Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Tank Erector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

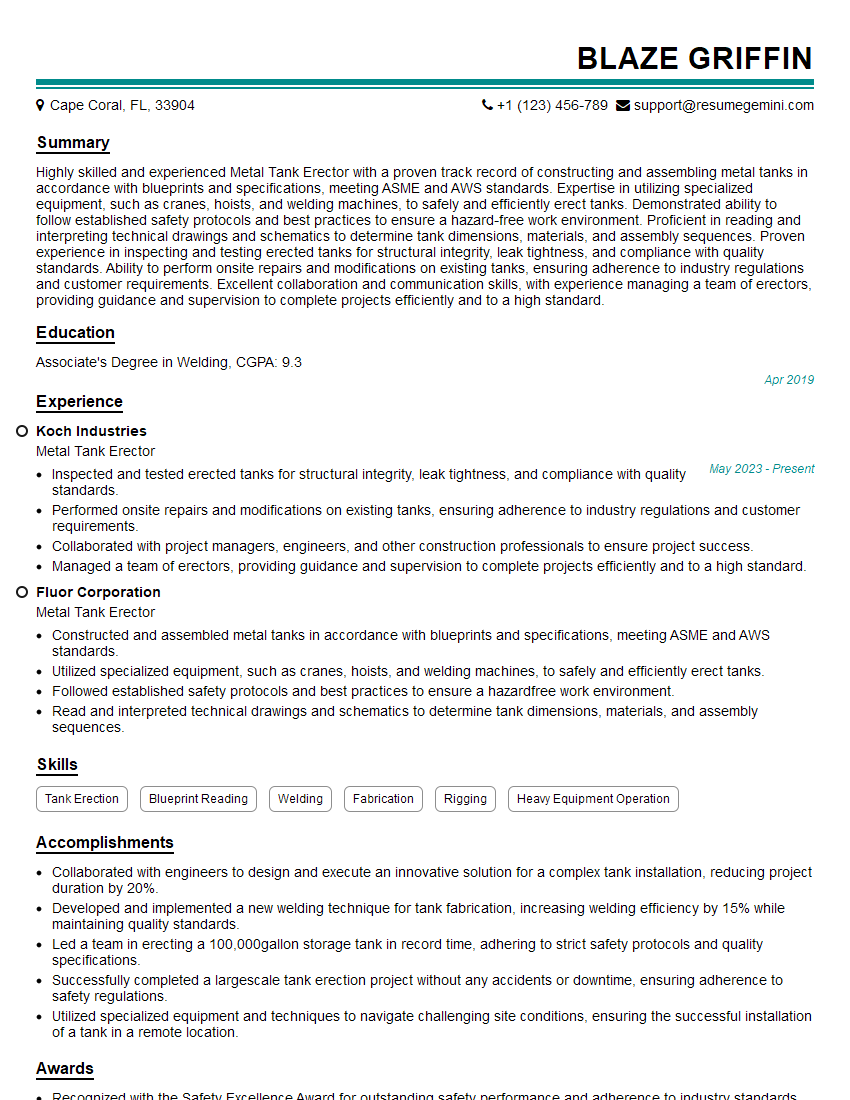

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Tank Erector

1. What are the different types of metal tanks and their applications?

Metal tanks come in various types, each with specific applications:

- Atmospheric tanks: Designed to store liquids and gases at atmospheric pressure, commonly used in industries such as oil and gas.

- Pressure vessels: Constructed to withstand higher pressures, used in applications where pressurization is required, e.g., boilers and compressed gas storage.

- Cryogenic tanks: Specialized tanks for storing liquified gases at extremely low temperatures, found in industries like aerospace and medical.

- Underground storage tanks (USTs): Buried tanks commonly used for storing hazardous liquids or petroleum products in residential and commercial settings.

- Agricultural tanks: Tanks specifically designed for agricultural purposes, such as storing fertilizers, pesticides, or liquid feed.

2. Explain the process of erecting a metal tank, including the equipment and safety measures involved.

Erecting a metal tank involves several steps:

- Site preparation: Clearing the area, leveling the ground, and establishing a stable foundation.

- Tank assembly: Joining the individual metal sheets to form the tank shell and installing the necessary nozzles, manholes, and other components.

- Equipment: Cranes, welding equipment, cutting tools, and scaffolding are commonly used.

- Safety measures: Proper personal protective equipment (PPE), lifting procedures, and adherence to safety regulations are essential.

- Testing and inspection: Conducting hydrostatic or pneumatic tests to verify tank integrity and ensure compliance with industry standards.

3. How do you ensure the quality and accuracy of the welding process when erecting a metal tank?

- Qualified welders: Employing certified and experienced welders who adhere to stringent welding standards.

- Proper welding techniques: Using appropriate welding methods and selecting the correct welding parameters.

- Non-destructive testing (NDT): Conducting tests such as radiography, ultrasonic testing, or magnetic particle inspection to identify any defects or discontinuities in the welds.

- Weld maps and documentation: Maintaining detailed records of welding procedures and inspections for traceability and quality control.

- Compliance with codes: Ensuring that welding practices meet industry regulations and codes, such as ASME or AWS.

4. Describe the importance of maintaining a clean work environment when erecting a metal tank.

Maintaining a clean work environment is crucial for several reasons:

- Quality control: Dirt and debris can contaminate the welding process, leading to poor weld quality and potential failures.

- Safety: A clean environment minimizes tripping hazards, slips, and other accidents.

