Feeling lost in a sea of interview questions? Landed that dream interview for Metallurgical Engineering Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metallurgical Engineering Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

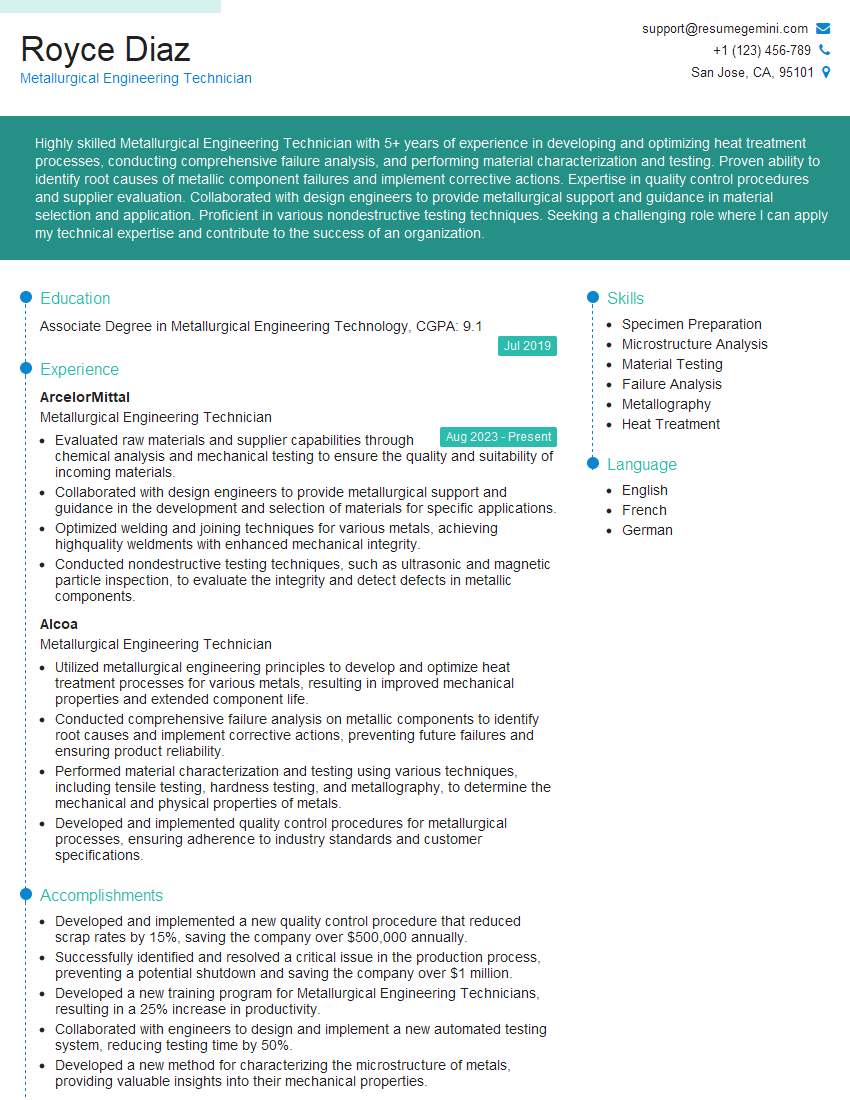

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metallurgical Engineering Technician

1. What are the different types of heat treatment processes used in metallurgy?

There are various types of heat treatment processes used in metallurgy, some of the most common include:

- Annealing: A process of heating and slowly cooling a metal to relieve internal stresses and increase ductility.

- Normalizing: A process of heating and cooling a metal in air to refine its grain structure and improve its strength and toughness.

- Hardening: A process of heating and rapidly cooling a metal to increase its hardness and wear resistance.

- Tempering: A process of heating and cooling a hardened metal to reduce its hardness and improve its toughness.

- Quenching: A process of rapidly cooling a metal in water, oil, or another medium to harden it.

2. Describe the process of metal fatigue and how it can be prevented.

Causes of Metal Fatigue

- Repeated loading and unloading of a metal

- Variations in stress levels

- Presence of defects or imperfections in the metal

Prevention of Metal Fatigue

- Using proper design techniques to minimize stress concentrations

- Selecting materials with high fatigue strength

- Applying surface treatments to improve fatigue resistance

- Regular inspection and maintenance of metal components

3. What are the different methods used for testing the mechanical properties of metals?

Common methods for testing the mechanical properties of metals include:

- Tensile testing: Measures the strength and ductility of a metal by pulling it until it breaks.

- Compression testing: Measures the strength of a metal by compressing it.

- Hardness testing: Measures the resistance of a metal to deformation.

- Impact testing: Measures the toughness of a metal by striking it with a weight.

- Fatigue testing: Measures the ability of a metal to withstand repeated loading and unloading.

4. What are the different types of corrosion and how can they be prevented?

Types of Corrosion

- Uniform corrosion: Occurs evenly over the entire surface of a metal.

- Pitting corrosion: Occurs in localized areas, forming small pits in the metal.

