Are you gearing up for an interview for a Metal Wire Coating Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Wire Coating Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

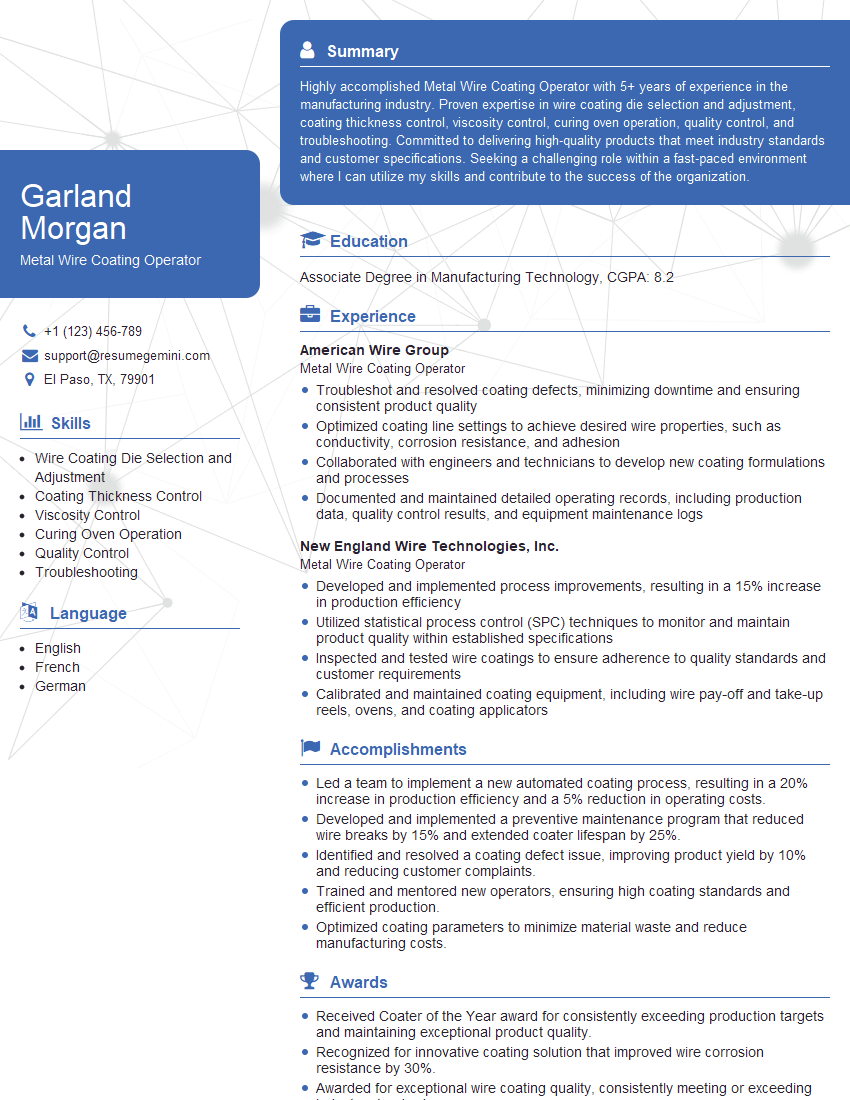

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Wire Coating Operator

1. What are the key steps involved in metal wire coating?

- Preparing the wire surface: This involves cleaning and degreasing the wire to ensure proper adhesion of the coating.

- Selecting the appropriate coating material: The choice of coating material depends on the desired properties, such as corrosion resistance or electrical conductivity.

- Applying the coating: Various techniques can be used for coating, including dipping, spraying, or electroplating.

- Curing the coating: The coated wire is subjected to heat or chemical treatment to solidify and enhance the coating’s properties.

- Testing and inspection: The coated wire is inspected and tested to ensure compliance with specifications and quality standards.

2. What factors affect the quality of a metal wire coating?

Adhesion

- Proper surface preparation

- Compatibility between the coating material and wire surface

- Curing conditions

Coating thickness

- Determined by the application method and coating material

- Affects properties such as corrosion resistance and electrical conductivity

Uniformity

- Ensures consistent coating properties throughout the wire

- Prevents defects and premature coating failure

3. What are the different types of coating defects and their causes?

- Blisters: Formation of air pockets beneath the coating, caused by improper curing or contamination.

- Cracks: Fractures in the coating, caused by excessive coating thickness, temperature stresses, or poor adhesion.

- Peeling: Separation of the coating from the wire surface, caused by poor surface preparation, insufficient curing, or incompatible coating materials.

- Pin holes: Small holes in the coating, caused by trapped air or contaminants during the coating process.

4. How do you troubleshoot common coating issues, such as poor adhesion or uneven coating thickness?

- Poor adhesion: Check surface preparation, coating compatibility, and curing conditions. Adjust as necessary.

- Uneven coating thickness: Inspect application method, coating material properties, and process parameters. Optimize settings to achieve uniform distribution.

- Identify the root cause of the issue by analyzing coating samples and reviewing process data.

- Implement corrective actions to resolve the problem and prevent recurrence.

5. What safety precautions should be taken when operating metal wire coating equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators.

- Follow established safety protocols and operating procedures.

- Handle hazardous materials with care, such as acids and solvents.

- Maintain a clean and organized work area to prevent accidents.

- Report any equipment malfunctions or unsafe conditions immediately.

6. What quality control measures are implemented to ensure the consistency and reliability of coated wire products?

- Regular monitoring of coating properties, such as thickness, adhesion, and electrical conductivity.

- Testing and inspection of finished products to meet customer specifications and industry standards.

- Implementation of statistical process control (SPC) techniques to identify and eliminate sources of variation.

- Continuous improvement initiatives to enhance product quality and process efficiency.

7. How do you stay up-to-date on the latest advances in metal wire coating technology and best practices?

- Attend industry conferences and workshops.

- Read technical journals and trade publications.

- Engage with suppliers and equipment manufacturers to learn about new developments.

- Participate in online forums and discussion groups related to metal wire coating.

8. What is your approach to working as part of a team in a metal wire coating operation?

- Effective communication and coordination with colleagues.

- Willingness to assist others and share knowledge.

- Respect for different perspectives and contributions.

- Ability to work independently and take initiative when necessary.

- Contribution to a positive and productive work environment.

9. How do you handle situations where you encounter unexpected challenges or setbacks in the metal wire coating process?

- Remain calm and assess the situation thoroughly.

- Identify the root cause of the problem using troubleshooting techniques.

- Develop and implement appropriate corrective actions.

- Seek assistance from colleagues or supervisors if necessary.

- Document the incident and lessons learned to prevent recurrence.

10. What are your long-term career goals in the metal wire coating industry?

- Advance to a supervisory or management role.

- Specialize in a particular coating technology or application.

- Contribute to the development and implementation of innovative coating solutions.

- Stay abreast of industry trends and best practices.

- Build a strong network of professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Wire Coating Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Wire Coating Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Metal Wire Coating Operator is responsible for operating wire coating machines that apply a protective layer to metal wire. Their job duties may include:

1. Machine Operation

Set up and operate wire coating machines according to specification

- Monitor machine operation and make adjustments as necessary

- Control coating thickness and uniformity

2. Product Quality Control

Inspect finished wire to ensure it meets quality standards

- Identify and correct defects

- Maintain records of coating parameters and production output

3. Maintenance and Troubleshooting

Perform routine maintenance on wire coating machines

- Troubleshoot and resolve machine malfunctions

- replace worn or damaged parts

4. Safety and Compliance

Follow all safety regulations and procedures

- Wear appropriate personal protective equipment (PPE)

- Handle chemicals and hazardous materials safely

Interview Tips

To ace an interview for a Metal Wire Coating Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry

- Review the job description thoroughly to understand the specific requirements.

- Prepare examples of your skills and experience that align with the job responsibilities.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating wire coating machines

- Discuss your experience in controlling coating thickness and uniformity.

- Showcase your knowledge of wire coating materials and processes.

3. Demonstrate Your Troubleshooting Abilities

Explain your approach to identifying and resolving machine malfunctions

- Provide specific examples of troubleshooting scenarios you have successfully handled.

- Highlight your ability to work independently and make sound decisions.

4. Emphasize Your Safety Consciousness

Stress your commitment to following safety regulations

- Describe your experience in handling chemicals and hazardous materials safely.

- Explain how you prioritize safety in your work environment.

Next Step:

Now that you’re armed with the knowledge of Metal Wire Coating Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Wire Coating Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini