistance than galvanized steel.

- Painted: Painted metal roofing is available in a wide range of colors and styles.

- Stone-coated: Stone-coated metal roofing has a layer of stone chips applied to the top of the metal, giving it the appearance of a traditional tile roof.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Roofing Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Roofing Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Roofing Mechanics are responsible for installing, repairing, and maintaining metal roofing systems on commercial, industrial, and residential buildings. They work with a variety of metal materials, including steel, aluminum, zinc, and copper, and use specialized tools and equipment to perform their jobs. Key responsibilities include:

1. Installation of New Metal Roofing Systems

Mechanics install new metal roofing systems by following blueprints and specifications. They determine the type and quantity of materials needed for the project, and use specialized equipment to cut, bend, and install the metal roofing panels. They also install flashing, gutters, and downspouts to complete the roofing system.

2. Repair and Maintenance of Existing Metal Roofing Systems

Mechanics repair and maintain existing metal roofing systems by inspecting them for damage, corrosion, or leaks. They identify the source of the problem and make the necessary repairs or replacements. They also perform regular maintenance tasks, such as cleaning the roof, inspecting the seams and flashings, and tightening any loose bolts or screws.

3. Fabrication of Metal Roofing Components

Mechanics fabricate metal roofing components, such as flashing, gutters, and downspouts, using specialized tools and equipment. They follow blueprints and specifications to ensure that the components are made to the correct dimensions and meet the project requirements.

4. Safety Considerations

Mechanics must adhere to all safety regulations and procedures when working on metal roofing systems. They wear appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves, and use caution when working with sharp tools and equipment. They also ensure that the work area is safe and free of hazards.

Interview Tips

To prepare for an interview for a Metal Roofing Mechanic position, candidates should:

1. Research the Company and Position

Candidates should research the company and the specific job position they are applying for. They should learn about the company’s history, culture, and values, as well as the specific duties and responsibilities of the role.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” They should also prepare for questions specific to the metal roofing industry, such as “What types of metal roofing systems have you worked with?” and “What are the most common repairs you have performed on metal roofing systems?”

3. Bring a Portfolio of Previous Work

Candidates should bring a portfolio of their previous work to the interview. This can include photos of projects they have completed, as well as any certifications or awards they have received. A portfolio will demonstrate the candidate’s skills and experience, and will help them stand out from other candidates.

4. Dress Professionally and Be Punctual

Candidates should dress professionally for the interview and arrive on time. This demonstrates respect for the interviewer and the company, and will create a positive first impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Roofing Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!