Feeling lost in a sea of interview questions? Landed that dream interview for Metal Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

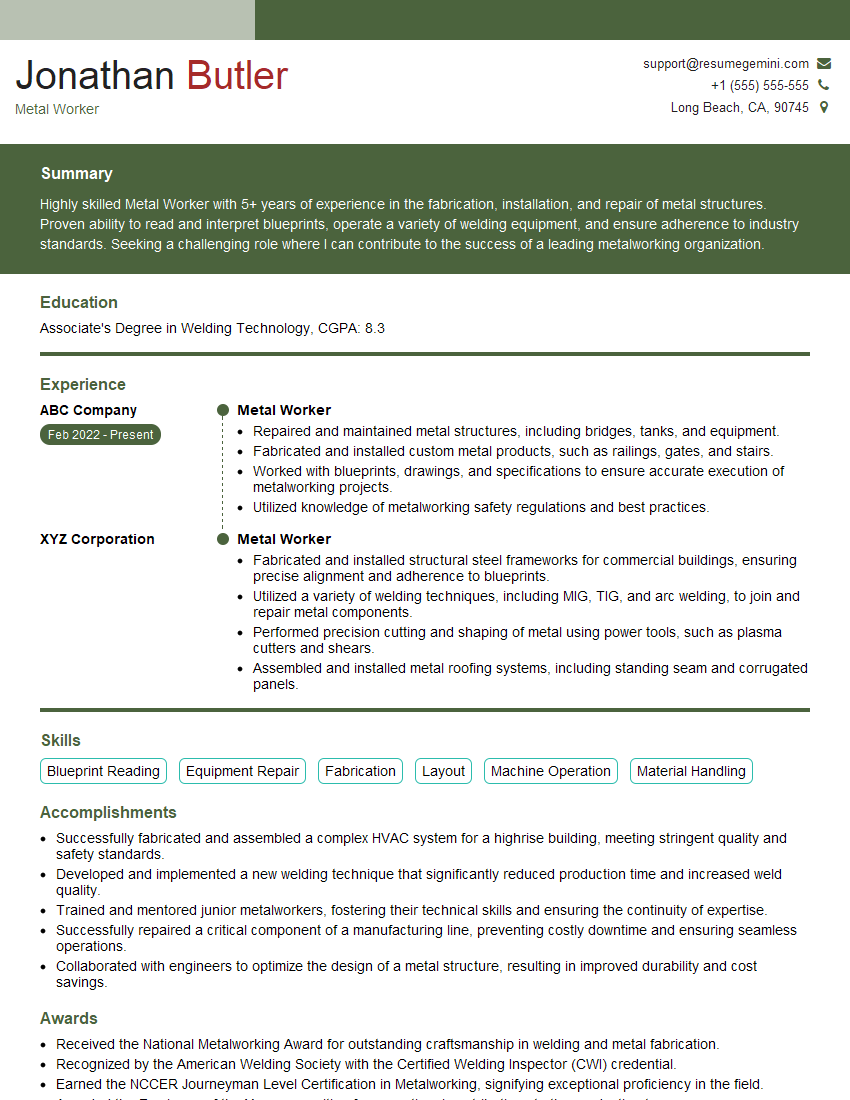

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Worker

1. Explain the different types of welding processes and when each one is typically used?

There are several types of welding processes, each with specific characteristics and applications:

- Arc Welding:

- Uses an electric arc to melt and fuse metals.

- Common types include TIG (GTAW), MIG (GMAW), and Stick (SMAW) welding.

- Gas Welding:

- Uses a flame to melt and fuse metals.

- Typically used for joining thin metals or in situations where precision is required.

- Resistance Welding:

- Generates heat through the resistance of the metal to an electric current.

- Used in high-volume manufacturing, such as joining automotive parts.

2. What are the common materials used in metalworking and how do you handle them?

Metals:

- Steel: Carbon steel (low, medium, high), stainless steel, alloy steels (chrome, nickel, etc.)

- Aluminum: Sheet aluminum, aluminum castings

- Copper: Sheet copper, copper pipes

Handling Considerations:

- Understand the properties and limitations of each material.

- Take precautions to prevent warping, deformation, or damage during handling and processing.

- Use appropriate tools and techniques for cutting, shaping, and joining different metals.