- Efficiency: A clear workspace enables efficient movement of equipment and materials, reducing project delays.

- Equipment protection: Keeping welding equipment clean extends its lifespan and prevents malfunctions.

- Inspection: A clean tank surface facilitates thorough inspections and ensures that welds and other components meet specifications.

5. How do you handle challenges and resolve problems that arise during metal tank erection?

- Problem identification: Promptly identifying the root cause of any issues or challenges that arise on-site.

- Consultation: Seeking advice from experienced colleagues, supervisors, or engineers to develop effective solutions.

- Alternative methods: Exploring alternative approaches or techniques to overcome obstacles while maintaining quality standards.

- Communication: Maintaining open communication with stakeholders, including clients and inspectors, to keep them informed of any issues and proposed solutions.

- Continuous improvement: Using troubleshooting experiences as opportunities to enhance processes and prevent similar challenges in the future.

6. How do you stay updated on the latest industry standards and best practices related to metal tank erection?

- Industry seminars and conferences: Attending industry events to learn about new techniques, regulations, and advancements.

- Trade publications and journals: Reading industry-specific publications to stay abreast of current trends and practices.

- Online resources: Utilizing online platforms and databases to access technical information, case studies, and best practice guidelines.

- Training and certifications: Participating in training programs and obtaining industry certifications to demonstrate expertise and knowledge.

- Collaboration: Engaging with colleagues, industry professionals, and suppliers to share knowledge and exchange best practices.

7. What are some of the safety hazards associated with metal tank erection and how do you mitigate them?

- Fall hazards: Implementing fall protection measures such as scaffolding, harnesses, and guardrails.

- Welding fumes: Using proper ventilation and respiratory protection equipment to protect against harmful fumes.

- Heavy equipment: Establishing safe operating procedures and ensuring proper training for equipment operators.

- Electrical hazards: Ensuring proper insulation, grounding, and following safe electrical practices.

- Confined space hazards: Implementing proper safety protocols and training for working in confined spaces, such as tank interiors.

8. Explain the importance of proper documentation and record-keeping during metal tank erection.

- Quality control: Records provide evidence of compliance with specifications and industry standards.

- Liability: Documentation serves as proof of work completed and adherence to safety protocols.

- Traceability: Records allow for tracking materials, welding procedures, and inspections for future reference.

- Troubleshooting: Documentation aids in identifying issues and resolving problems during tank erection.

- Historical data: Records provide valuable information for future projects and continuous improvement.

9. Describe your experience in working with different types of materials used in metal tank erection.

Carbon steel

- Versatile material with excellent strength-to-weight ratio.

- Commonly used in atmospheric tanks and pressure vessels.

- Requires proper surface preparation and corrosion protection measures.

Stainless steel

- Corrosion-resistant and durable material.

- Suitable for applications involving food processing, chemicals, and pharmaceuticals.

- Requires specialized welding techniques and considerations.

Aluminum

- Lightweight and corrosion-resistant material.

- Used in applications where weight reduction is critical, such as aerospace and transportation.

- Requires specific welding techniques and surface treatments.

10. How do you work effectively as part of a team during metal tank erection projects?

- Communication: Maintaining clear and open communication with team members to ensure coordination and avoid misunderstandings.

- Collaboration: Working cooperatively with colleagues to solve problems, share knowledge, and support each other’s work.

- Safety: Prioritizing safety by adhering to safety protocols and looking out for the well-being of team members.

- Flexibility: Adapting to changing project requirements and adjusting responsibilities as needed to support the team’s goals.

- Respect: Valuing the contributions and perspectives of all team members, regardless of their role or experience level.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Tank Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Tank Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Tank Erector is an individual who is responsible for assembling, erecting, maintaining, and repairing metal tanks. The key job responsibilities of a Metal Tank Erector include:1. Tank Construction

The metal tank erector should be able to assemble, erect and build various types of metal tanks.

- Assembling and erecting metal tanks of various sizes and shapes.

- Welding and riveting metal components to create a watertight and airtight seal.

2. Tank Inspection and Maintenance

He should inspect and maintain the tank regularly to ensure there are no damage and repairs required

- Conduct regular inspections of tanks to identify any damage or potential problems.

- Performing maintenance tasks such as cleaning, repainting, and replacing worn or damaged parts.

3. Safety Compliance

It is the responsibility of the erector to maintain proper safety measures while working

- Adhering to safety regulations and guidelines to ensure a safe work environment.

- Wearing appropriate personal protective equipment (PPE) while working.

4. Knowledge of Blueprint and Schematics

Knowledge of blueprints and schematics is essential for a metal tank erector to understand the tank structure and specifications

- Reading and interpreting blueprints and schematics to understand the design and specifications of the tank.

- Following the instructions and specifications outlined in the blueprints to ensure accurate construction.

Interview Tips

Preparing for a job interview is essential to showcase your skills and qualifications. Here are some interview tips to help you prepare for your interview as a Metal Tank Erector:1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will show the interviewer that you are interested in the company, the role and are prepared.

- Visit the company’s website to learn about their history, mission, and values.

- Check the job description carefully to understand the key responsibilities and requirements of the role.

2. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the role of a Metal Tank Erector.

- Quantify your accomplishments using specific examples and numbers.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

3. Prepare for Common Interview Questions

Prepare for common interview questions that you may be asked during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position.

- Ask questions about the company’s culture and work environment.

- Inquire about the growth opportunities and advancement possibilities within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Tank Erector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.