Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

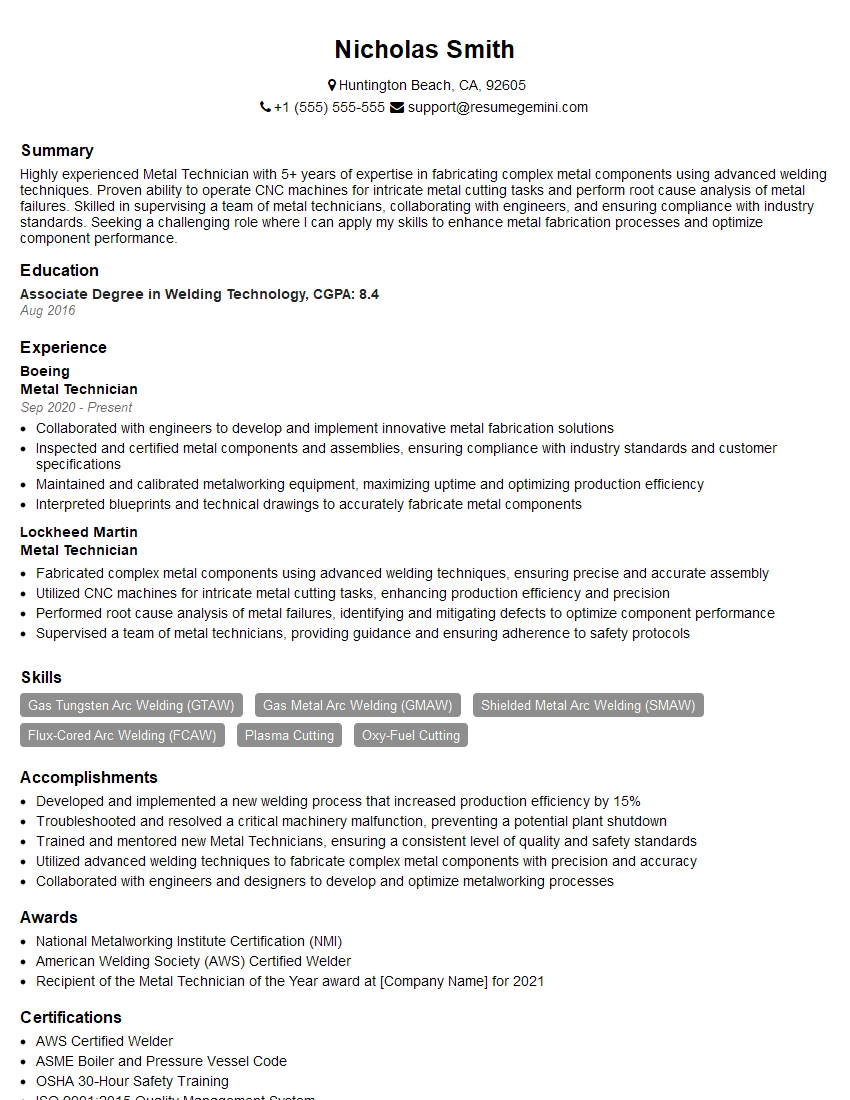

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Technician

1. How do you ensure the accuracy of metal cutting operations?

To ensure the accuracy of metal cutting operations, I follow a systematic approach that includes:

- Proper machine setup: I carefully calibrate and align the cutting machine according to the specified tolerances.

- Precise tool selection: I select the appropriate cutting tool based on the material, thickness, and desired finish.

- Optimized cutting parameters: I determine the optimal cutting speed, feed rate, and depth of cut to achieve the desired accuracy.

- Regular tool inspection: I inspect the cutting tools for wear and damage to prevent inaccuracies.

- Continuous monitoring: I closely monitor the cutting process and make adjustments as needed to maintain precision.

2. Describe the different welding techniques you are proficient in and their applications.

Arc Welding

- SMAW (Stick Welding): Manual process known for its versatility and affordability; used in various industries for heavy-duty fabrication.

- MIG (Gas Metal Arc Welding): Semi-automatic process with a continuously fed electrode; suitable for high-volume welding applications.

- TIG (Gas Tungsten Arc Welding): Precision process that provides high-quality welds; ideal for delicate and intricate work.

Resistance Welding

- Spot Welding: Creates localized welds using pressure and electrical current; used for thin metal sheets.

- Seam Welding: Continuous welding along a seam using rotating electrodes; commonly used in the automotive industry.

3. How do you inspect metal components for defects?

I employ various methods to inspect metal components for defects:

- Visual Inspection: Examining the component’s surface for visible flaws, such as cracks, corrosion, or distortions.

- Dimensional Inspection: Using measuring tools to verify that the component meets specified dimensions and tolerances.

- Hardness Testing: Determining the material’s hardness using a Rockwell or Brinell tester to ensure it meets design requirements.

- Dye Penetrant Testing: Applying a penetrant to reveal surface cracks and discontinuities.

- Ultrasonic Testing: Using high-frequency sound waves to detect internal defects, such as porosity or delaminations.

4. What are the safety precautions you take when working with metals?

I prioritize safety by adhering to these precautions:

- Proper Personal Protective Equipment: Wearing appropriate gloves, safety glasses, a welding helmet, and protective clothing to prevent injuries.

- Ventilation: Ensuring adequate ventilation to remove welding fumes and other hazardous substances.

- Fire Prevention: Keeping a fire extinguisher nearby and clearing away flammable materials from the work area.

