Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Treater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

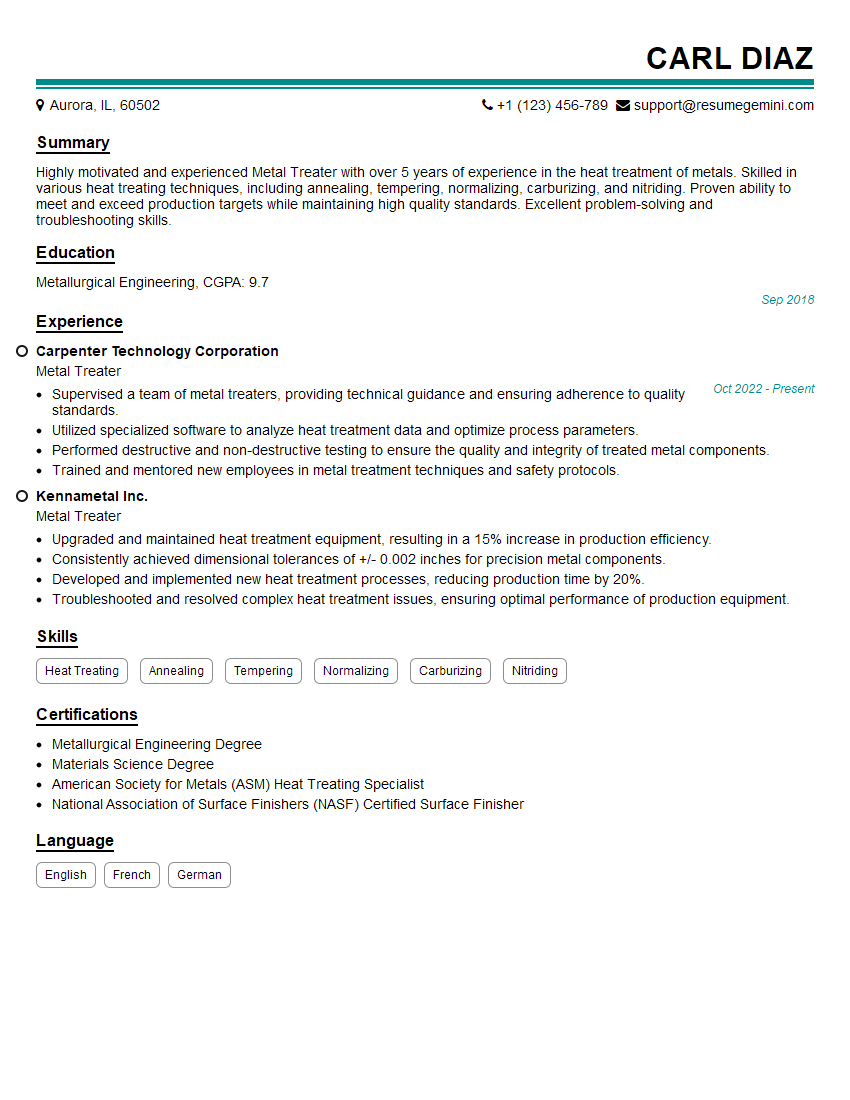

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Treater

1. What are the different types of metal treatments and their applications?

There are various metal treatments, each with specific applications:

- Annealing: Softens metals by heating and slowly cooling, increasing ductility and toughness. Used for sheet metal forming and wire drawing.

- Quenching: Hardens metals by rapidly cooling heated metal, increasing strength but reducing ductility. Used for tools, springs, and cutlery.

- Tempering: Relieves stresses and brittleness in quenched metals. Improves toughness while maintaining hardness. Used for heat-treated components.

- Case Hardening: Hardens only the surface of metal while keeping the core ductile. Used for gears, shafts, and bearings.

- Nitriding: Diffuses nitrogen into the surface of metal, improving wear resistance and fatigue strength. Used for aircraft components, automotive parts, and cutting tools.

2. Describe the process of heat treatment for steel and its effects on the material properties.

Annealing

- Heated to a specific temperature and then slowly cooled.

- Softens steel, making it more ductile and less brittle.

- Used for applications where formability and toughness are important.

Quenching

- Heated to a specific temperature and then rapidly cooled.

- Hardens steel, increasing its strength and wear resistance.

- Used for applications where hardness and durability are critical.

Tempering

- Heated to a specific temperature below the hardening temperature and then cooled.

- Reduces brittleness and improves toughness.

- Used to achieve a balance between strength and toughness.

3. How do you determine the appropriate heat treatment process and parameters for a given metal and its intended application?

Factors to consider:

- Metal composition: Alloys and carbon content affect heat treatment response.

- Desired properties: Determine the required mechanical properties (e.g., strength, hardness, toughness).

- Application: Consider the operating environment and stresses the metal will encounter.

- Heat treatment equipment: Available equipment dictates the achievable temperatures and cooling rates.

- Experience and industry standards: Refer to established guidelines and consult experts for best practices.

4. What are the common defects that can occur during metal treatment and how do you prevent or correct them?

- Cracking: Prevent by avoiding rapid cooling, preheating before quenching, and using proper cooling media.

- Warping: Prevent by using uniform heating and cooling rates, fixturing to restrain movement, and minimizing thermal stresses.

- Decarburization: Prevent by using controlled atmosphere furnaces, adding carburizing agents, and protecting metal surfaces.

