Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Work Duct Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

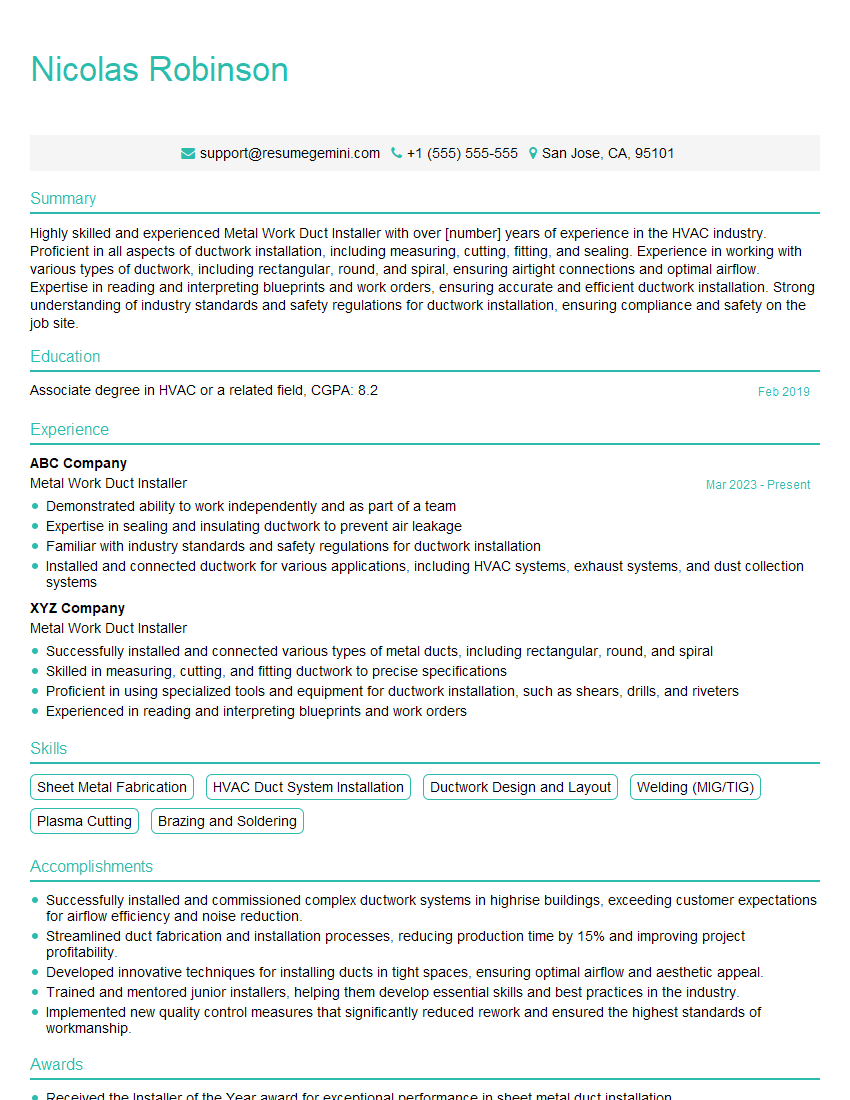

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Work Duct Installer

1. What are the different types of metal ductwork?

Various types of metal ductwork are:

- Galvanized Steel

- Stainless Steel

- Aluminum

- Fiberglass

- Flex Duct

2. What are the steps involved in installing metal ductwork?

Materials Gathering

- Gather required materials like ductwork, fittings, fasteners, and sealants.

- Ensure materials meet project specifications and building codes.

Layout and Cutting

- Determine ductwork layout based on blueprints and specifications.

- Cut ductwork to the specified lengths and shapes using appropriate tools.

Assembly and Installation

- Assemble ductwork components using fasteners and sealants.

- Secure ductwork to support structures using hangers and brackets.

Testing and Inspection

- Test ductwork for leaks and proper airflow using specialized equipment.

- Inspect the installation to ensure compliance with codes and project requirements.

3. What are the different methods used to join sheet metal ductwork?

Methods for joining sheet metal ductwork include:

- Pittsburgh Lock

- Slip Joint

- Drive Cleat

- Soldering

- Welding

4. What are the common problems encountered during metal ductwork installation, and how do you resolve them?

Common problems and their solutions during metal ductwork installation:

- Leaks: Seal leaks using sealant, tape, or gaskets.

