Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Temperer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

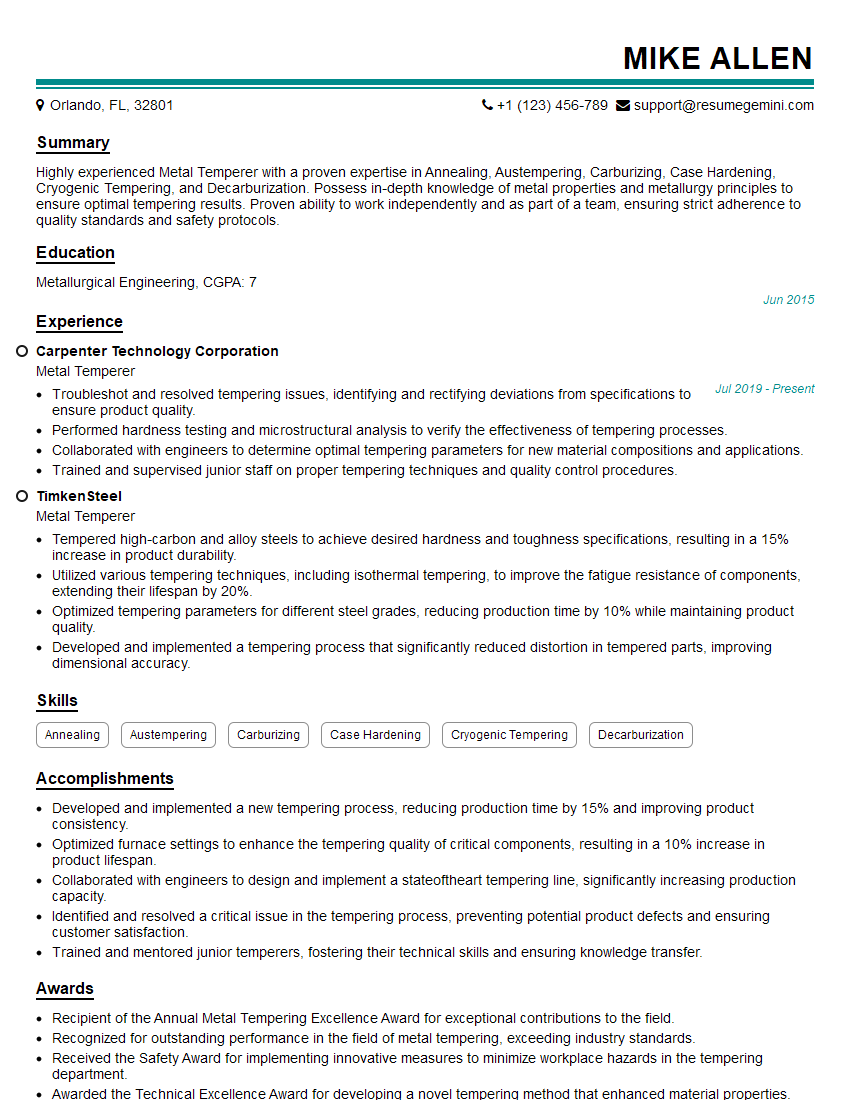

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Temperer

1. Describe the process of tempering metal, and explain how it affects the properties of the metal?

- Tempering is a heat treatment process that involves heating metal to a specific temperature below its melting point and then cooling it at a controlled rate.

- This process helps to relieve internal stresses in the metal, improve its toughness, and increase its ductility by reducing hardness and increasing softness.

- Tempering temperature and duration influence the final properties of the metal

2. What are the different types of tempering methods?

Austempering

- Involves quenching the metal in a molten bath (often salt or lead) at a temperature above the martensite start temperature but below the bainite start temperature.

- This results in a microstructure consisting of bainite, which has better toughness and strength than martensite.

Martempering

- Similar to austempering, but the metal is quenched into a molten bath at a temperature slightly above the martensite start temperature.

- This results in a microstructure consisting of a mixture of martensite and bainite, providing a combination of strength and toughness.

Sub-zero tempering

- Involves cooling the metal to very low temperatures (-100°C or below) after quenching.

- This helps to transform any remaining austenite into martensite, resulting in improved hardness and wear resistance.

3. How do you determine the appropriate tempering temperature for a given metal?

- Consider the desired properties for the metal, such as hardness, toughness, and ductility.

- Refer to tempering charts or consult with metallurgists to determine the recommended temperature range for the specific metal and alloy.

- Conduct tests to fine-tune the tempering temperature and evaluate the resulting properties.

4. What are the common defects that can occur during tempering, and how can they be prevented?

- Overtempering: Occurs when the metal is tempered at too high a temperature or for too long, resulting in reduced hardness and strength.

