Are you gearing up for a career in Metal Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

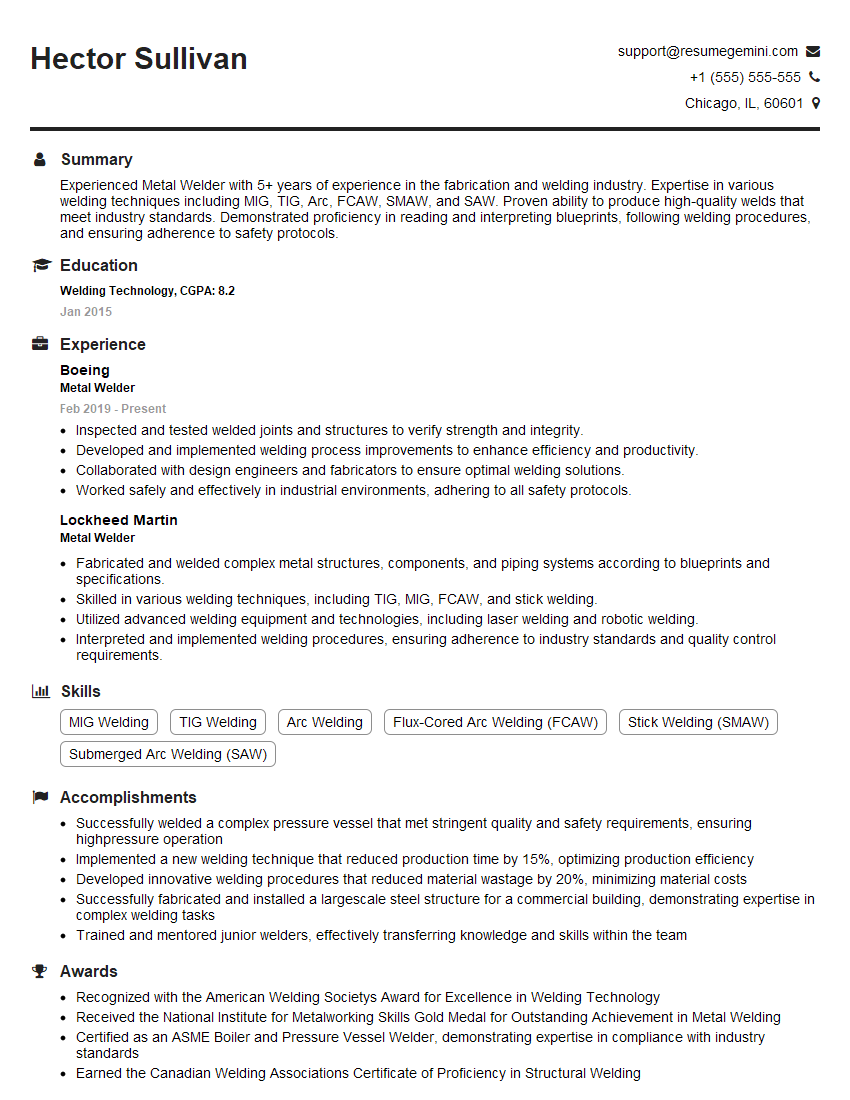

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Welder

1. What are the different types of welding processes you are familiar with?

As a seasoned welder, I have mastered a diverse range of welding processes, including:

- Arc welding: gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW)

- Resistance welding: spot welding, projection welding, and seam welding

- Solid-state welding: ultrasonic welding and friction welding

2. How do you select the appropriate welding process for a given application?

Material and Thickness:

- GTAW: suitable for thin, delicate materials like stainless steel and aluminum.

- GMAW: ideal for thicker materials, such as mild steel and shipbuilding.

- SMAW: commonly used for thicker sections and outdoor applications due to its versatility and cost-effectiveness.

Joint Type and Strength:

- Spot welding: creates strong spot welds for sheet metal applications.

- Projection welding: produces high-strength welds for automotive components.

- Seam welding: offers continuous and airtight welds for tanks and vessels.

Efficiency and Cost:

- Ultrasonic welding: efficient and ideal for delicate materials, reducing production time.

- Friction welding: cost-effective for high-volume production, providing fast and solid-state welds.

3. What are the key factors that affect the quality of a welded joint?

Ensuring the quality of welded joints requires careful consideration of the following factors:

- Proper joint preparation: Clean edges, appropriate beveling, and correct fit-up are crucial.

- Material compatibility: Understanding the welding characteristics of different metals and their compatibility is essential.

- Welding parameters: Optimizing welding parameters, such as voltage, amperage, travel speed, and shielding gas selection, is critical.

- Welding technique: Proper handling of the welding torch, maintaining a steady hand, and observing the weld pool are key.