- Electrical Safety: Inspecting equipment regularly and using proper grounding to prevent electrical shocks.

- Proper Lifting Techniques: Using proper body mechanics and equipment when lifting heavy metal objects to avoid strain or injury.

5. Describe your experience with heat treatment processes for metals.

I have extensive experience with various heat treatment processes for metals, including:

- Annealing: Heating metal to a specific temperature followed by slow cooling to soften it and improve machinability.

- Hardening: Heating metal to a high temperature and quenching it rapidly to increase its hardness and strength.

- Tempering: Heating hardened metal to a lower temperature to reduce brittleness and improve toughness.

- Carburizing: Increasing the carbon content of the metal’s surface to enhance wear resistance.

- Stress Relief: Reducing internal stresses in metal components to prevent deformation or cracking.

6. How do you stay up-to-date with the latest advancements in metalworking techniques?

I actively engage in continuous learning to stay informed about the latest advancements in metalworking techniques:

- Industry Publications: Subscribing to trade magazines and journals to read articles on emerging technologies and best practices.

- Conferences and Workshops: Attending industry events to network with experts and learn about innovative techniques.

- Online Resources: Utilizing online platforms, technical forums, and vendor websites to access technical information and case studies.

- Manufacturer Training: Participating in training programs offered by equipment manufacturers to gain specialized knowledge on their products and technologies.

7. Explain the different types of cutting fluids used in metalworking and their purposes.

- Water-Based Fluids: Soluble oil and synthetic emulsions; provide cooling, lubrication, and corrosion protection.

- Oil-Based Fluids: Straight, neat oils; offer high lubrication and film strength, but can be less effective for cooling.

- Chemical Fluids: Often synthetic; provide excellent cooling and lubrication, but require special handling and disposal.

- Gas-Assisted Cutting: Using inert gases like nitrogen or argon; enhances cooling and reduces friction.

- Cryogenic Fluids: Liquid nitrogen or carbon dioxide; provide extreme cooling, reducing tool wear and improving surface finish.

8. How do you troubleshoot common problems encountered in metal fabrication?

When troubleshooting common problems in metal fabrication, I follow a systematic approach:

- Identify the Problem: Determine the specific issue and its symptoms.

- Analyze the Process: Review the work instructions, materials used, and equipment settings.

- Inspect the Equipment: Check for any signs of wear, damage, or misalignment.

- Adjust or Repair: Implement corrective actions, such as adjusting parameters, replacing worn parts, or calibrating equipment.

- Test and Verify: Run trial operations to confirm that the problem has been resolved.

9. Describe the importance of maintaining accurate records in metalworking.

Accurate records in metalworking are crucial for:

- Quality Control: Documenting parameters, materials used, and inspection results to ensure compliance with specifications.

- Traceability: Tracking the history of metal components for quality assurance and liability purposes.

- Process Improvement: Identifying areas for optimization by analyzing production data and identifying trends.

- Knowledge Sharing: Preserving technical information and best practices for future reference.

- Regulatory Compliance: Maintaining records as required by industry standards and regulations.

10. How do you handle working in a team environment and collaborating with other departments?

I thrive in a team environment and actively collaborate with other departments to achieve shared goals:

- Communication: Regularly communicate with team members, supervisors, and other stakeholders to ensure everyone is informed and aligned.

- Problem-Solving: Contribute ideas and participate in brainstorming sessions to find solutions to complex challenges.

- Cross-Functional Coordination: Work closely with departments such as engineering, design, and quality control to ensure smooth project execution.

- Knowledge Sharing: Share expertise and best practices with colleagues to enhance overall team performance.

- Adaptability: Willingly adjust my work style and priorities to complement the team’s needs and objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Technicians are responsible for working with a variety of metals to create and repair products. They may also be responsible for operating machinery such as lathes, mills, and grinders.

1. Fabricate Metal Products

Metal Technicians may be required to fabricate metal products according to design specifications.

- Cut, shape, weld, and assemble metal components.

- Use a variety of tools and techniques to create metal products.

2. Repair Metal Products

Metal Technicians can be responsible for repairing metal products such as machinery, vehicles, and appliances.

- Diagnose and repair problems with metal products.

- Replace damaged parts and components.

3. Operate Machinery

Metal Technicians may be required to operate machinery such as lathes, mills, and grinders.

- Set up and operate machinery to perform specific tasks.

- Maintain and adjust machinery to ensure optimal performance.

4. Maintain a Safe Work Environment

Metal Technicians must be aware of and follow safety procedures when working with metals and machinery.

- Wear appropriate personal protective equipment.

- Keep work area clean and organized.

Interview Tips

Metal Technicians should be prepared to discuss their experience working with metals, machinery, and safety procedures.

1. Research the Company

Before your interview, research the company you are applying to. This will help you understand their business, products, and services. You will also be able to learn about the company culture and what it is like to work there.

- Visit the company website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Your Answers

Once you have researched the company, you can start practicing your answers to common interview questions. For example, you might be asked to tell me about yourself, why are you interested in this position, and what are your strengths and weaknesses?

- Write out your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Be Yourself

The most important thing is to be yourself in your interview. The interviewer wants to get to know the real you, so don’t try to be someone you are not. Just be confident and articulate, and the interviewer will be able to see your skills and qualities.

- Don’t try to be someone you are not.

- Be confident and articulate.

- Show the interviewer your skills and qualities.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are serious about the opportunity.

- Ask about the position and the company.

- Show that you are interested in the position.

- Demonstrate that you are serious about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!