Are you gearing up for an interview for a Metal Sander position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Sander and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

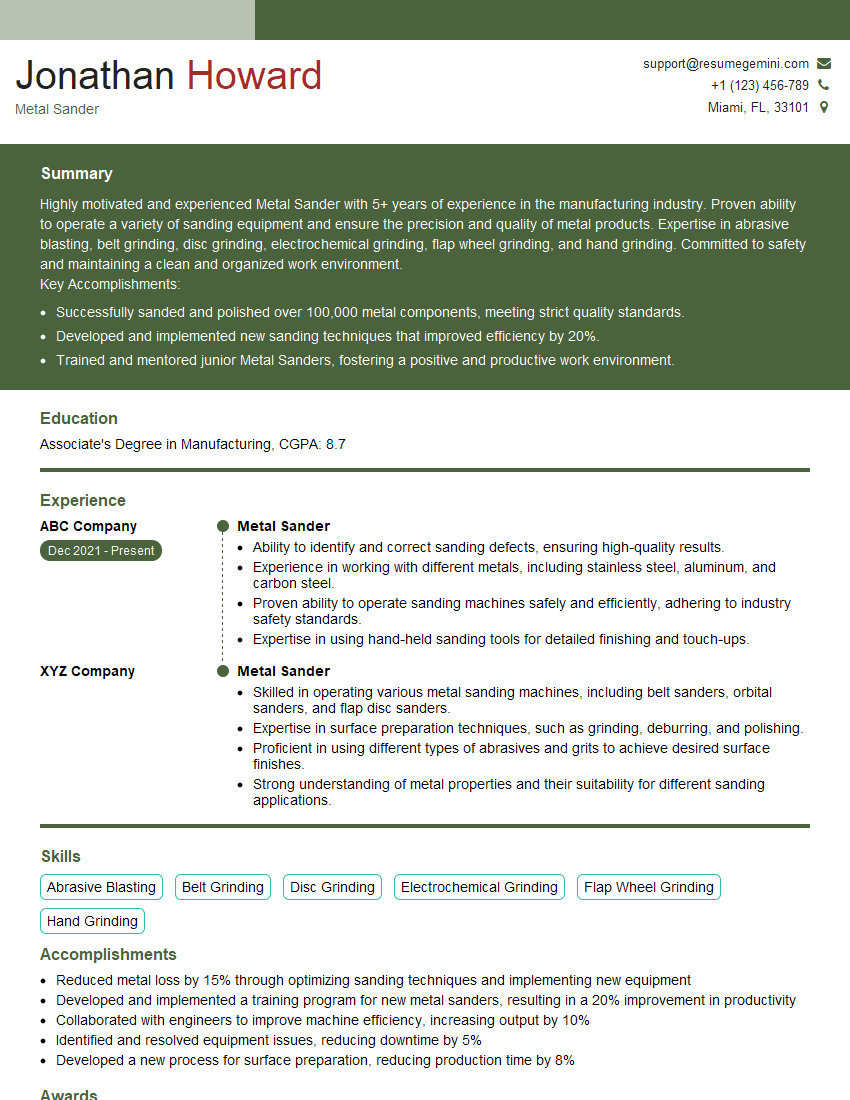

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Sander

1. Explain the different types of grinding wheels used in metal sanding and their applications?

- Aluminium Oxide Wheels: Durable and cost-effective, suitable for general-purpose grinding on ferrous and non-ferrous metals.

- Zirconia Alumina Wheels: Stronger and more aggressive than aluminium oxide, ideal for high-speed grinding of tough materials like steel and stainless steel.

- Silicon Carbide Wheels: Used for grinding non-ferrous metals, such as brass, bronze, and aluminum, due to their sharp and friable nature.

- Ceramic Wheels: Extremely hard and abrasive, providing precision grinding and high material removal rates on hardened materials and ceramics.

- Diamond Wheels: The hardest and most expensive type, designed for grinding extremely hard materials like carbide, glass, and concrete.

2. Describe the recommended safety procedures when operating a metal sander?

Personal Protective Equipment:

- Wear eye protection (safety glasses or goggles)

- Use earplugs or earmuffs

- Wear gloves

- Wear proper clothing, including long sleeves and long pants

Tool Handling:

- Inspect the sander before use for any damage or defects.

- Securely attach the grinding wheel.

- Never operate the sander without the wheel guard.

Work Environment:

- Use the sander in a well-ventilated area.

- Keep the work area clean and free of debris.

- Avoid using the sander near flammable materials.

3. How do you select and change a grinding wheel for a given metal sanding job?

- Determine the Type: Choose a grinding wheel based on the material to be sanded and the desired finish.

- Select the Size: The diameter and thickness of the wheel must match the size of the sander and the job requirements.

- Mounting: Use the appropriate mounting flange and nut to secure the wheel on the sander.

- Safety: Inspect the wheel for any cracks or damage before mounting.

- Installation: Place the wheel on the sander, align the mounting hole, and tighten the nut using a wrench or spanner.

4. How do you determine the correct speed for metal sanding based on the grinding wheel used?

- Read the Wheel Label: Grinding wheels are labeled with their recommended speed range.

- Use a Speed Calculator: Calculate the appropriate speed based on the wheel diameter and material.

- Consider the Material: Softer materials require lower speeds, while harder materials require higher speeds.

- Experience: With practice, you can adjust the speed based on the material, wheel type, and desired finish.

5. Describe the proper techniques for holding and guiding the metal sander during operation?

- Secure Grip: Firmly grasp the sander with both hands, one on the handle and the other on the side.