- Post-weld processes: Heat treatment, stress relieving, and non-destructive testing ensure the structural integrity of the joint.

4. What types of non-destructive testing methods can you perform to inspect welds?

To ensure the integrity of welded joints, I am proficient in various non-destructive testing methods:

- Visual inspection: Thoroughly examining the weld surface for visual defects such as cracks, porosity, and undercut.

- Magnetic particle testing: Detecting surface and near-surface discontinuities using magnetic particles and an electromagnetic field.

- Ultrasonic testing: Utilizing sound waves to identify internal defects such as cracks, inclusions, and voids.

- Radiographic testing: Employing X-rays or gamma rays to reveal internal flaws and weld penetration.

5. How do you stay up-to-date with the latest welding technologies and best practices?

To maintain my proficiency and adapt to evolving industry standards, I actively engage in the following:

- Attending industry conferences and workshops to learn about new techniques and advancements.

- Reading technical journals and publications to stay informed about the latest research and best practices.

- Participating in online forums and discussion groups to exchange knowledge with fellow welders.

- Seeking opportunities for professional development and certification to enhance my skills.

6. What is your experience with welding in different positions?

I am highly adaptable and have extensive experience welding in various positions:

- Flat position: horizontal welding on a flat surface, providing optimal access and control.

- Horizontal position: vertical welding on a vertical surface, requiring precise hand-eye coordination.

- Overhead position: welding above head, demanding excellent spatial awareness and dexterity.

- Vertical position: welding on a vertical surface from bottom to top, ensuring proper weld penetration.

7. How do you handle working with different types of metals and alloys?

I am familiar with the unique properties of various metals and alloys and adapt my approach accordingly:

- Mild steel: Versatile and commonly used, requiring proper shielding gas to prevent oxidation.

- Stainless steel: Corrosion-resistant and challenging to weld due to its high heat conductivity.

- Aluminum: Lightweight and requires specialized welding techniques to avoid cracking.

- Exotic alloys: High-performance materials used in aerospace and medical applications, demanding precision and expertise.

8. What is your approach to welding safety?

I prioritize safety in all aspects of my work, adhering to the following practices:

- Wearing appropriate personal protective equipment, including a welding helmet, gloves, and flame-resistant clothing.

- Maintaining a clean and organized work area to minimize hazards and prevent accidents.

- Inspecting equipment regularly to ensure it is in good working order and meets safety standards.

- Following established safety protocols for handling and storing flammable materials and gases.

9. How do you manage multiple welding projects simultaneously?

To effectively manage multiple projects, I employ the following strategies:

- Prioritizing tasks based on deadlines and project criticality.

- Creating a detailed work schedule and adhering to it as closely as possible.

- Optimizing my workflow by preparing materials and setting up equipment in advance.

- Communicating regularly with supervisors and colleagues to ensure coordination and avoid delays.

10. What is your experience with welding codes and standards?

I am well-versed in industry welding codes and standards, including:

- American Welding Society (AWS) D1.1: Structural Welding Code – Steel

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- International Organization for Standardization (ISO) 3834: Quality Requirements for Welding

- I strictly adhere to these codes to ensure the quality and integrity of my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Welder is a professional who specializes in joining metal components using various welding techniques. Their primary responsibilities include:

1. Welding Operations

Execute welding operations following specified blueprints, schematics, and work orders.

- Select and use appropriate welding equipment and materials based on the type of metal and the desired joint strength.

- Prepare and clean metal surfaces to ensure proper weld adhesion.

2. Weld Inspection and Testing

Conduct visual inspections and perform non-destructive testing techniques to assess weld quality and adherence to specifications.

- Identify and correct weld defects or imperfections.

- Maintain detailed records of all welding activities and test results.

3. Equipment Maintenance

Perform routine maintenance and calibration of welding equipment to ensure optimal functionality and safety.

- Identify and troubleshoot equipment malfunctions.

- Follow safety protocols and regulations related to welding operations.

4. Safety Compliance

Observe and adhere to all safety protocols and regulations related to welding operations.

- Wear appropriate personal protective equipment (PPE) to mitigate risks.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing for a metal welder interview requires a combination of technical knowledge, practical skills, and interview strategies. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, industry standing, and specific requirements for the metal welder position.

2. Practice Welding Techniques

Brush up on your welding skills and practice different welding techniques to demonstrate your proficiency and versatility.

3. Highlight Your Safety Knowledge

Emphasize your understanding of welding safety protocols and your commitment to maintaining a safe work environment.

4. Prepare for Technical Questions

Anticipate technical questions related to welding processes, equipment, and materials. Study welding terminology and be prepared to discuss your knowledge of specific welding techniques.

5. Showcase Your Problem-Solving Abilities

Provide examples of how you have solved problems or overcome challenges related to welding operations.

6. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview demonstrates your interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!