- Scaling: Prevent by using protective atmospheres, coatings, or controlled oxidation processes.

- Incomplete Hardening: Prevent by ensuring proper heating temperatures, cooling rates, and homogeneity of the metal.

5. How do you ensure the quality and consistency of metal treatments?

- Establish and follows standard procedures: Document processes, parameters, and quality control measures.

- Monitor and control process variables: Use sensors, gauges, and data loggers to maintain optimal conditions.

- Perform regular inspections: Visual examinations, hardness testing, and metallographic analysis to verify quality.

- Calibration and maintenance: Ensure measuring equipment and treatment systems are regularly calibrated and maintained.

- Continuous improvement: Review processes, identify areas for optimization, and implement corrective actions.

6. What is the difference between induction hardening and flame hardening and when is each process used?

- Induction Hardening:

- Uses an electromagnetic field to induce electrical currents in the metal.

- Heats the surface of the metal rapidly and precisely.

- Used for selective hardening of specific areas.

- Flame Hardening:

- Uses a flame to heat the surface of the metal.

- Heats the metal more uniformly than induction hardening.

- Used for larger areas or where precise control of the hardened depth is not required.

7. Describe the safety precautions that must be observed when performing metal treatment processes.

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and a respirator.

- Ensure proper ventilation to remove fumes and gases.

- Handle hot metals with tongs or protective gloves.

- Avoid touching heated equipment or surfaces.

- Follow established safety protocols and procedures.

8. What are the latest advancements in metal treatment technologies and how are they improving the industry?

- Laser Heat Treatment: Precise and localized heating for improved surface properties.

- Vacuum Heat Treatment: Controlled atmosphere for high-quality results and reduced oxidation.

- Plasma Nitriding: Improved wear resistance and corrosion protection.

- Additive Manufacturing: Enables complex and customized heat treatment processes.

- Computer-Aided Engineering (CAE): Simulation and modeling for optimized heat treatment parameters.

9. How do you stay up-to-date with the latest developments and best practices in metal treatment?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Participate in professional organizations.

- Consult with experts and manufacturers.

- Stay informed about new technologies and equipment.

10. What are your strengths and how do they align with the requirements of this metal treater position?

Please highlight your relevant skills and experience:

- Technical Expertise: Demonstrated understanding of metal treatment processes, heat treatment principles, and material properties.

- Quality Assurance: Experience in implementing and maintaining quality control procedures and ensuring compliance with industry standards.

- Problem Solving: Ability to diagnose and resolve issues related to metal treatment processes and equipment.

- Communication: Strong communication and interpersonal skills for interacting with customers, team members, and suppliers.

- Continuous Improvement: Passion for staying updated with industry best practices and exploring innovative solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Treaters are responsible for operating and maintaining equipment used to treat and finish metals, such as furnaces, ovens, and plating tanks. They also inspect metal products to ensure they meet quality standards.

1. Operate and maintain equipment

Metal Treaters must be able to operate and maintain various types of equipment used in metal treatment, such as furnaces, ovens, and plating tanks. They must also be able to troubleshoot and repair problems with equipment.

- Operate furnaces to heat metal to a specific temperature

- Operate ovens to cool metal after it has been heated

- Operate plating tanks to coat metal with a protective layer

- Troubleshoot and repair problems with equipment

2. Inspect metal products

Metal Treaters must be able to inspect metal products to ensure they meet quality standards. They must be able to identify defects, such as cracks, scratches, and corrosion.

- Inspect metal products for defects

- Measure metal products to ensure they meet specifications

- Record inspection results

3. Perform quality control tests

Metal Treaters must be able to perform quality control tests on metal products to ensure they meet customer requirements. They must be able to use various testing methods, such as hardness testing, tensile testing, and corrosion testing.

- Perform hardness testing to determine the hardness of metal

- Perform tensile testing to determine the strength of metal

- Perform corrosion testing to determine the resistance of metal to corrosion

4. Maintain records

Metal Treaters must be able to maintain records of their work, including inspection results, quality control test results, and equipment maintenance records.

- Maintain records of inspection results

- Maintain records of quality control test results

- Maintain records of equipment maintenance

Interview Tips

Here are some tips on how to prepare for an interview for a metal treater position:

1. Research the company

Before you go on an interview, it’s important to research the company you’re applying to. This will help you learn about the company’s culture, values, and goals. It will also help you understand the company’s specific needs and how your skills and experience can benefit the company.

- Visit the company’s website

- Read the company’s annual report

- Follow the company on social media

2. Practice answering common interview questions

There are some common interview questions that you’re likely to be asked in an interview for a metal treater position. It’s helpful to practice answering these questions in advance so that you can give clear and concise answers during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with metal treating?

- What are your career goals?

3. Be prepared to talk about your experience

In an interview, you’ll be asked to talk about your experience. Be prepared to discuss your skills and experience in metal treating, as well as your experience with operating and maintaining equipment.

- Describe your experience with operating and maintaining equipment

- Describe your experience with inspecting metal products

- Describe your experience with performing quality control tests

4. Be enthusiastic and professional

Finally, it’s important to be enthusiastic and professional during an interview. This will show the interviewer that you’re interested in the position and that you’re confident in your abilities.

- Be positive and upbeat

- Dress professionally

- Be on time for your interview

Next Step:

Now that you’re armed with the knowledge of Metal Treater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Treater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini