Feeling lost in a sea of interview questions? Landed that dream interview for Metal Rotary Head Milling Machine Setup Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Rotary Head Milling Machine Setup Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

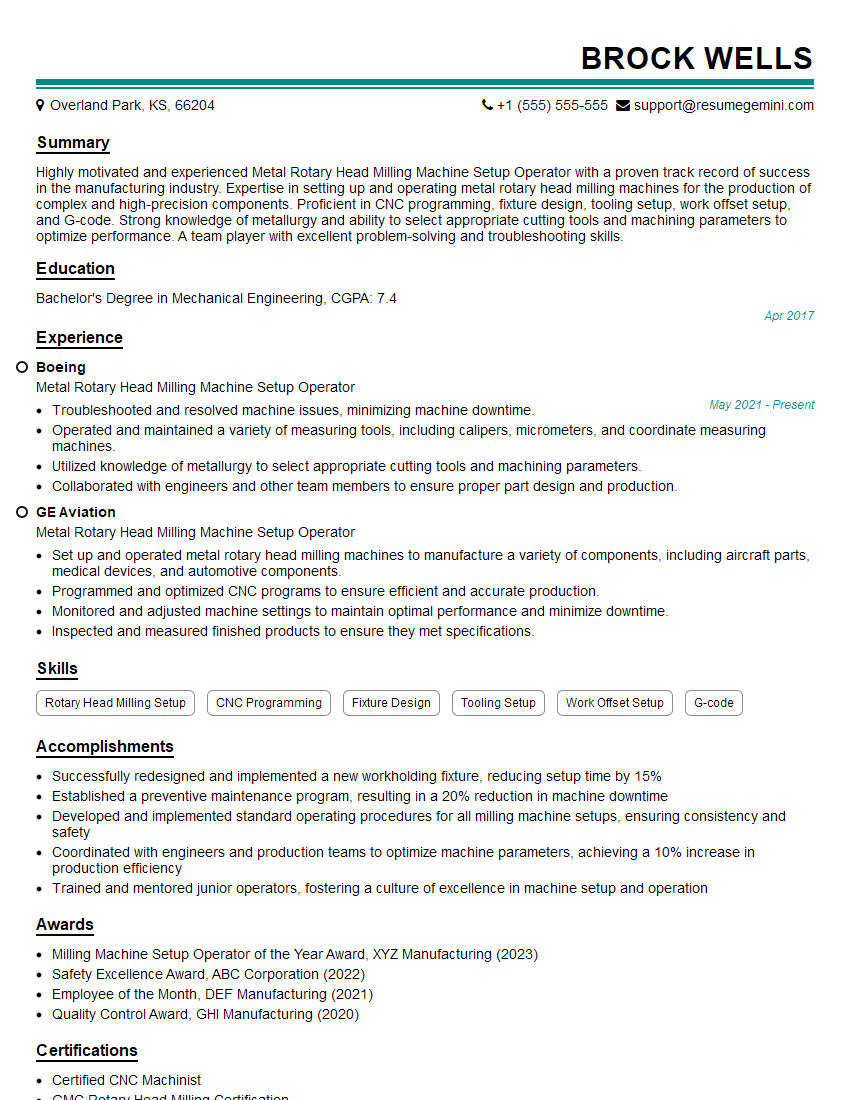

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Rotary Head Milling Machine Setup Operator

1. Explain the steps involved in setting up a rotary head milling machine for a given workpiece.

- Determine the workpiece dimensions and the required machining operations.

- Select the appropriate rotary head attachment and cutting tools for the job.

- Mount the workpiece on the machine table and secure it properly.

- Adjust the rotary head angle and tool position according to the specified machining parameters.

- Set up the feed rates, spindle speed, and coolant flow as per the cutting tool manufacturer’s recommendations.

- Test-run the machine and verify the accuracy of the setup before starting the machining process.

2. How do you calculate the correct feed rate and spindle speed for a given material and cutting tool?

Considering Tool Material

- Identify the material’s hardness and machinability.

- Refer to cutting tool manufacturer’s specifications for recommended feed rates and spindle speeds.

Considering Machine Capabilities

- Check the machine’s maximum spindle speed and torque capacity.

- Ensure the machine can provide the required feed rate for the cutting tool.

- Consider the machine’s rigidity and stability for heavy-duty operations.

Test and Adjustment

- Start with conservative feed rates and spindle speeds.

- Monitor the machining process and adjust the parameters as needed to optimize performance and tool life.

3. What are the different types of coolant systems used in rotary head milling machines?

- Flood coolant: High volume of coolant delivered directly to the cutting zone.

- Mist coolant: Tiny droplets of coolant sprayed onto the cutting zone.

- Cryogenic coolant: Liquid nitrogen or carbon dioxide used to cool the cutting zone.

- Minimum quantity lubrication (MQL): Small amount of oil or other lubricant applied directly to the cutting zone.

- Dry machining: No coolant used, relying on the cutting tool’s coating or workpiece material’s lubricity.

4. Describe the importance of proper tool maintenance for rotary head milling machines.

- Extend tool life: Regular sharpening and inspection can prevent premature tool wear and failure.

- Improve machining accuracy: Sharp and well-maintained tools ensure precise cuts and dimensional accuracy.

- Reduce machine downtime: Proper maintenance reduces the risk of tool breakage, minimizing unplanned interruptions.

