Feeling lost in a sea of interview questions? Landed that dream interview for Metal Sheet Roller Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Sheet Roller Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

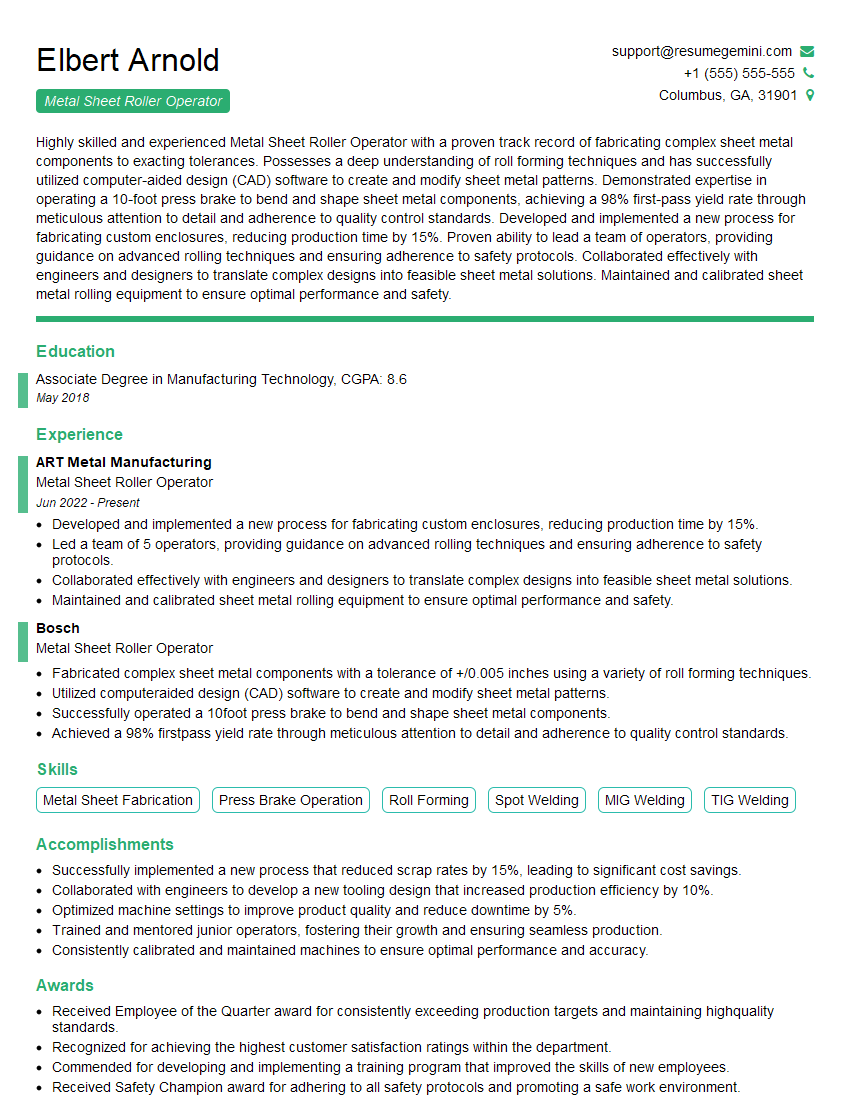

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Sheet Roller Operator

1. How would you ensure the proper alignment of the rolls before the rolling operation?

As a skilled Metal Sheet Roller Operator, the proper alignment of the rolls is crucial for precise rolling. To achieve this, I follow these steps:

- Inspect the rolls for any damage or wear that could affect alignment.

- Use a dial indicator or other precision instrument to measure and adjust roll spacing to meet specifications.

- Ensure that the rolls are parallel to each other and perpendicular to the direction of sheet travel.

- Lock the rolls securely in place to prevent any movement during the rolling process.

2. Describe the different types of roll configurations available and their applications.

Pyramid Rolls

- Ideal for producing conical or tapered shapes.

- Used in applications such as rolling cones, drums, and funnels.

Slitting Rolls

- Designed to cut metal sheets into narrow strips.

- Used in industries like packaging and printing for producing labels, ribbons, and other narrow sheet products.

Curvature Rolls

- Used for creating curved or cylindrical shapes.

- Applications include rolling pipes, tubes, and vessels.

3. Explain the factors that influence the surface finish of the rolled sheet.

- Roll Surface: Rough surfaces produce rougher finishes, while smooth surfaces yield smoother finishes.

- Sheet Thickness: Thinner sheets are more prone to surface imperfections due to increased deformation.

- Rolling Speed: Higher speeds reduce the time for proper deformation, leading to a less smooth finish.

- Lubrication: Proper lubrication reduces friction and improves surface quality.

4. How do you avoid sheet buckling or wrinkling during the rolling process?

- Proper Roll Gap: Setting the correct gap between the rolls prevents excessive material deformation.

- Gradual Rolling: Rolling in multiple passes with gradually reduced gaps reduces stress and buckling.

- Support Rollers: Using support rollers along the length of the sheet provides stability and prevents bending.

- Lubrication: Lubrication reduces friction and helps the sheet move smoothly through the rolls.

5. What are the key safety precautions to observe when operating a metal sheet roller?

- Proper Training: Only trained and authorized operators should handle the equipment.

- Protective Gear: Wear safety glasses, gloves, and proper clothing to prevent injuries.

- Guarding: Ensure that all moving parts are properly guarded to prevent entanglement or contact.

- Emergency Stop: Familiarize yourself with the emergency stop controls and their location.

- Lockout/Tagout: Perform lockout/tagout procedures before any maintenance or repairs.

6. How do you maintain the accuracy and precision of your rolling operations?

- Regular Calibration: Calibrate the machine regularly to ensure accurate measurements and settings.

- Precision Tools: Use precision instruments, such as dial indicators and gauges, to measure and verify dimensions.

- Quality Control: Implement a quality control system to monitor and maintain product quality.

- Training: Continuously train operators on proper techniques and best practices to enhance accuracy and precision.

7. How do you optimize the rolling process for different types of metal alloys?

- Material Properties: Understand the specific properties of the alloy, such as yield strength, ductility, and workability.

- Roll Selection: Choose appropriate rolls based on the alloy’s characteristics and desired surface finish.

- Process Parameters: Adjust rolling speed, temperature, and lubrication according to the alloy’s requirements.

- Experience and Expertise: Leverage knowledge and experience to optimize the process for specific alloys.

8. What troubleshooting techniques do you use when encountering problems during rolling?

- Identify the Problem: Determine the source of the issue, whether it’s alignment, roll wear, or material defects.

- Check Equipment: Inspect the machine for any mechanical or electrical problems that may affect performance.

- Adjust Parameters: Make necessary adjustments to rolling speed, roll gap, or lubrication to optimize the process.

- Seek Assistance: If the problem persists, consult with a supervisor or experienced technician for support.

9. How do you ensure the rolled sheets meet the desired specifications?

- Detailed Specifications: Obtain clear and complete specifications from the customer or production plan.

- Measurement and Inspection: Use appropriate measuring tools and gauges to verify dimensions, thickness, and surface quality.

- Calibration and Maintenance: Ensure that measuring instruments are calibrated, and the machine is properly maintained to provide accurate measurements.

- Quality Control: Implement a quality control system to monitor and maintain product quality throughout the rolling process.

10. Describe the different types of rolling defects and how you would identify and correct them.

Roll Marks

- Cause: Worn or damaged rolls.

- Identification: Visible marks or scratches on the rolled surface.

- Correction: Replace or repair the rolls.

Edge Cracks

- Cause: Excessive roll pressure or sharp edges on the sheet.

- Identification: Cracks or tears along the sheet edges.

- Correction: Adjust roll pressure, chamfer sheet edges, or use edge guides.

Buckling

- Cause: Improper roll gap or insufficient lubrication.

- Identification: Waves or buckles on the rolled surface.

- Correction: Adjust roll gap, increase lubrication, or use support rollers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Sheet Roller Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Sheet Roller Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Sheet Roller Operators oversee every aspect of metal sheet rolling, ensuring consistent production quality, safety standards, and equipment maintenance.

1. Sheet Processing Setup

Prepare metal sheets for rolling by verifying specifications, selecting appropriate rollers, and adjusting machine settings.

2. Operation and Monitoring

Operate rolling machinery to form metal sheets into desired shapes and dimensions, consistently monitoring gauges to maintain accurate measurements.

3. Equipment Maintenance

Maintain and calibrate rolling equipment, ensuring optimal performance and safety. Inspect machines regularly, perform lubrication and adjustments, and report any repairs or upgrades.

4. Quality Control

Conduct dimensional and visual inspections to ensure the quality of finished sheets meet specifications. Identify and correct errors promptly, maintaining high production standards.

Interview Tips

Acing a Metal Sheet Roller Operator interview requires thorough preparation and demonstration of relevant skills and knowledge.

1. Research the Company and Industry

Familiarize yourself with the company’s operations, industry trends, and specific metal sheet rolling practices to demonstrate your understanding and interest.

2. Practice Technical Knowledge

Review the principles of metal rolling, types of machinery, and safety protocols. Be prepared to discuss your understanding and experience in operating and maintaining sheet rolling equipment.

3. Highlight Safety and Quality Control

Emphasize your commitment to maintaining a safe work environment and ensuring product quality by following established procedures and standards.

4. Showcase Problem-Solving Abilities

Share examples of how you have successfully troubleshooting rolling issues, resolved equipment malfunctions, and improved production efficiency. Discuss your problem-solving approach and how you prioritize tasks.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Sheet Roller Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!