3. Describe the steps involved in creating a metal casting.

Creating a metal casting typically involves the following steps:

- Design and pattern making: Creating a model or pattern of the desired casting.

- Mold making: Preparing a mold in which molten metal is poured.

- Molten metal preparation: Melting the metal and removing impurities.

- Pouring and solidification: Pouring the molten metal into the mold and allowing it to cool and solidify.

- Removal and finishing: Removing the casting from the mold and performing any necessary finishing operations (cleaning, grinding, etc.).

4. What types of metalworking equipment are you familiar with?

I am familiar with a wide range of metalworking equipment, including:

- Welding equipment: MIG, TIG, plasma cutters, oxy-acetylene torches

- Cutting equipment: Bandsaws, circular saws, shearing machines, laser cutters

- Shaping and forming equipment: Lathes, mills, grinders, bending machines

- Inspection and testing equipment: Calipers, micrometers, hardness testers

5. What safety precautions should be observed when working with metals?

- Wear appropriate protective gear (gloves, safety glasses, flame-resistant clothing)

- Ensure proper ventilation and fume extraction

- Handle sharp objects carefully

- Avoid contact with hot surfaces

- Store and dispose of chemicals safely

6. Describe your experience in welding stainless steel.

I have extensive experience in welding stainless steel using TIG and MIG welding techniques. I understand the properties and challenges of working with stainless steel, such as its susceptibility to oxidation and heat distortion.

- TIG Welding: Used for precise and high-quality welds on thin and complex stainless steel components.

- MIG Welding: Used for higher productivity and efficiency, suitable for thicker stainless steel sections.

7. Explain how you inspect welds for defects.

I use various inspection methods to ensure the quality of my welds, including:

- Visual Inspection: Observing the weld surface for any surface defects, porosity, or cracks.

- Non-Destructive Testing (NDT):

- Radiography (X-ray or Gamma-ray): Detects internal defects and flaws.

- Ultrasonic Testing: Uses high-frequency sound waves to detect subsurface defects.

8. What is your experience in metal fabrication?

I have several years of experience in metal fabrication, including:

- Cutting and shaping: Using saws, shears, and press brakes to cut and form metal sheets.

- Welding: Joining metal components using various welding techniques.

- Assembly and fitting: Assembling and fitting metal parts together to create the final product.

9. What is the difference between hot-rolled and cold-rolled steel?

- Hot-rolled steel: Rolled at high temperatures, resulting in a rough surface finish and lower strength.

- Cold-rolled steel: Rolled at room temperature, resulting in a smoother surface finish and higher strength.

10. Describe your experience in working with alloys.

I am familiar with working with various alloys, including:

- Stainless steel alloys: For corrosion resistance and strength.

- Aluminum alloys: For lightweight and high strength.

- Tool steels: For cutting and forming tools.

I understand the different properties, heat treatment requirements, and applications of these alloys.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Workers are responsible for fabricating, assembling, and installing metal products for construction and maintenance projects. They work with a variety of metals, including steel, stainless steel, aluminum, and copper.

1. Fabricate metal components

Using blueprints and design specifications, metal workers cut, shape, and weld metal components.

2. Assemble metal structures

Metal workers assemble metal structures, such as frames, beams, and girders, using bolts, screws, and rivets.

3. Install metal products

Metal workers install metal products, such as roofing, siding, and doors, on buildings and structures.

4. Repair and maintain metal products

Metal workers repair and maintain metal products, such as fences, railings, and gates.

Interview Tips

To ace the interview for the Metal Worker position, it is important to prepare adequately. Here are some tips to help you:

1. Research the company

Before the interview, take some time to research the company. This will give you a better understanding of their business, products, and services. This information will help you answer questions about why you are interested in working for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to practice answering these questions in advance so that you can deliver your responses confidently and concisely. Some of the most common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

4. Arrive on time

Punctuality is important. Make sure that you arrive for your interview on time. It is better to arrive a few minutes early than to be late.

5. Be prepared to talk about your experience

The interviewer will likely want to know about your experience as a Metal Worker. Be prepared to talk about your skills and experience in detail. You should also be prepared to discuss any relevant projects that you have worked on.

6. Be confident

Confidence is key in any interview. Believe in yourself and your abilities. This will help you to project a positive image and make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!