- Improper Alignment: Realign ductwork and secure it properly.

- Vibration: Add vibration isolators or hangers to reduce noise.

- Condensation: Apply insulation or vapor barrier to prevent moisture accumulation.

- Insufficient Support: Install additional support structures to prevent sagging or collapse.

5. What safety precautions should be taken when working with metal ductwork?

- Wear appropriate PPE, including gloves, safety glasses, and a respirator.

- Handle sharp edges with care to prevent cuts.

- Use ladders and scaffolds safely when working at heights.

- Be aware of electrical hazards and follow electrical safety protocols.

- Maintain a clean work area free of tripping hazards and debris.

6. What tools and equipment are essential for metal ductwork installation?

- Sheet metal shears

- Pittsburgh lock machine

- Drill

- Screwdriver

- Wrench

- Level

- Measuring tape

- Safety glasses

- Gloves

- Respirator

7. How do you ensure the quality of your metal ductwork installations?

- Follow industry standards and building codes.

- Use high-quality materials and components.

- Employ skilled and experienced technicians.

- Conduct thorough inspections and testing.

- Obtain customer feedback and address any concerns promptly.

8. What is your experience with working with different types of metal ductwork?

I have experience working with various types of metal ductwork, including:

- Galvanized Steel

- Stainless Steel

- Aluminum

- Fiberglass

I am familiar with the properties, advantages, and disadvantages of each type of ductwork and can select the most appropriate material based on the project requirements.

9. How do you stay up-to-date with the latest advancements in metal ductwork installation techniques?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Consult with manufacturers and suppliers.

- Participate in continuing education programs.

- Network with other professionals in the field.

10. What are your strengths and weaknesses as a metal ductwork installer?

Strengths

- Skilled in various metal ductwork installation techniques.

- Strong attention to detail and accuracy.

- Excellent problem-solving and troubleshooting abilities.

- Ability to work independently and as part of a team.

- Committed to safety and quality workmanship.

Weaknesses

- Limited experience with certain specialized ductwork systems.

- Working under tight deadlines can sometimes lead to stress.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Work Duct Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Work Duct Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Metal Work Duct Installer, you will be entrusted with the crucial task of fabricating and installing metal work ducts. These ducts are essential components of heating, ventilation, and air conditioning (HVAC) systems, ensuring proper air circulation and temperature control. Your responsibilities will encompass various aspects of duct installation, from planning and layout to testing and maintenance.

1. Fabrication and Assembly

- Interpret blueprints and technical drawings to determine duct dimensions, shapes, and materials.

- Utilize specialized tools and equipment to cut, bend, and shape metal sheets into duct sections.

- Assemble duct sections using appropriate techniques, ensuring airtight and secure connections.

2. Installation and Support

- Install ductwork in residential, commercial, and industrial buildings, adhering to building codes and standards.

- Mount ducts on walls, ceilings, and floors using appropriate fasteners and support systems.

- Connect ducts to HVAC units, diffusers, and other system components.

3. Testing and Maintenance

- Conduct pressure tests to verify airtightness and ensure proper airflow.

- Inspect ducts regularly for signs of damage, leaks, or corrosion.

- Perform maintenance tasks such as cleaning ducts and replacing damaged sections.

4. Safety and Quality Assurance

- Adhere to all safety protocols and regulations related to duct installation.

- Maintain a clean and organized work area to prevent accidents.

- Ensure that all installed ducts meet specified quality standards.

Interview Tips

To ace your interview for a Metal Work Duct Installer position, preparation is key. Here are some tips to help you stand out:

1. Research the Company and Industry

- Familiarize yourself with the company’s history, services, and projects.

- Stay updated on the latest trends and advancements in the HVAC industry.

2. Practice Your Answers

- Prepare thoughtful and concise responses to common interview questions.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your skills and experiences.

3. Highlight Your Skills and Experience

- Emphasize your proficiency in metal fabrication, duct installation, and testing.

- Quantify your accomplishments whenever possible, using specific metrics.

4. Demonstrate Your Safety Awareness

- Stress your commitment to safety and your knowledge of industry standards.

- Share examples of how you have ensured a safe work environment in previous roles.

Next Step:

Now that you’re armed with the knowledge of Metal Work Duct Installer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Work Duct Installer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini