Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metalizing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

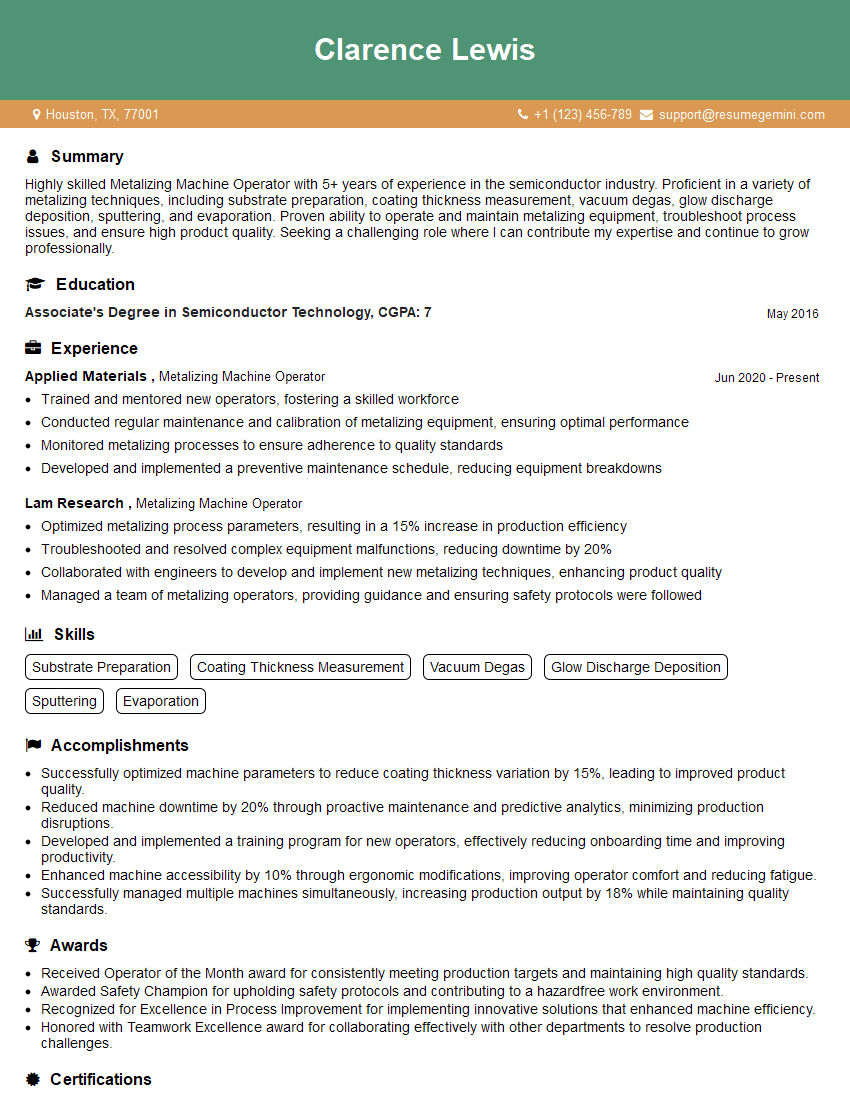

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metalizing Machine Operator

1. What are the primary responsibilities of a Metalizing Machine Operator?

- Operate and maintain metalizing machines to deposit a thin layer of metal onto various surfaces.

- Monitor and adjust machine settings to ensure optimal coating thickness, adhesion, and uniformity.

- Load and unload workpieces, prepare surfaces for metalizing, and inspect finished products.

2. How do you determine the correct coating thickness for different materials and applications?

- Substrate material and its properties.

- Desired functionality or performance of the coated surface.

- Industry standards or customer specifications.

Factors considered for determining the coating thickness:

- Magnetic induction gauges

- Eddy current gauges

- Micrometers

Methods used for measuring coating thickness:

3. Describe the different types of vacuum chambers used in metalizing and their respective advantages and disadvantages.

- Advantages: Cost-effective for small-scale production

- Disadvantages: Limited throughput, slower cycle times

- Advantages: High throughput, faster cycle times, suitable for continuous production

- Disadvantages: Higher initial investment cost, requires more maintenance

- Advantages: Produces dense, high-quality coatings, suitable for delicate substrates

- Disadvantages: Slower deposition rates, higher vacuum requirements

Batch Vacuum Chambers:

Inline Vacuum Chambers:

Sputtering Chambers:

4. Explain the process of plasma cleaning and its importance in metalizing.

- Plasma cleaning removes contaminants and activates the substrate surface, improving adhesion of the metal coating.

- It uses ionized gas to bombard the surface, breaking down organic contaminants and creating a more receptive surface for metal deposition.

- Plasma cleaning enhances coating durability, performance, and longevity.