- Enhance surface finish: Sharp tools produce a better surface finish on the machined part.

- Maintain machine health: Dull or damaged tools can put strain on the machine, leading to costly repairs.

5. How do you troubleshoot common problems that may occur during rotary head milling operations?

- Excessive tool wear: Check cutting parameters, tool sharpness, and workpiece material hardness.

- Poor surface finish: Verify tool condition, machining parameters, and coolant effectiveness.

- Machine vibration: Inspect machine components for wear or loose connections, balance the workpiece, adjust cutting parameters.

- Tool breakage: Check tool selection, cutting parameters, and workpiece security.

- Coolant issues: Verify coolant supply, nozzle position, and filter cleanliness.

6. What are the safety precautions to be observed when operating a rotary head milling machine?

- Wear appropriate safety gear (e.g., gloves, eye protection, ear protection).

- Secure the workpiece properly to prevent it from becoming a hazard.

- Keep hands and loose clothing away from moving parts.

- Operate the machine only within the specified parameters.

- Monitor the machining process and stop the machine immediately in case of any abnormality.

- Follow lockout/tagout procedures before performing maintenance or repairs.

7. Explain the role of Computer-Aided Manufacturing (CAM) in rotary head milling operations.

- Tool path generation: CAM software creates tool paths for the rotary head, ensuring efficient and accurate machining.

- Simulation: CAM software simulates the machining process before it is executed on the actual machine, reducing the risk of errors.

- Optimization: CAM software can optimize cutting parameters, feed rates, and spindle speeds for enhanced productivity and tool life.

- Integration with CNC machines: CAM software seamlessly integrates with CNC machines to control and monitor the machining process.

8. Describe the advantages of using rotary head milling machines over traditional milling machines.

- Increased flexibility: Rotary heads allow for complex machining operations on curved surfaces or at various angles.

- Improved accuracy: Rotary heads provide better control over tool positioning, resulting in higher precision.

- Reduced setup time: Rotary heads eliminate the need for multiple setups on different axes, saving time.

- Increased productivity: Rotary heads enable continuous machining, reducing cycle times and increasing output.

- Enhanced surface finish: Rotary heads can produce smoother and more consistent surface finishes.

9. Explain the concept of CNC programming for rotary head milling machines.

- G-code and M-code: CNC programming involves using G-codes (geometric commands) and M-codes (miscellaneous commands) to control the machine’s movements.

- Tool path definition: The CNC program defines the path of the rotary head and the cutting tool, including start and end points, feed rates, and spindle speeds.

- Coordinate system: CNC programming uses a coordinate system to specify the positions and movements of the machine and the workpiece.

- Tool selection: The CNC program specifies the type and size of the cutting tool to be used for each machining operation.

- Simulation and optimization: CNC programs can be simulated and optimized before execution to ensure accuracy and efficiency.

10. Describe the different types of materials that can be machined using rotary head milling machines.

- Metals: Ferrous metals (e.g., steel, iron), non-ferrous metals (e.g., aluminum, copper, brass)

- Plastics: Thermoplastics (e.g., ABS, PVC), thermosets (e.g., epoxy, polyester)

- Wood: Hardwoods, softwoods, engineered wood

- Composite materials: Fiber-reinforced plastics, ceramic-matrix composites, metal-matrix composites

- Non-metallic materials: Ceramics, glass, graphite

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Rotary Head Milling Machine Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Rotary Head Milling Machine Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Rotary Head Milling Machine Setup Operator is responsible for setting up, operating, and maintaining a metal rotary head milling machine. This involves a variety of tasks, including:

1. Setup and Operation of Machinery

• Installing and securing workpieces

• Selecting and installing appropriate tooling

• Setting up and operating the machine according to specifications

• Monitoring the machine during operation and making adjustments as needed

2. Maintenance and Troubleshooting

• Performing routine maintenance on the machine, such as lubrication and cleaning

• Troubleshooting and resolving machine problems

• Ordering and replacing parts as needed

3. Quality Control

• Inspecting finished parts to ensure they meet specifications

• Identifying and correcting defects

• Maintaining records of quality control activities

4. Safety

• Following all safety procedures

• Wearing appropriate personal protective equipment

• Maintaining a clean and organized work area

Interview Tips

Preparing for an interview for a Metal Rotary Head Milling Machine Setup Operator position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the company and the position

• Visit the company’s website to learn about their history, products, and services.

• Read online reviews to get a sense of the company’s culture and values.

• Look for job postings for similar positions to get an idea of the qualifications and experience required.

2. Practice your answers to common interview questions

• Read through sample interview questions and practice answering them out loud.

• Focus on highlighting your skills, experience, and qualifications relevant to the position.

• Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Dress professionally and arrive on time

• First impressions matter, so make sure to dress professionally and arrive on time for your interview.

• Be polite and respectful to everyone you meet, including the receptionist and other employees.

4. Be prepared to talk about your experience with metalworking and machining

• Highlight your skills in operating and maintaining metalworking machinery.

• Discuss your experience with different types of materials and machining processes.

• Be prepared to talk about your knowledge of safety procedures and quality control.

5. Be enthusiastic and ask questions

• Show the interviewer that you are excited about the opportunity to work for the company.

• Ask thoughtful questions about the position, the company, and the industry.

• This shows that you are engaged and interested in learning more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Rotary Head Milling Machine Setup Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!