Feeling lost in a sea of interview questions? Landed that dream interview for Methane Capturing System Maintenance Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Methane Capturing System Maintenance Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

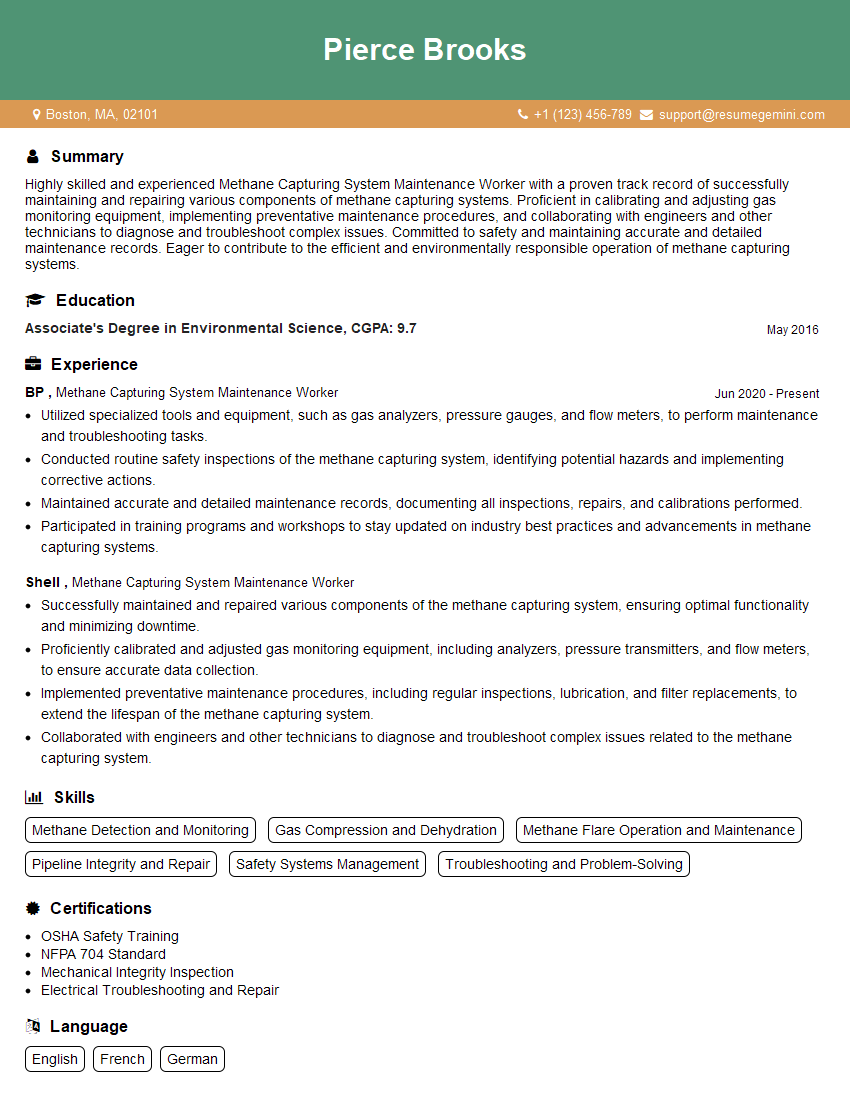

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Methane Capturing System Maintenance Worker

1. Explain the different types of methane capturing systems you have worked with and their respective maintenance requirements?

During my career, I have encountered various types of methane capturing systems including:

- Biogas Digesters: Responsible for maintaining and inspecting gas storage tanks, piping systems, biogas flares, and other crucial components. Regular cleaning, leak detection, and performance monitoring are essential.

- Landfill Gas Collection Systems: Extensive experience in servicing gas extraction wells, pipelines, condensate traps, and flare systems. Ensured optimal methane capture by monitoring system performance and conducting regular maintenance.

- Coal Mine Methane Capture Systems: Familiar with the upkeep of degasification boreholes, surface collection networks, and methane utilization or flaring facilities. Prioritized safety procedures and adhered to stringent ventilation requirements.

2. Describe the key safety protocols and regulations you adhere to when working on a methane capturing system?

Complying with Industry Standards

- Thoroughly follow established safety procedures outlined by OSHA, EPA, and other regulatory bodies.

- Wear appropriate personal protective equipment (PPE) including respirators, flame-resistant coveralls, and safety glasses.

Hazard Identification and Control

- Conduct thorough risk assessments to identify potential hazards associated with methane capturing systems.

- Implement control measures to mitigate risks, such as gas monitoring, ventilation systems, and emergency response plans.

Training and Communication

- Regularly participate in safety training programs to stay updated on best practices and regulations.

- Communicate safety concerns and observations to supervisors and colleagues promptly.

3. How do you troubleshoot and diagnose common issues in a methane capturing system?

My approach to troubleshooting and diagnosing common issues in a methane capturing system involves the following steps:

- Gather Information: Collect data from monitoring systems, inspect equipment, and interview operators to gather a comprehensive understanding of the issue.

- Analyze Data: Examine sensor readings, maintenance records, and historical data to identify patterns and potential root causes.

- Isolating the Issue: Conduct tests and experiments to pinpoint the specific component or subsystem responsible for the problem.

- Develop a Solution: Based on the diagnosis, determine the appropriate corrective actions, considering safety, efficiency, and cost-effectiveness.

4. What are the preventive maintenance tasks you perform to ensure optimal performance of a methane capturing system?

To maintain optimal performance of a methane capturing system, I conduct a comprehensive range of preventive maintenance tasks, including:

- Regular Inspections: Conduct routine visual inspections of all system components, including gas flares, pipelines, and control systems, to identify potential issues early on.

- Equipment Calibration and Testing: Calibrate and test sensors, monitors, and safety devices to ensure accurate readings and reliable operation.

- System Cleaning and Maintenance: Clean and maintain pipelines, filters, and other system components to prevent blockages and ensure efficient gas flow.

- Lubrication and Adjustments: Lubricate moving parts and make necessary adjustments to maintain optimal equipment performance.

5. How do you stay updated with the latest advancements and best practices in methane capturing technology?

To remain knowledgeable and up-to-date with the latest advancements and best practices in methane capturing technology, I actively engage in the following activities:

- Industry Conferences and Events: Attend industry conferences and workshops to learn about new technologies and research findings.

- Technical Publications: Subscribe to industry publications and journals to stay informed about technical innovations and best practices.

- Online Courses and Webinars: Participate in online courses and webinars offered by industry experts to enhance my knowledge and skills.

- Networking: Connect with other professionals in the field through professional organizations and online forums to exchange ideas and share best practices.

6. Describe a situation where you successfully identified and resolved a complex issue in a methane capturing system.

In a previous role, I encountered a complex issue involving a malfunctioning biogas flare at a landfill gas collection system. The flare had been experiencing intermittent failures, leading to the release of unburned methane into the atmosphere.

- Troubleshooting and Diagnosis: I conducted a thorough investigation, including reviewing maintenance logs, inspecting the flare system, and analyzing data from monitoring devices.

- Root Cause Analysis: After careful analysis, I identified a faulty ignition system as the root cause of the problem. The spark plugs had become fouled and were no longer generating a strong enough spark to ignite the methane.

- Solution and Implementation: I replaced the faulty spark plugs with new ones, ensuring proper ignition and combustion. This resolved the issue and restored the flare’s optimal operability.

7. How do you prioritize your workload and manage multiple tasks effectively in a fast-paced environment?

In a fast-paced environment, I prioritize my workload and manage multiple tasks effectively using the following strategies:

- Task Prioritization: I assess the urgency and importance of each task and prioritize them accordingly, focusing on critical tasks first.

- Time Management Techniques: I utilize time management techniques such as the Eisenhower Matrix and Pomodoro Technique to allocate my time wisely and minimize distractions.

- Delegation and Collaboration: When necessary, I delegate tasks to qualified colleagues and collaborate with others to ensure timely completion of all responsibilities.

8. How do you ensure your maintenance activities comply with environmental regulations and safety standards?

To ensure compliance with environmental regulations and safety standards, I adhere to the following practices:

- Regulatory Knowledge: I stay informed about relevant environmental regulations and safety standards and ensure my maintenance activities comply with them.

- Environmental Best Practices: I incorporate environmental best practices into my maintenance routine, such as minimizing waste and using eco-friendly materials.

- Safety Protocols: I strictly follow all safety protocols and procedures, including wearing appropriate PPE and conducting thorough risk assessments before starting any maintenance work.

9. How do you handle situations where you need to make quick decisions under pressure?

In situations where I need to make quick decisions under pressure, I follow these steps:

- Assess the Situation: I take a moment to assess the situation, identify the most critical factors, and gather necessary information.

- Consider Options: I evaluate different options and their potential outcomes, considering the risks and benefits of each.

- Make a Decision: Based on my assessment and evaluation, I make a decision and take prompt action, communicating my rationale clearly to others involved.

10. How do you manage your professional development and stay up-to-date with the latest tools and technologies in the field?

To manage my professional development and stay up-to-date with the latest tools and technologies in the field, I engage in the following activities:

- Continuous Learning: I actively seek opportunities to expand my knowledge and skills through workshops, conferences, and online courses.

- Industry Research: I conduct research on emerging trends and technological advancements in the methane capturing industry.

- Network with Experts: I connect with professionals in the field to exchange ideas and learn from their experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Methane Capturing System Maintenance Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Methane Capturing System Maintenance Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Methane Capturing System Maintenance Workers play a vital role in ensuring that methane capturing systems run efficiently and effectively. Their responsibilities encompass a range of essential tasks, such as:

1. System Monitoring and Inspection

Regularly monitor and inspect all components of the methane capturing system, including pipelines, compressors, valves, and sensors.

- Check for leaks, blockages, or any signs of wear and tear.

- Use specialized equipment, such as methane detectors and pressure gauges, to verify system performance.

2. Maintenance and Repair

Perform scheduled maintenance and repairs to keep the system in optimal operating condition.

- Lubricate moving parts, replace filters, and adjust components as needed.

- Troubleshoot and resolve minor technical issues to minimize downtime.

3. Emergency Response

Respond promptly to any emergencies or system failures that may occur.

- Isolate affected areas, stop gas flow, and initiate emergency shutdown procedures.

- Work with other team members to resolve issues and restore system operation.

4. Record Keeping and Reporting

Maintain detailed records of all maintenance activities, repairs, and system performance.

- Prepare reports on system status, maintenance schedules, and any incidents.

- Document findings and recommendations for system improvements.

Interview Tips

To ace the interview for a Methane Capturing System Maintenance Worker position, candidates should prepare thoroughly and highlight their relevant skills and experience. Here are some essential tips:

1. Research the Company and Role

Take the time to research the company and the specific role you are applying for. This will help you understand the company’s mission, values, and the scope of responsibilities involved in the position.

- Visit the company’s website and read about their business operations and commitment to sustainability.

- Review the job description carefully and identify the key skills and qualifications required.

2. Highlight Relevant Experience

Emphasize your relevant experience and skills that align with the job requirements. Focus on your knowledge of methane capturing systems, maintenance procedures, and emergency response protocols.

- Provide specific examples of your involvement in system maintenance, troubleshooting, and repair.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact on system uptime and efficiency.

3. Demonstrate Safety Awareness

Safety is of paramount importance in this role. Highlight your understanding of safety regulations and your commitment to following proper procedures.

- Describe your experience with hazardous materials handling and emergency response drills.

- Emphasize your ability to work safely and effectively in a potentially hazardous environment.

4. Prepare for Technical Questions

Be prepared to answer technical questions about methane capturing systems, maintenance techniques, and troubleshooting procedures. Review the basics of methane capture technology and demonstrate your understanding of system components.

- Practice answering common technical questions such as: “Explain the operation of a methane compressor” or “How would you troubleshoot a gas leak in the system?”

- Consider bringing examples of your technical knowledge and problem-solving abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Methane Capturing System Maintenance Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!