Feeling lost in a sea of interview questions? Landed that dream interview for Metallurgical and Quality Control Testing Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metallurgical and Quality Control Testing Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

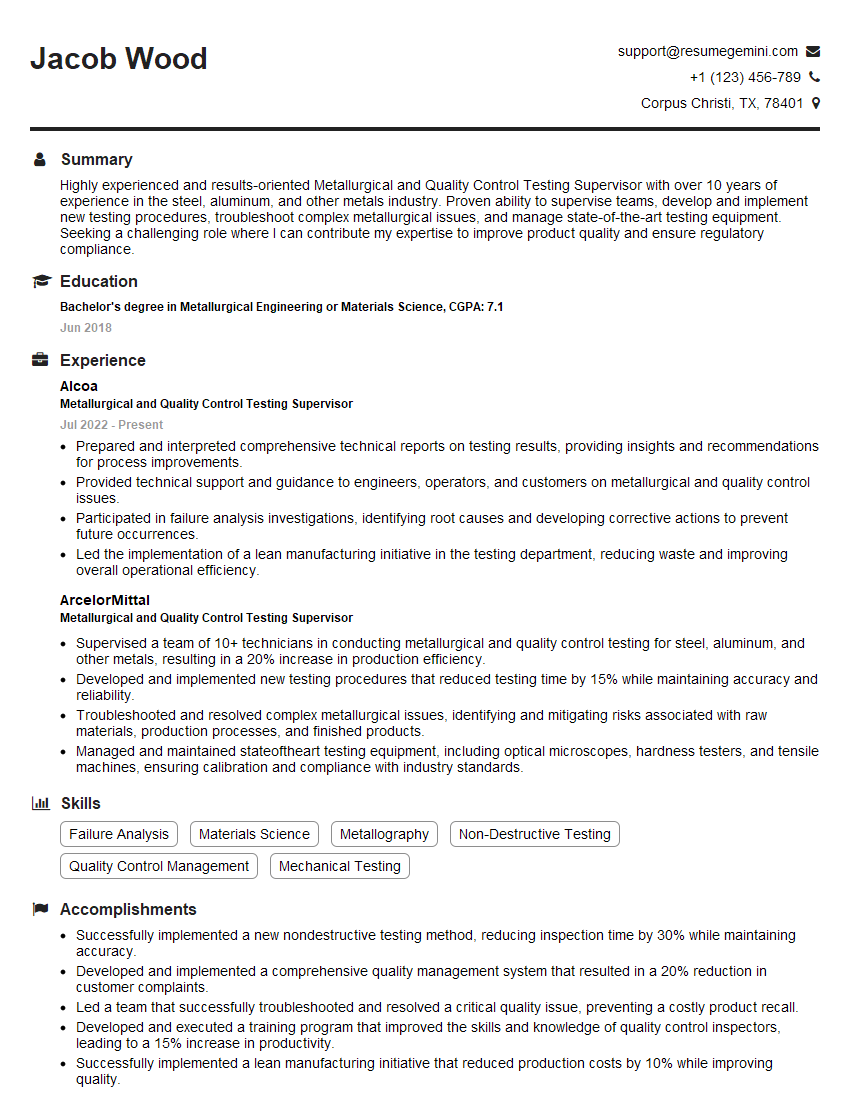

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metallurgical and Quality Control Testing Supervisor

1. Explain the principles of metallography and its applications in quality control?

Metallography is the study of the microstructure of metals. It is used in quality control to ensure that metals meet the specified requirements. The principles of metallography include:

- Sample preparation: The metal sample is prepared by cutting, grinding, and polishing to reveal the microstructure.

- Etching: The sample is etched with a chemical solution to reveal the grain boundaries and other features of the microstructure.

- Microscopy: The sample is examined under a microscope to identify the phases, grain size, and other features of the microstructure.

Metallography is used in quality control to:

- Identify the phases present in a metal.

- Determine the grain size of a metal.

- Identify defects in a metal.

- Characterize the microstructure of a metal.

2. Describe the different types of mechanical testing used in quality control and their applications?

Tensile testing

- Tensile testing is used to determine the strength and ductility of a metal.

- A tensile specimen is pulled until it breaks, and the stress-strain curve is recorded.

- The tensile strength is the maximum stress that the metal can withstand before it breaks.

- The yield strength is the stress at which the metal begins to deform plastically.

- The elongation at break is the percentage of elongation that the metal undergoes before it breaks.

Compression testing

- Compression testing is used to determine the strength and ductility of a metal under compressive loads.

- A compression specimen is compressed until it breaks, and the stress-strain curve is recorded.

- The compressive strength is the maximum stress that the metal can withstand before it breaks.

- The yield strength is the stress at which the metal begins to deform plastically.

- The elongation at break is the percentage of elongation that the metal undergoes before it breaks.

3. Explain the principles of non-destructive testing (NDT) and its applications in quality control?

Non-destructive testing (NDT) is a method of testing materials without damaging them. It is used in quality control to ensure that materials meet the specified requirements.

- Visual inspection: Visual inspection is the simplest form of NDT. It involves looking for defects on the surface of a material.