- Crevice corrosion: Occurs in areas where two surfaces are in close contact, such as under bolts or washers.

- Galvanic corrosion: Occurs when two dissimilar metals are in contact and one metal acts as a cathode while the other acts as an anode.

Prevention of Corrosion

- Using corrosion-resistant materials

- Applying protective coatings or paints

- Using cathodic protection

- Controlling the environment to reduce moisture and corrosive gases

5. What are the key factors to consider when selecting a material for a specific application?

Key factors to consider when selecting a material for a specific application include:

- Mechanical properties: Strength, ductility, hardness, toughness

- Physical properties: Density, thermal conductivity, electrical conductivity

- Chemical properties: Corrosion resistance, reactivity

- Environmental factors: Temperature, humidity, exposure to chemicals

- Cost and availability

6. What are the different methods used for joining metals?

Common methods for joining metals include:

- Welding: Uses heat to melt and fuse the metals together.

- Brazing: Uses a lower-melting-point metal to join the metals together.

- Soldering: Uses a low-melting-point metal to join metals with a lower melting point.

- Mechanical fastening: Uses bolts, screws, or rivets to hold the metals together.

- Adhesive bonding: Uses adhesives to bond the metals together.

7. What are the different types of non-destructive testing (NDT) methods used in metallurgy?

Common non-destructive testing (NDT) methods used in metallurgy include:

- Visual inspection: Using the naked eye or a magnifying glass to look for surface defects.

- Liquid penetrant testing: Applying a penetrant liquid to the surface and then using a developer to reveal any defects.

- Magnetic particle testing: Applying magnetic particles to the surface and then using a magnetic field to reveal any defects.

- Radiographic testing: Using X-rays or gamma rays to create an image of the internal structure of a metal.

- Ultrasonic testing: Using high-frequency sound waves to detect defects in a metal.

8. What are the different types of furnaces used in metallurgy?

Different types of furnaces used in metallurgy include:

- Arc furnaces: Use electric arcs to melt metals.

- Induction furnaces: Use electromagnetic induction to heat and melt metals.

- Blast furnaces: Use a blast of hot air to reduce iron ore to iron.

- Vacuum furnaces: Use a vacuum to remove gases from metals during heat treatment.

- Annealing furnaces: Used for annealing metals to relieve internal stresses.

9. What are the different career paths available for metallurgical engineering technicians?

Metallurgical engineering technicians can pursue careers in various industries, such as:

- Manufacturing: Working in factories that produce metal products

- Construction: Working on projects involving metal structures

- Aerospace: Working on the development and production of aircraft and spacecraft

- Automotive: Working on the development and production of automobiles

- Research and development: Working on new materials and processes

10. What is your experience with using metallurgical equipment and software?

I have experience using a variety of metallurgical equipment and software, including:

- Optical microscopes: Used to examine the microstructure of metals.

- Scanning electron microscopes (SEMs): Used to obtain high-resolution images of the surface of metals.

- X-ray diffractometers (XRDs): Used to determine the crystal structure of metals.

- Mechanical testing machines: Used to test the mechanical properties of metals.

- Metallurgical software: Used for data analysis and simulation of metallurgical processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metallurgical Engineering Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metallurgical Engineering Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metallurgical Engineering Technicians play a vital role in the metalworking industry. Their responsibilities encompass a wide range of tasks related to the testing, analysis, and production of metals and metal alloys.

1. Material Testing and Analysis

Conduct physical and chemical tests on metals and alloys to determine their properties, composition, and quality.

- Perform tensile tests, hardness tests, and corrosion tests.

- Analyze test results and prepare technical reports.

2. Metal Production and Processing

Assist in the production and processing of metals and alloys.

- Operate furnaces, casting equipment, and rolling mills.

- Monitor and control production processes to ensure quality and efficiency.

3. Technical Support

Provide technical support to engineers, metallurgists, and other professionals.

- Interpret technical drawings and specifications.

- Troubleshoot and solve production problems.

4. Quality Control

Ensure the quality of metal products.

- Inspect and test finished products.

- Identify and correct defects.

Interview Tips

Preparing for a Metallurgical Engineering Technician interview requires a combination of technical knowledge and communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s mission, values, and products. Research the specific role you are applying for and understand its key responsibilities.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Technical Skills

Demonstrate your proficiency in metallurgical testing, analysis, and production techniques. Quantify your accomplishments and provide specific examples of your work experience.

- Describe projects where you applied your knowledge of metallurgy.

- Discuss your experience with testing equipment and software.

3. Showcase Your Communication Skills

Effective communication is essential for Metallurgical Engineering Technicians. Be prepared to articulate your ideas clearly and concisely, both verbally and in writing.

- Practice answering common interview questions.

- Prepare a portfolio or presentation to showcase your technical work.

4. Prepare for Technical Questions

Expect to be asked technical questions related to metallurgy and engineering. Be familiar with the basic principles of materials science, metal processing, and quality control.

- Review your textbooks and class notes.

- Practice solving metallurgy problems.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metallurgical Engineering Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.