5. Describe the role of magnetrons in sputter deposition and explain how they contribute to coating quality.

- Magnetrons are devices used in sputter deposition that enhance the ionization of the sputter gas.

- They create a magnetic field that confines electrons, increasing the probability of collision with gas atoms, resulting in higher ionization rates.

- Higher ionization rates lead to a more stable and efficient sputter process, producing uniform and high-quality coatings.

6. Explain the importance of monitoring and controlling process parameters during metalizing and how it affects coating properties.

- Process parameters such as vacuum level, gas flow rates, deposition rate, and substrate temperature influence coating characteristics.

- Monitoring and controlling these parameters ensures consistent coating thickness, adhesion, morphology, and other critical properties.

- Improper control can result in defects, poor performance, or reduced lifespan of the coated products.

7. Describe the different types of quality control tests performed on metalized surfaces and explain their significance.

- Adhesion tests assess the strength of the bond between the coating and the substrate.

- Corrosion resistance tests evaluate the coating’s ability to protect the substrate from environmental factors.

- Electrical conductivity tests measure the coating’s ability to conduct electricity, which is crucial in electronic applications.

- These tests ensure that the coating meets the required performance specifications and industry standards.

8. Explain the safety precautions that must be taken when operating metalizing machines.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a respirator.

- Ensure proper ventilation and exhaust systems to prevent exposure to hazardous gases and vapors.

- Follow established safety protocols for handling and storing flammable and toxic materials.

- Receive regular training on safe operating procedures and emergency response plans.

9. Describe a situation where you faced a technical challenge while operating a metalizing machine and how you resolved it.

- Explain the problem encountered, including any error messages or unusual observations.

- Describe the troubleshooting steps taken, using technical knowledge and diagnostic tools.

- State the solution implemented and the outcome, emphasizing how it resolved the issue.

10. How do you stay updated with the latest advancements and technologies in metalizing?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with other professionals in the field.

- Participate in training programs offered by equipment manufacturers or industry organizations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metalizing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metalizing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metalizing Machine Operators play a crucial role in the manufacturing industry, specializing in coating metal surfaces with various materials to enhance their appearance, durability, and functionality. Here are the key responsibilities associated with this role:

1. Machine Operation

Operate metalizing machines to apply a thin layer of metal to various surfaces, including plastic, glass, and metal.

- Set up and adjust machine parameters to achieve optimal coating thickness and quality.

- Monitor equipment to ensure smooth operation and troubleshoot any issues promptly.

2. Coating Material Preparation

Prepare the coating material, typically a metal powder, according to the manufacturer’s instructions.

- Load the coating material into the machine’s hopper.

- Adjust the material feed rate to ensure a uniform and consistent coating.

3. Surface Preparation

Prepare the surfaces to be coated to ensure proper adhesion of the metal layer.

- Clean and degrease the surfaces to remove any contaminants.

- Apply a primer or adhesive to enhance the coating’s bond strength.

4. Quality Control

Inspect coated surfaces to ensure they meet the specified quality standards.

- Conduct visual inspections for defects such as scratches, voids, or uneven coverage.

- Perform thickness measurements to verify adherence to specifications.

5. Maintenance

Perform routine maintenance on the metalizing machine to ensure its optimal performance.

- Clean and lubricate machine components to prevent wear and tear.

- Replace worn or damaged parts as needed.

6. Safety Compliance

Adhere to all safety protocols and guidelines to protect themselves and others in the workplace.

- Wear appropriate personal protective equipment (PPE) during operation.

- Follow established procedures for handling hazardous materials.

Interview Tips

Preparing for a Metalizing Machine Operator interview requires a comprehensive approach that encompasses both technical knowledge and soft skills. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and mission. Research the metalizing industry to understand its advancements and best practices.

2. Study the Job Description

Take the time to thoroughly review the job description to identify the key responsibilities and qualifications required for the role. Tailor your resume and interview responses to highlight your alignment with these requirements.

3. Practice Your Technical Skills

Prepare for questions related to your technical abilities in metalizing, including machine operation, coating preparation, and quality control. Consider practicing on a simulator or machine if possible.

4. Emphasize Safety Awareness

Demonstrate your understanding of safety protocols in the metalizing industry. Explain how you prioritize safety in your work and adhere to established guidelines.

5. Showcase Your Problem-Solving Abilities

Anticipate questions that explore your problem-solving capabilities. Prepare examples of situations where you encountered challenges in metalizing and describe how you resolved them effectively.

6. Highlight Your Attention to Detail

Emphasize your meticulous nature and attention to detail in your work. Explain how you ensure accuracy and precision in coating preparation, machine operation, and quality control.

7. Be Professional and Enthusiastic

Dress professionally for the interview and maintain a positive and enthusiastic attitude. Show genuine interest in the role and demonstrate your passion for the metalizing industry.

Next Step:

Now that you’re armed with the knowledge of Metalizing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metalizing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini