Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metalsmith Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metalsmith Helper so you can tailor your answers to impress potential employers.

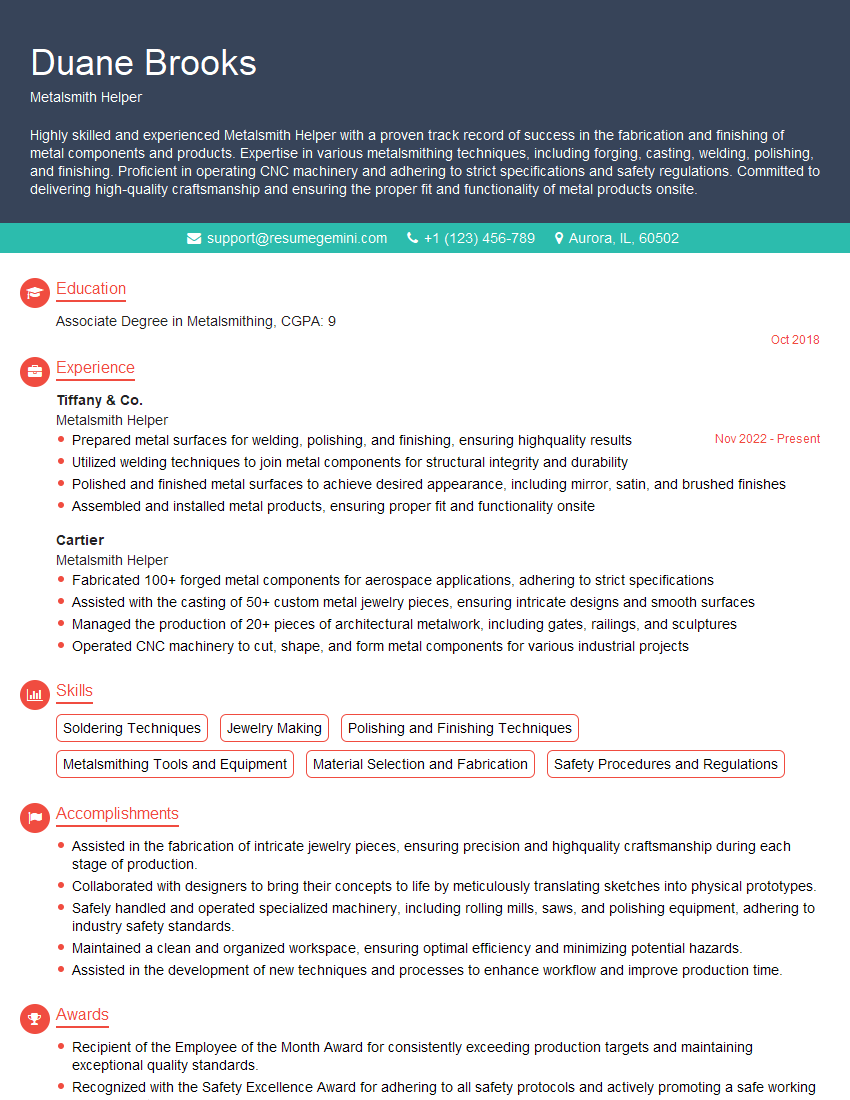

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metalsmith Helper

1. What are the different types of metals used in jewelry making and their properties?

- Gold: Gold is a precious metal that is soft and malleable, making it easy to work with. It is often alloyed with other metals to increase its strength and durability.

- Silver: Silver is another precious metal that is slightly harder than gold. It is also malleable and ductile, making it easy to shape and form.

- Platinum: Platinum is a dense, white metal that is very hard and durable. It is often used in jewelry because it is hypoallergenic and does not tarnish.

- Palladium: Palladium is a silver-white metal that is similar to platinum in terms of its hardness and durability. It is also hypoallergenic and does not tarnish.

- Copper: Copper is a reddish-brown metal that is relatively soft and ductile. It is often used in jewelry for its color and because it is a good conductor of heat and electricity.

2. What are the different types of jewelry making techniques and their advantages and disadvantages?

Wire wrapping

- Advantages: Wire wrapping is a relatively simple and inexpensive technique that can be used to create a wide variety of jewelry styles.

- Disadvantages: Wire wrapping can be time-consuming, and it can be difficult to achieve precise results.

Beading

- Advantages: Beading is a versatile technique that can be used to create a wide variety of jewelry styles, from simple to complex.

- Disadvantages: Beading can be time-consuming, and it can be difficult to find the right beads for a specific design.

Metalsmithing

- Advantages: Metalsmithing is a versatile technique that can be used to create a wide variety of jewelry styles, from simple to complex.

- Disadvantages: Metalsmithing requires specialized tools and equipment, and it can be difficult to learn the techniques.

3. What are the different types of tools used in metalsmithing and their functions?

- Anvil: A heavy block of metal that is used as a support for hammering and forming metal.

- Bench pin: A small, flat block of metal that is used to hold metal while it is being worked.

- Burnisher: A smooth, rounded tool that is used to polish and harden metal.

- Chasing hammer: A small, round-headed hammer that is used to create designs in metal.

- Divider: A tool that is used to measure and mark metal.

- File: A tool that is used to cut and shape metal.

- Forge: A device that is used to heat metal to a high temperature.

- Mandrel: A round, tapered tool that is used to shape metal.

- Pliers: A tool that is used to hold and manipulate metal.

- Saw: A tool that is used to cut metal.

- Soldering iron: A tool that is used to join metal pieces together.

- Tweezers: A tool that is used to hold small pieces of metal.

4. What are the different types of finishes that can be applied to metal jewelry and their effects?

- Polished: A smooth, shiny finish that is achieved by buffing the metal with a fine abrasive.

- Satin: A smooth, matte finish that is achieved by sandblasting the metal with a fine abrasive.

- Oxidized: A dark, blackened finish that is achieved by exposing the metal to a chemical solution.

- Patina: A green or blueish finish that is achieved by exposing the metal to the elements.

- Brushed: A finish that is achieved by brushing the metal with a wire brush.

- Antiqued: A finish that is achieved by applying a chemical solution to the metal that creates a darkened, aged look.

5. What safety precautions should be taken when working with metals?

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Keep flammable materials away from heat sources.

- Dispose of chemicals properly.

- Be aware of the hazards of the materials you are working with.

6. How do you troubleshoot common problems that can occur when working with metals?

Here are some common problems that can occur when working with metals, and some troubleshooting tips:

- Metal is too hard to work with: Anneal the metal by heating it to a high temperature and then cooling it slowly.

- Metal is too soft: Work-harden the metal by hammering or rolling it.

- Metal is tarnishing: Clean the metal with a mild detergent and water, and then apply a protective coating.

- Solder is not flowing properly: Clean the metal surfaces to be soldered, and use the correct type of solder and flux.

7. What are the career opportunities for a metalsmith helper?

- Jewelry maker

- Metalsmith

- Blacksmith

- Sculptor

- Teacher

8. What are the educational and training requirements for a metalsmith helper?

- High school diploma or equivalent

- Vocational training in metalsmithing

- Apprenticeship under a Master Metalsmith

9. What are the qualities of a successful metalsmith helper?

- Dexterity

- Patience

- Creativity

- Attention to detail

- Good communication skills

10. What are the benefits of working as a metalsmith helper?

- Job satisfaction

- Creative outlet

- Opportunities for advancement

- Competitive salary

- Benefits package

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metalsmith Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metalsmith Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Metalsmith Helper is responsible for performing a variety of tasks to assist the Metalsmith in the fabrication of metal products. This includes setting up and operating machinery, performing quality control checks on finished products, maintaining a clean and safe work area, and performing other related duties as assigned.

1. Setup and Operate Machinery

The Metalsmith Helper is responsible for setting up and operating the following machinery:

- Power saws

- Drills

- Grinders

- Welding equipment

- Shearing equipment

The Metalsmith Helper must be able to safely operate these machines and follow all safety protocols.

2. Perform Quality Control Checks

The Metalsmith Helper is responsible for performing quality control checks on finished products to ensure that they meet specifications.

- Inspecting products for defects

- Measuring products to ensure that they are within tolerance

- Testing products to ensure that they meet performance requirements

The Metalsmith Helper must be able to identify defects and measure products accurately.

3. Maintain a Clean and Safe Work Area

The Metalsmith Helper is responsible for maintaining a clean and safe work area. This includes:

- Cleaning machinery and work surfaces

- Keeping the work area free of debris

- Ensuring that all tools and equipment are in good working order

The Metalsmith Helper must be able to work in a clean and safe environment.

4. Perform Other Related Duties

The Metalsmith Helper may also be required to perform other related duties, such as:

- Assisting the Metalsmith with the fabrication of metal products

- Running errands

- Cleaning up the work area

The Metalsmith Helper must be able to perform these duties in a timely and efficient manner.

Interview Tips

In order to ace your interview for a Metalsmith Helper position, it is important to prepare in advance. Here are a few tips to help you make a good impression and increase your chances of getting the job:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience, so be prepared to talk about your qualifications in detail.

4. Dress Professionally and Arrive on Time

It is important to make a good first impression, so dress professionally for your interview and arrive on time. This will show the interviewer that you are serious about the job and that you respect their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metalsmith Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.