- Correct Positioning: Position the sander at the desired angle and apply even pressure on the workpiece.

- Controlled Movements: Move the sander smoothly and steadily over the surface, avoiding sudden jerks or excessive force.

- Use Guide Attachments: Utilize guide attachments when necessary to ensure precise cutting or sanding.

- Avoid Overheating: Allow the sander to cool down periodically by lifting it off the workpiece.

6. Explain the different sanding techniques used for various metal surfaces?

- Flat Surface Grinding: Use a flat grinding wheel to remove material evenly from a flat surface.

- Contour Grinding: Use a contoured grinding wheel to grind surfaces with complex shapes or curves.

- Cut-Off Grinding: Use a thin, reinforced cutting-off wheel to cut through metal.

- Buffing: Use a buffing wheel to remove burrs, polish surfaces, or create a satin finish.

- Wire Brushing: Use a wire brush wheel to clean and remove rust or debris from metal surfaces.

7. How do you maintain and troubleshoot common problems encountered with metal sanders?

Maintenance:

- Replace worn or damaged grinding wheels.

- Clean the sander regularly to remove dust and debris.

- Inspect the cords and connections for damage.

- Lubricate moving parts as per manufacturer’s instructions.

Troubleshooting:

- Vibrations: Check for loose bolts or an unbalanced grinding wheel.

- Sparks: Ensure the wheel is rotating in the correct direction and not contacting the work surface too aggressively.

- Noise: Inspect the bearings or gears for damage.

- Overheating: Allow the sander to cool or reduce the grinding pressure.

- Motor Failure: Contact a qualified electrician or service center.

8. Describe the advantages of using a metal sander over other metalworking tools?

- Versatility: Sanding allows for a wide range of operations, including grinding, shaping, cutting, and buffing.

- Efficiency: Sanding can remove material quickly and effectively, saving time and effort.

- Precision: With proper technique, sanding can achieve precise results and smooth finishes.

- Cost-Effectiveness: Sanding is a relatively low-cost metalworking technique compared to other methods.

- Portable: Metal sanders are often portable, allowing for use in various locations.

9. Explain the importance of following safety guidelines when operating a metal sander?

- Prevents Injuries: Proper safety practices minimize the risk of cuts, burns, eye damage, and other injuries.

- Protects Equipment: Adhering to guidelines ensures the longevity of the sander and prevents premature wear or damage.

- Maintains a Safe Work Environment: Proper use and maintenance reduce the risk of fires, explosions, or dust inhalation.

- Complies with Regulations: Following safety protocols ensures compliance with occupational health and safety regulations.

- Protects Reputation: A commitment to safety reflects positively on the company and minimizes the risk of legal liabilities.

10. Describe your experience in operating metal sanders and provide examples of projects you have completed using them?

- Provide a brief overview of your experience with metal sanders, including the types of sanders you have used and the operations you have performed.

- Describe a specific project where you used a metal sander and highlight the challenges you encountered and how you overcame them.

- Discuss the results you achieved and how your sanding skills contributed to the success of the project.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Sanders play a crucial role in shaping and finishing metal components. Their responsibilities encompass:

1. Surface Preparation

Sanding various metal surfaces using power tools like angle grinders and belt sanders.

- Removing rust, paint, and other surface imperfections.

- Smoothing surfaces to prepare for further processing.

2. Cutting and Shaping

Using precision cutting tools such as plasma cutters and oxy-acetylene torches to cut metal.

- Creating precise cuts and shapes for fabrication.

- Trimming and deburring metal edges for a smooth finish.

3. Grinding and Polishing

Using grinding wheels and polishing tools to refine metal surfaces.

- Removing burrs and sharp edges for safety.

- Polishing surfaces to achieve the desired smoothness and finish.

4. Quality Control

Inspecting finished metal products to ensure they meet specifications.

- Checking for defects, dimensional accuracy, and surface finish.

- Ensuring products align with quality standards.

5. Equipment Maintenance

Maintaining and calibrating sanding and cutting equipment for optimal performance.

- Performing routine inspections and cleaning.

- Troubleshooting and resolving equipment issues.

Interview Tips

To ace the Metal Sander interview, consider these preparation tips and hacks:

1. Research the Company and Role

Familiarize yourself with the company’s history, industry, and the specific requirements of the Metal Sander position.

- Visit the company website and LinkedIn profile.

- Review the job description thoroughly, highlighting your relevant skills and experience.

2. Highlight Your Practical Skills

Emphasize your hands-on experience with sanding and cutting tools.

- Provide specific examples of projects or tasks where you demonstrated these skills.

- Quantify your accomplishments, whenever possible, using numbers and metrics.

3. Showcase Your Quality Orientation

Demonstrate your commitment to quality by highlighting your attention to detail and meticulous approach to work.

- Explain how you ensure accuracy and precision in your sanding and cutting operations.

- Share instances where you identified and resolved quality issues.

4. Prepare for Technical Questions

Anticipate technical questions about sanding and cutting techniques, equipment safety, and industry best practices.

- Review the basics of metal sanding and cutting processes.

- Familiarize yourself with the different types of sanding and cutting tools and their applications.

5. Practice the STAR Method

When answering interview questions, use the STAR method to provide structured responses:

- Situation: Briefly describe the context of the scenario.

- Task: Explain your role and responsibilities in the situation.

- Action: Describe the specific actions you took.

- Result: Quantify and highlight the positive outcomes of your actions.

6. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement.

- Inquire about the company’s growth plans and industry outlook.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Sander interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!