Are you gearing up for an interview for a Mica Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mica Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

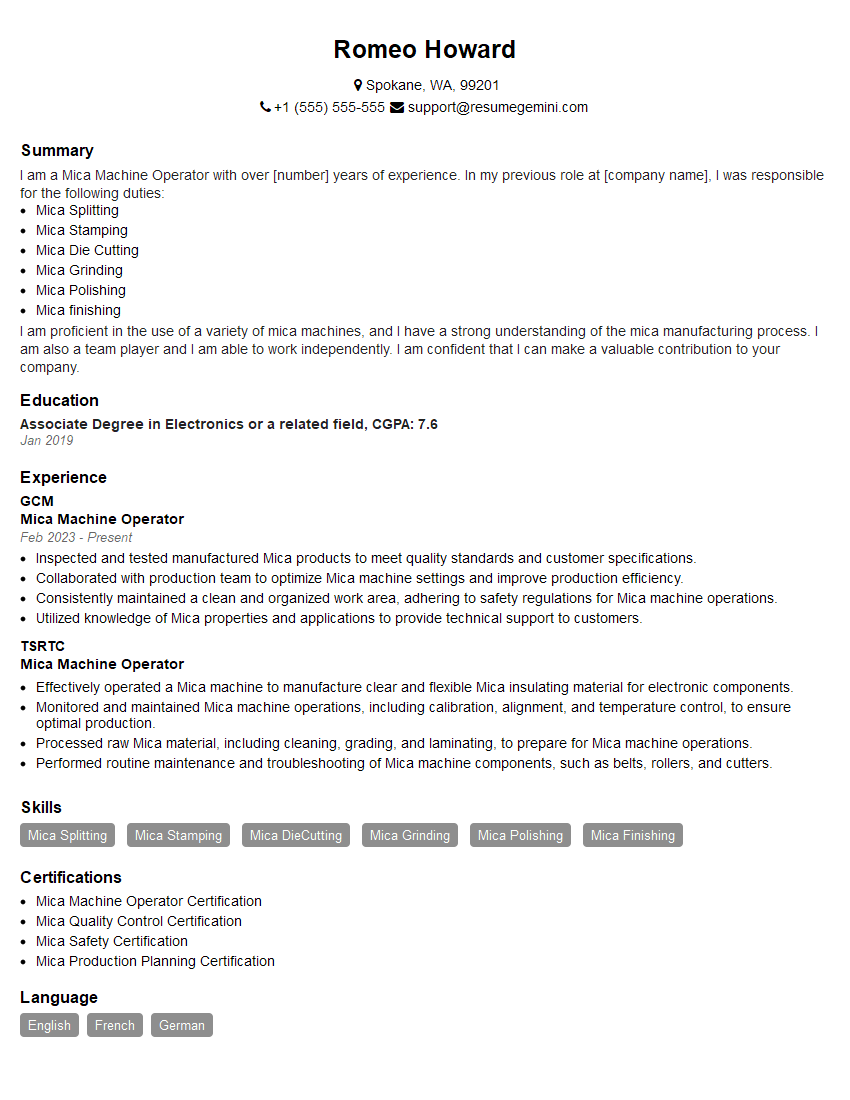

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mica Machine Operator

1. Describe the key responsibilities of a Mica Machine Operator?

- Operate and monitor mica splitting and punching machines to cut and shape mica sheets.

- Set up and adjust machine parameters, such as speed, blade angle, and pressure, to optimize production.

- Inspect finished mica sheets for quality and accuracy, ensuring they meet specifications.

- Maintain a clean and safe work environment by following safety protocols and regularly servicing equipment.

- Troubleshoot and resolve any operational issues or machine malfunctions promptly.

2. Can you explain the process of mica splitting and punching?

Splitting

- Loading mica blocks into the splitting machine.

- Adjusting blade angle and pressure to achieve desired thickness.

- Operating the machine to split mica into thin sheets.

Punching

- Loading mica sheets into the punching machine.

- Setting up punch dies and aligning sheets.

- Operating the machine to cut mica into desired shapes and sizes.

3. What are the quality standards and specifications for mica sheets?

- Thickness tolerance within specified range.

- Smooth and flat surface with minimal imperfections.

- Free from cracks, inclusions, or discoloration.

- Precise shape and size according to customer specifications.

4. How do you ensure the accuracy of mica sheet dimensions?

- Calibrating the splitting and punching machines regularly.

- Using precision measuring instruments, such as micrometers or calipers.

- Conducting regular inspections to detect any deviations from specifications.

- Adjusting machine parameters as needed to maintain accuracy.

5. What is the importance of maintaining a clean work environment in a mica processing facility?

- Reduces the risk of contamination and defects in mica sheets.

- Prevents dust and debris from entering machines and causing malfunctions.

- Ensures a safe and healthy workplace for employees.

6. Describe your experience in troubleshooting mica machine malfunctions?

Mention specific examples and explain the steps taken to identify and resolve the issues.

7. How do you stay updated on the latest mica processing techniques and best practices?

- Attending industry workshops and conferences.

- Reading technical articles and publications.

- Seeking guidance from experienced supervisors or colleagues.

8. What are your strengths and weaknesses as a Mica Machine Operator?

Strengths

- Expertise in operating mica splitting and punching machines.

- Strong attention to detail and quality control.

- Excellent troubleshooting and problem-solving skills.

- Ability to work independently and as part of a team.

- Commitment to safety and maintaining a clean work environment.

Weaknesses

- Limited experience with advanced mica processing techniques.

- Working extended hours or overtime can sometimes be challenging.

9. Why are you interested in this Mica Machine Operator position?

Express enthusiasm for the role and the company, and highlight how your skills and experience align with the job requirements.

10. Do you have any questions for me about the position or the company?

Asking thoughtful questions demonstrates your interest and engagement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mica Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mica Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mica Machine Operators are responsible for operating machines that process mica, a type of mineral used in various industries. They ensure that the machines are operating efficiently and safely, and that the mica is processed according to specifications.

1. Machine Operation

Key responsibilities include operating mica processing machines, such as cutting, grinding, and polishing machines. They must be able to set up and adjust the machines, as well as monitor their operation to ensure that the mica is processed to the correct specifications.

- Set up and operate mica processing machines, such as cutting, grinding, and polishing machines

- Adjust machine settings to ensure that the mica is processed to the correct specifications

- Monitor machine operation to ensure that the mica is processed safely and efficiently

2. Material Handling

Mica Machine Operators are also responsible for handling the mica before and after processing. They must be able to move heavy loads of mica, and they must also be able to store and retrieve mica from storage areas.

- Load and unload mica from processing machines

- Move heavy loads of mica

- Store and retrieve mica from storage areas

3. Quality Control

Mica Machine Operators must be able to inspect the mica to ensure that it meets the required specifications. They must also be able to identify and correct any defects in the mica.

- Inspect mica to ensure that it meets the required specifications

- Identify and correct any defects in the mica

- Maintain records of mica processing and quality control

4. Safety

Mica Machine Operators must follow all safety procedures when operating machines and handling mica. They must also be able to identify and avoid potential hazards in the workplace.

- Follow all safety procedures when operating machines and handling mica

- Identify and avoid potential hazards in the workplace

- Use personal protective equipment, such as gloves, safety glasses, and earplugs

Interview Tips

Preparing for an interview can help you make a good impression and increase your chances of getting the job. Here are some tips to help you ace your Mica Machine Operator interview:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand the company’s culture, values, and products or services. You can also use this information to tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the company’s social media pages

- Talk to people who work at the company

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Use the STAR method to answer interview questions

- Practice answering questions about your experience, skills, and qualifications

- Practice answering questions about your strengths and weaknesses

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual clothing, such as jeans or T-shirts.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing casual clothing, such as jeans or T-shirts

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route ahead of time and allow extra time for traffic

- If you are running late, call or email the interviewer to let them know

- Do not arrive more than 15 minutes early for your interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mica Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!