- Liquid penetrant testing: Liquid penetrant testing is used to find surface defects. A liquid penetrant is applied to the surface of the material, and then the excess penetrant is removed. Any defects will be filled with the penetrant, which can then be seen under ultraviolet light.

- Magnetic particle testing: Magnetic particle testing is used to find surface and subsurface defects. A magnetic field is applied to the material, and then magnetic particles are applied to the surface. Any defects will attract the magnetic particles, which can then be seen.

- Radiographic testing: Radiographic testing is used to find internal defects. X-rays or gamma rays are passed through the material, and the resulting image is examined for defects.

- Ultrasonic testing: Ultrasonic testing is used to find internal defects. High-frequency sound waves are passed through the material, and the resulting echoes are examined for defects.

4. Describe the different types of heat treatments used in quality control and their applications?

- Annealing: Annealing is a heat treatment process that is used to soften metals and make them more ductile.

- Normalizing: Normalizing is a heat treatment process that is used to improve the strength and toughness of metals.

- Hardening: Hardening is a heat treatment process that is used to increase the hardness and wear resistance of metals.

- Tempering: Tempering is a heat treatment process that is used to reduce the hardness and brittleness of metals.

5. Explain the principles of corrosion and how it can be prevented?

Corrosion is the deterioration of metals due to chemical reactions with the environment. It can be prevented by:

- Using corrosion-resistant materials.

- Applying protective coatings.

- Using cathodic protection.

- Controlling the environment.

6. Describe the different types of quality control systems and their applications?

- Statistical process control (SPC): SPC is a quality control system that uses statistical methods to monitor and control the quality of a process.

- Total quality management (TQM): TQM is a quality control system that focuses on continuous improvement and customer satisfaction.

- Six Sigma: Six Sigma is a quality control system that uses statistical methods to reduce defects and improve quality.

7. Explain the importance of quality control in the manufacturing industry?

Quality control is important in the manufacturing industry because it helps to ensure that products meet the specified requirements. This can help to reduce costs, improve customer satisfaction, and increase profits.

8. Describe the different types of quality management tools and their applications?

- Control charts: Control charts are used to monitor and control the quality of a process.

- Pareto charts: Pareto charts are used to identify the most common defects.

- Cause-and-effect diagrams: Cause-and-effect diagrams are used to identify the root causes of defects.

- Failure mode and effects analysis (FMEA): FMEA is a technique that is used to identify potential failures and their effects.

9. Explain the importance of teamwork in quality control?

Teamwork is important in quality control because it allows team members to share their knowledge and expertise. This can help to improve the quality of the products and processes.

10. Describe your experience in quality control?

I have over 10 years of experience in quality control. I have worked in a variety of industries, including automotive, aerospace, and medical. I have a strong understanding of quality control principles and practices. I am a certified quality control inspector and have a Six Sigma Green Belt.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metallurgical and Quality Control Testing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metallurgical and Quality Control Testing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Metallurgical and Quality Control Testing Supervisor plays a vital role in ensuring the quality and safety of materials and products. Key responsibilities include:

1. Planning and Implementing Quality Control Processes

Develop and implement comprehensive quality control plans for all aspects of metallurgical and quality control testing.

- Establish testing procedures and specifications to meet industry standards and customer requirements.

- Coordinate with production and engineering teams to ensure proper sample collection and testing.

2. Supervising and Managing Staff

Lead and motivate a team of metallurgical and quality control technicians.

- Provide technical guidance, training, and support to staff.

- Assign responsibilities and ensure timely completion of testing and reporting tasks.

3. Data Analysis and Interpretation

Analyze and interpret metallurgical and quality control test data to assess material properties and compliance.

- Utilize statistical tools and techniques to identify trends and potential issues.

- Prepare comprehensive reports and presentations to communicate findings to management and stakeholders.

4. Continuous Improvement and Troubleshooting

Continuously identify and implement improvements to quality control processes and procedures.

- Troubleshoot and resolve quality issues to ensure product integrity.

- Stay up-to-date on industry best practices and advancements in metallurgical and quality control testing.

Interview Tips

To ace the interview for the Metallurgical and Quality Control Testing Supervisor position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. Research the company’s quality control standards and any recent quality initiatives.

- Example: Study the company’s website, industry publications, and news articles.

2. Highlight Relevant Experience and Skills

Emphasize your experience in metallurgical and quality control testing, including specific techniques and equipment. Highlight your ability to analyze data, solve problems, and lead a team.

- Example: Showcase projects where you successfully implemented quality control processes or resolved quality issues.

3. Demonstrate Leadership and Teamwork

Emphasize your leadership abilities and experience in managing a team of metallurgical and quality control technicians. Describe your strategies for motivating and supporting your team.

- Example: Share an example of how you successfully coached or mentored a team member.

4. Be Prepared to Answer Technical Questions

Expect technical questions related to metallurgical testing techniques, quality control principles, and industry standards. Practice answering these questions clearly and concisely.

- Example: Prepare for questions on metallography, mechanical testing, or non-destructive testing.

5. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for your interview. Maintain a confident and enthusiastic demeanor throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Metallurgical and Quality Control Testing Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Metallurgical and Quality Control Testing Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.