Are you gearing up for an interview for a Microelectronics Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Microelectronics Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

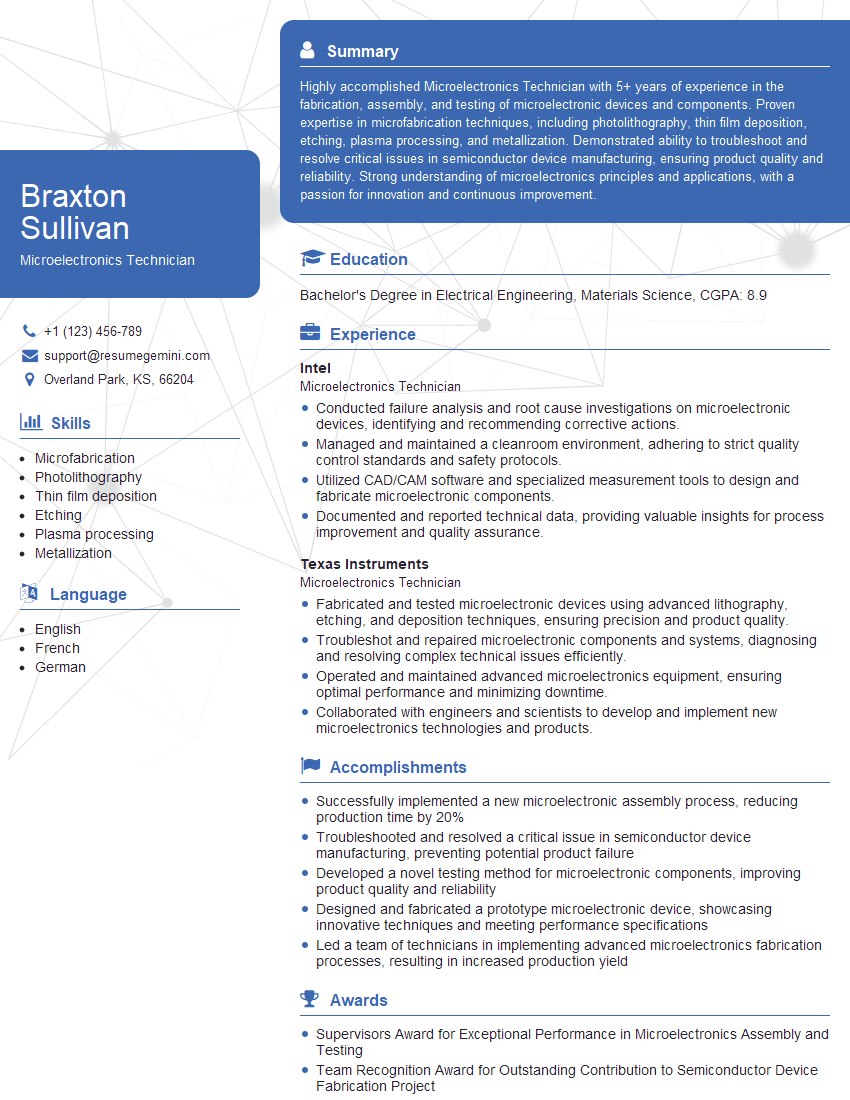

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Microelectronics Technician

1. What are the different types of microelectronics fabrication processes?

Microelectronics fabrication involves various processes, including:

- Wafer preparation: Cleaning, etching, and preparing the silicon wafer for processing.

- Lithography: Transferring circuit patterns onto the wafer using photoresist and light or electron beams.

- Thin film deposition: Adding layers of materials onto the wafer using techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD).

- Etching: Removing specific areas of deposited materials to create circuit features.

- Doping: Introducing impurities into the semiconductor to modify its electrical properties.

- Metallization: Depositing metal layers to form interconnects, contacts, and electrodes.

- Packaging: Enclosing the fabricated circuits in protective materials and connecting them to external components.

2. Describe the steps involved in photolithography.

Pre-baking

- Heating the photoresist to remove solvents and improve adhesion.

Exposure

- Exposing the photoresist to a light source (UV or X-ray) through a mask containing the circuit pattern.

Post-exposure bake

- Heating the photoresist again to initiate chemical reactions and harden the exposed areas.

Development

- Soaking the photoresist in a developer solution that dissolves the unexposed areas.

Hardening

- Heating the developed photoresist to complete the chemical reactions and improve its resistance to etching.

3. What are the different types of etching techniques used in microelectronics fabrication?

Etching techniques include:

- Wet etching: Using liquid etchants to dissolve the exposed areas of the substrate.

- Dry etching: Using plasma or reactive ions to remove material through physical or chemical reactions.

- Anisotropic etching: Etching that proceeds in a direction perpendicular to the substrate surface.

- Isotropic etching: Etching that proceeds in all directions, resulting in undercut structures.

- Reactive ion etching (RIE): Using reactive ions in a plasma to etch specific materials while protecting others.

4. Explain the process of ion implantation in microelectronics fabrication.

Ion implantation involves:

- Accelerating ions of a desired dopant into the semiconductor wafer.

- Implanting the ions at a specific energy and dose to control their penetration depth and concentration.

- Creating localized regions of altered electrical properties by introducing impurities into the semiconductor.

5. Describe the role of lithography in integrated circuit (IC) manufacturing.

Lithography in IC manufacturing plays a crucial role by:

- Circuit patterning: Transferring circuit designs onto the semiconductor wafer using photoresist and light or electron beams.

