Are you gearing up for a career in Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

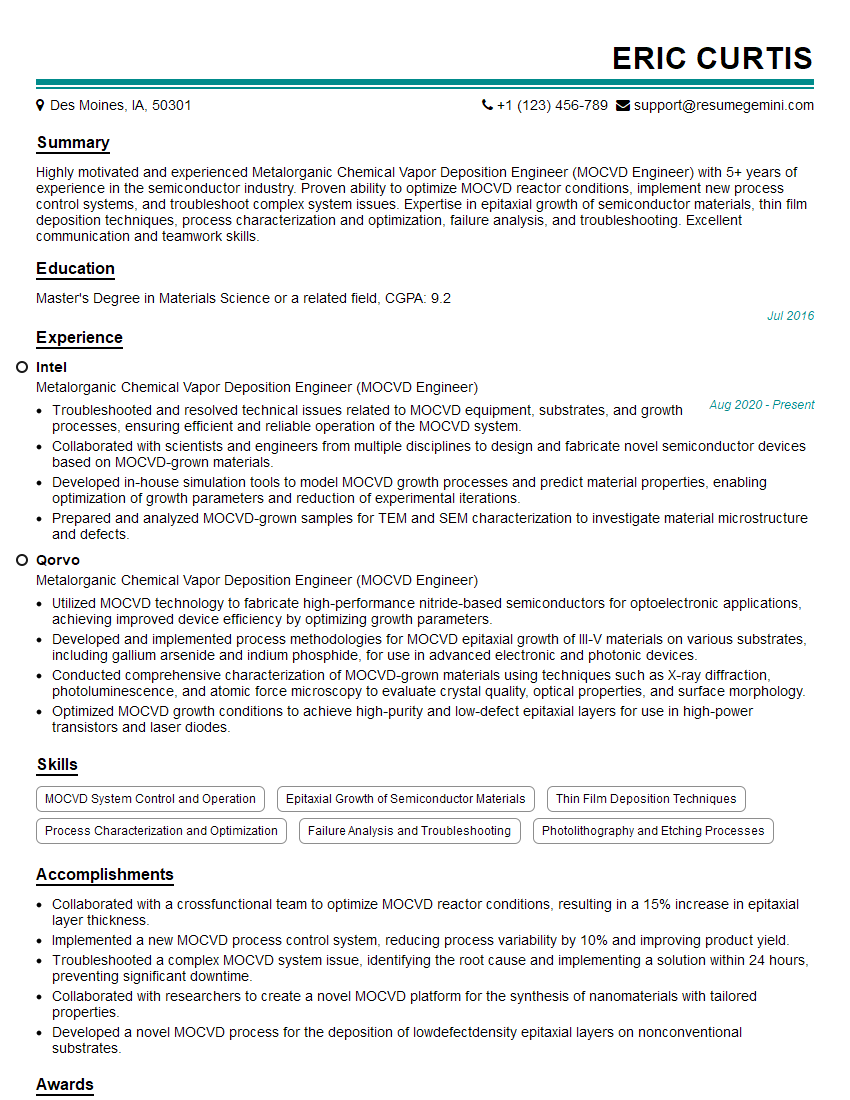

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer)

1. Explain the principle of Metalorganic Chemical Vapor Deposition (MOCVD)?

MOCVD is a chemical vapor deposition (CVD) technique used to deposit thin films of materials from organometallic precursors. The process involves the reaction of a metal-organic precursor with a reactant gas in a controlled environment. The precursor is typically a liquid or a gas that contains the metal atoms in an organic form. The reactant gas is typically a hydrogen-containing gas, such as hydrogen or ammonia. The reaction between the precursor and the reactant gas produces the desired thin film material. The deposition rate and the properties of the deposited film can be controlled by varying the temperature, pressure, and flow rate of the precursor and reactant gases.

2. Discuss the various types of MOCVD techniques?

There are two main types of MOCVD techniques: atmospheric pressure MOCVD (APMOCVD) and low-pressure MOCVD (LP-MOCVD). APMOCVD is performed at atmospheric pressure, while LP-MOCVD is performed at a reduced pressure. APMOCVD is typically used to deposit films on large-area substrates, while LP-MOCVD is used to deposit films on small-area substrates. There are also several variations of MOCVD, such as plasma-enhanced MOCVD (PE-MOCVD) and photo-enhanced MOCVD (PhE-MOCVD). These variations use different energy sources to enhance the deposition process.

3. Describe the role of precursors in MOCVD?

Precursors are the source of the metal atoms in the MOCVD process. They are typically organometallic compounds that contain the metal atoms in an organic form. The choice of precursor is important, as it can affect the deposition rate, the properties of the deposited film, and the morphology of the film. Precursors can be classified into two main types: metal-organic precursors and metal-halide precursors. Metal-organic precursors are typically more volatile than metal-halide precursors, and they can produce films with a higher purity. However, metal-halide precursors can produce films with a lower defect density.

4. Explain the importance of carrier gases in MOCVD?

Carrier gases are used to transport the precursor and reactant gases into the reaction chamber. They also help to control the flow rate and the mixing of the gases. The choice of carrier gas is important, as it can affect the deposition rate, the properties of the deposited film, and the morphology of the film. Carrier gases can be classified into two main types: inert gases and reactive gases. Inert gases, such as helium and argon, do not react with the precursor or reactant gases. Reactive gases, such as hydrogen and ammonia, can react with the precursor or reactant gases to produce additional species that can affect the deposition process.

5. Discuss the challenges associated with MOCVD?

MOCVD is a complex process that can be affected by a number of factors, such as the choice of precursor, the flow rate of the gases, the temperature of the substrate, and the pressure in the reaction chamber. These factors can affect the deposition rate, the properties of the deposited film, and the morphology of the film. It can be challenging to control the MOCVD process to produce films with the desired properties. Additionally, MOCVD can be a time-consuming and expensive process.

6. Describe the applications of MOCVD?

MOCVD is used to deposit a wide variety of materials, including metals, semiconductors, and insulators. It is used to produce thin films for a variety of applications, such as solar cells, light-emitting diodes (LEDs), and transistors. MOCVD is also used to produce coatings for a variety of applications, such as corrosion protection and wear resistance.

7. Explain the safety precautions that must be taken when working with MOCVD?

MOCVD involves the use of hazardous chemicals, such as precursors and reactant gases. It is important to take the following safety precautions when working with MOCVD:

- Wear appropriate personal protective equipment, such as gloves, a lab coat, and a respirator.

- Work in a well-ventilated area.

- Store chemicals in a safe and secure location.

- Follow all safety protocols and procedures.

8. Describe the troubleshooting techniques used to identify and resolve problems with MOCVD?

There are a number of troubleshooting techniques that can be used to identify and resolve problems with MOCVD. These techniques include:

- Checking the flow rate and pressure of the gases.

- Measuring the temperature of the substrate.

- Examining the morphology of the deposited film.

- Analyzing the composition of the deposited film.

9. Discuss the future trends in MOCVD?

MOCVD is a rapidly evolving field. Some of the future trends in MOCVD include:

- The development of new precursors and reactant gases.

- The use of new techniques to improve the deposition rate and the properties of the deposited films.

- The integration of MOCVD with other deposition techniques.

10. Describe your experience with MOCVD?

I have over 5 years of experience with MOCVD. I have worked on a variety of projects, including the deposition of thin films for solar cells, LEDs, and transistors. I am familiar with all aspects of the MOCVD process, from the selection of precursors and reactant gases to the characterization of the deposited films. I am also familiar with the safety precautions that must be taken when working with MOCVD.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer) is responsible for the operation and maintenance of MOCVD equipment used in the production of semiconductor devices. Key job responsibilities include:

1. Equipment Operation

Operate and maintain MOCVD equipment, including the loading and unloading of wafers, the control of process parameters, and the monitoring of equipment performance.

- Follow established operating procedures to ensure the proper functioning of MOCVD equipment.

- Monitor and adjust process parameters to optimize the quality of the deposited films.

2. Process Development

Develop and improve MOCVD processes to meet the requirements of new device designs. This involves:

- Experimenting with different process parameters to determine their effects on the properties of the deposited films.

- Collaborating with other engineers to develop new process technologies.

3. Troubleshooting

Troubleshoot and resolve problems with MOCVD equipment and processes. This involves:

- Identifying the root cause of problems using diagnostic techniques and data analysis.

- Implementing corrective actions to resolve problems and prevent their recurrence.

4. Quality Control

Monitor the quality of the deposited films and ensure that they meet the specifications of the device design. This involves:

- Performing electrical, optical, and physical characterization of the deposited films.

- Identifying and correcting any deviations from the specifications.

Interview Tips

To ace an interview for a MOCVD Engineer position, it is important to be well-prepared and to demonstrate your knowledge and skills in the following areas:

1. Technical Knowledge

Be familiar with the principles of MOCVD and the different types of MOCVD equipment. You should also have a strong understanding of the process parameters that affect the properties of the deposited films.

- Review the basics of MOCVD, including the different types of precursors, carrier gases, and reactors.

- Research the specific MOCVD equipment that is used by the company you are interviewing with.

2. Experience

Highlight your experience in operating and maintaining MOCVD equipment. If you have experience in process development or troubleshooting, be sure to mention that as well.

- Quantify your experience by providing specific examples of projects you have worked on.

- Be prepared to discuss your role in troubleshooting and resolving problems with MOCVD equipment and processes.

3. Problem-Solving Skills

MOCVD Engineers need to be able to solve problems quickly and efficiently. Be prepared to provide examples of how you have solved problems in the past.

- Describe a specific problem that you encountered and how you went about solving it.

- Explain the steps you took to identify the root cause of the problem and the actions you took to resolve it.

4. Communication Skills

MOCVD Engineers need to be able to communicate effectively with other engineers, technicians, and management. Be prepared to answer questions about your communication skills and to provide examples of how you have communicated technical information in the past.

- Highlight your ability to communicate complex technical information in a clear and concise manner.

- Provide examples of presentations or reports that you have given on MOCVD-related topics.

5. Continuous Improvement

MOCVD Engineers need to be committed to continuous improvement. Be prepared to discuss your plans for staying up-to-date on the latest MOCVD technologies and for improving your skills.

- Describe your experience in attending conferences or workshops on MOCVD.

- Explain how you stay up-to-date on the latest MOCVD research and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metalorganic Chemical Vapor Deposition Engineer (MOCVD Engineer) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.