- Undertempering: Occurs when the metal is tempered at too low a temperature or for too short a time, resulting in insufficient stress relief and potential embrittlement.

- Quenching cracks: Can occur if the metal is cooled too rapidly during quenching, causing internal stresses and cracking.

- Prevention: Proper temperature control, appropriate cooling rates, and preheating the metal before quenching can help prevent these defects.

5. How do you measure the hardness of tempered metal?

- Rockwell hardness test: Measures the depth of indentation made by a diamond or tungsten carbide indenter under a specific load.

- Vickers hardness test: Similar to the Rockwell test, but uses a square-based diamond indenter and calculates hardness based on the area of the indentation.

- Brinell hardness test: Measures the diameter of an indentation made by a steel ball under a specific load.

6. What are the safety precautions that should be taken when tempering metal?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Ensure proper ventilation to remove any fumes or gases released during the process.

- Handle hot metal with care, using tongs or heat-resistant gloves.

- Be aware of potential fire hazards and have a fire extinguisher nearby.

- Follow established safety protocols and guidelines.

7. What are the advantages of using induction heating for tempering metal?

- Precise temperature control: Induction heating allows for precise control of the heating process, ensuring uniform tempering.

- Rapid heating: Induction heating rapidly heats the metal, reducing processing time.

- Energy efficiency: Induction heating is energy-efficient as it generates heat directly in the metal without significant heat loss to the surroundings.

- Reduced distortion: Induction heating minimizes thermal distortion and warping of the metal due to its localized heating.

8. Explain the role of alloying elements in the tempering process of steel?

- Alloying elements, such as carbon, manganese, and chromium, influence the phase transformations and precipitation reactions that occur during tempering.

- These elements can form carbides and other precipitates that contribute to the strength, hardness, and toughness of the tempered steel.

- By controlling the alloy composition and tempering parameters, specific properties can be tailored for different applications.

9. Describe the equipment used in a typical tempering furnace?

- Heating chamber: Where the metal is placed for tempering

- Temperature control system: Regulates the temperature inside the chamber

- Circulation system: Ensures uniform heating throughout the chamber

- Cooling system: Controls the cooling rate of the metal after tempering

- Safety features: Includes over-temperature protection, smoke detectors, and emergency stop buttons

10. Explain the importance of quality control in the tempering process?

- Quality control ensures that the tempered metal meets the desired specifications and performance requirements.

- It involves testing the metal’s hardness, microstructure, and other properties to verify its quality.

- Proper quality control helps prevent defects, maintains product consistency, and ensures the reliability and safety of the tempered metal.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Temperer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Temperer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Temperers are responsible for ensuring that metal components meet the required level of hardness, strength and durability. Their duties include:

1. Tempering Metal Components

Using specialized equipment such as furnaces and quenching tanks, they heat and cool metal components. The purpose of tempering is to alter the metal’s microstructure and improve its properties.

2. Monitoring and Controlling Processes

Metal Temperers are required to monitor and control all stages of the tempering process. This includes monitoring temperature, time and cooling rates. They need to ensure the process adheres to the relevant industry standards and specifications.

3. Inspecting and Testing Metal Components

After tempering, they inspect and test metal components to ensure they meet the required quality standards. They may use various testing methods, including hardness testing, tensile testing, and microscopy.

4. Maintaining Equipment

They maintain the equipment used in the tempering process, ensuring it is in good working condition. They perform regular maintenance tasks such as calibration, cleaning, and repairs.

5. Working as Part of a Team

Metal Temperers collaborate with other team members, including engineers, metallurgists, and quality control personnel. They follow instructions and work together to achieve the desired outcomes.

Interview Tips

Preparing well for an interview can significantly improve your chances of success. Here are some tips to help you ace your interview for a Metal Temperer position:

1. Research the Company and Position

Before the interview, take the time to research the company you are applying to and the specific Metal Temperer position. Learn about their products, services, industry, and company culture. This knowledge will help you answer questions intelligently and show that you are genuinely interested in the opportunity.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is beneficial to practice answering these questions beforehand so that you can deliver well-thought-out and confident responses. Some typical questions include:

- Tell me about your experience in metal tempering.

- What are the different types of tempering processes?

- How do you ensure that the metal components meet the required specifications?

- What are the safety precautions that you take when working with metal tempering equipment?

3. Tailor Your Answers to the Job Description

When answering interview questions, make an effort to tailor your responses to the specific requirements of the job description. Highlight your skills and experience that are most relevant to the position. For instance, if the job description emphasizes the use of a particular tempering technique, be sure to mention your proficiency in that technique during the interview.

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company’s culture and values. Some questions you could ask include:

- What is the company’s commitment to quality and safety?

- What are the opportunities for professional development and advancement within the company?

- What are the company’s goals for the future?

5. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time to show that you are respectful of the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Temperer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.