- Mask making: Creating high-resolution masks that contain the circuit patterns.

- Mask alignment: Aligning the masks precisely with the wafer during exposure to ensure accurate pattern transfer.

- Enabling device scaling: Allowing for the fabrication of increasingly smaller and denser ICs by reducing feature sizes through advanced lithography techniques.

6. Explain the different methods of thin film deposition used in microelectronics.

Thin film deposition methods include:

- Chemical vapor deposition (CVD): Reacting gaseous precursors to form solid films on the substrate.

- Physical vapor deposition (PVD): Evaporating or sputtering atoms or molecules from a source material onto the substrate.

- Molecular beam epitaxy (MBE): Growing single-crystal films layer by layer under ultra-high vacuum conditions.

- Atomic layer deposition (ALD): Depositing thin films in a controlled manner by alternating precursor exposures and purging steps.

7. Discuss the importance of cleanroom environments in microelectronics fabrication.

Cleanrooms are essential in microelectronics fabrication because they:

- Control contamination: Minimize the presence of dust, particles, and other contaminants that can affect device performance.

- Maintain temperature and humidity: Ensure optimal conditions for processing and prevent electrostatic discharge (ESD).

- Protect equipment: Shield sensitive equipment from external contaminants and environmental factors.

- Enhance product yield: Reduce defects and improve the quality and reliability of fabricated devices.

- Comply with industry standards: Meet strict requirements for cleanliness and contamination control.

8. Describe the testing procedures involved in microelectronics fabrication.

Testing procedures in microelectronics fabrication include:

- Wafer probing: Testing individual die on the wafer before packaging.

- Package testing: Verifying the functionality and performance of packaged devices.

- Reliability testing: Assessing device stability and durability under various environmental conditions.

- Failure analysis: Investigating defective devices to identify root causes and improve fabrication processes.

9. Explain the significance of metrology in microelectronics fabrication.

Metrology in microelectronics fabrication involves:

- Dimensional measurements: Determining the physical dimensions of features on the wafer.

- Electrical measurements: Assessing device properties such as resistance, capacitance, and current-voltage characteristics.

- Material characterization: Analyzing the composition and properties of materials used in the fabrication process.

- Process control: Monitoring and adjusting fabrication processes to ensure product quality.

- Yield improvement: Identifying and addressing defects to increase device yield.

10. Discuss the emerging trends in microelectronics fabrication technologies.

Emerging trends in microelectronics fabrication include:

- 3D integration: Stacking multiple layers of devices to increase functionality and reduce size.

- Advanced lithography techniques: Using extreme ultraviolet (EUV) and nano-imprinting lithography for finer feature sizes.

- Novel materials and devices: Exploring new materials like graphene and 2D semiconductors for improved performance and energy efficiency.

- Flexible and stretchable electronics: Developing flexible and deformable devices for wearable and implantable applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Microelectronics Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Microelectronics Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Microelectronics Technicians play a vital role in the design, development, and testing of electronic devices and systems. Their responsibilities encompass a wide range of tasks, including:

1. Fabrication and Assembly

Involves constructing and assembling microelectronic components and devices using specialized equipment.

- Fabricating semiconductor devices and integrated circuits (ICs) through processes such as photolithography, etching, and thin-film deposition.

- Assembling ICs into electronic modules and systems, ensuring proper connections and functionality.

2. Testing and Troubleshooting

Ensuring the quality and reliability of microelectronic products is key.

- Conducting electrical, functional, and environmental testing on microelectronic devices and systems.

- Troubleshooting and repairing defective devices, identifying and resolving issues at the component level.

3. Material Analysis and Process Development

Microelectronics Technicians often contribute to research and development initiatives.

- Analyzing materials used in microelectronic devices, identifying their properties and potential applications.

- Developing new processes and techniques to improve the performance and reliability of microelectronic products.

4. Technical Support and Documentation

Providing technical support and documentation is important for customer satisfaction.

- Providing technical support to customers, answering questions and resolving issues related to microelectronic products.

- Creating and maintaining technical documentation, such as datasheets, user manuals, and training materials.

Interview Tips

Preparing thoroughly for a Microelectronics Technician interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s mission, values, and products. Research the specific role you’re applying for, understanding its responsibilities and requirements.

- Visit the company’s website and social media pages to learn about their culture and recent developments.

- Read industry publications and articles to stay up-to-date on the latest advancements in microelectronics.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in microelectronics fabrication, testing, and troubleshooting. Provide specific examples of your work that demonstrate your proficiency.

- Quantify your accomplishments whenever possible, using metrics to showcase the impact of your contributions.

- Be prepared to discuss your knowledge of microelectronic materials, processes, and equipment.

3. Demonstrate Your Analytical and Problem-Solving Abilities

Microelectronics Technicians need to be able to analyze problems, identify root causes, and develop solutions. Share examples of how you have successfully solved technical challenges in the past.

- Describe a specific project where you used your analytical skills to troubleshoot and resolve a complex issue.

- Explain how you approach problem-solving, emphasizing your logical and methodical approach.

4. Emphasize Your Teamwork and Communication Skills

Microelectronics Technicians often work as part of a team, so it’s important to demonstrate your ability to collaborate effectively. Highlight your communication skills and experience in working with engineers, technicians, and customers.

- Share examples of how you have successfully worked with others to achieve project goals.

- Describe your experience in presenting technical information to audiences with varying levels of understanding.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Microelectronics Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.