Are you gearing up for a career in Microsystems Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Microsystems Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

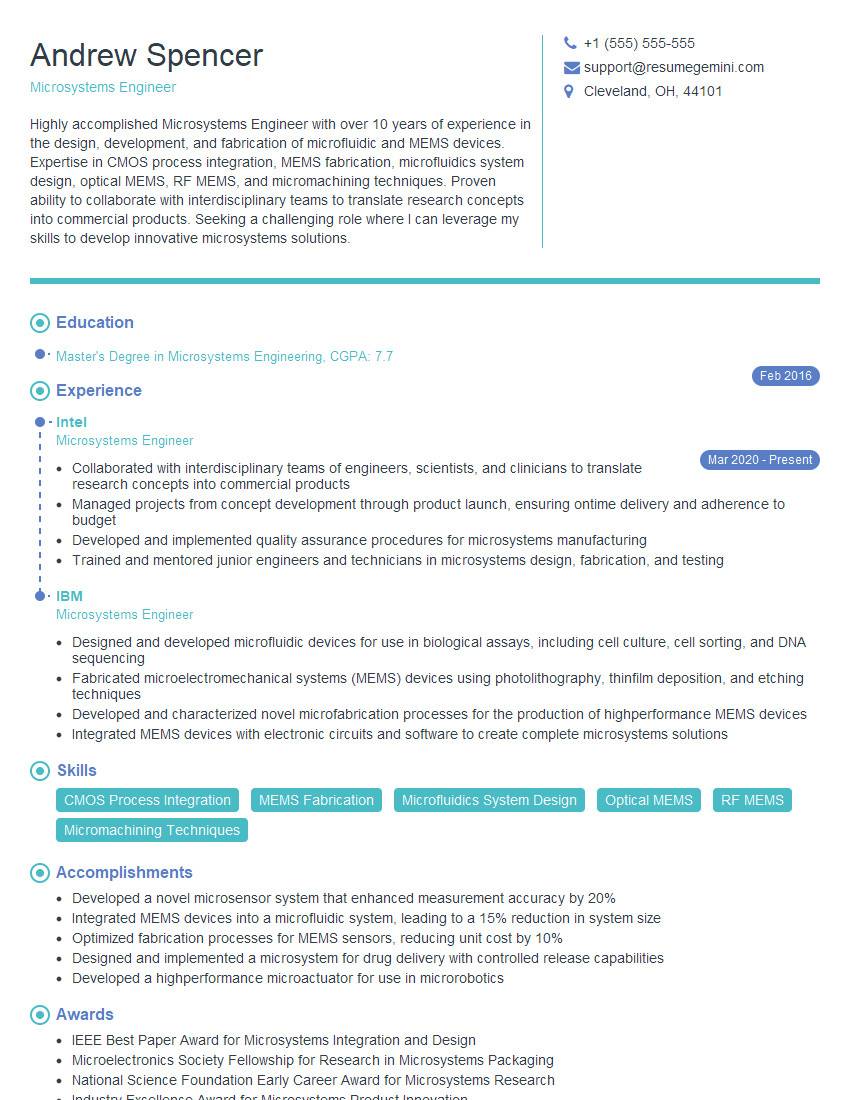

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Microsystems Engineer

1. What are the key differences between MEMS (Micro-electromechanical systems) and NEMS (Nano-electromechanical systems)?

- Size and scale: MEMS devices are typically larger than NEMS devices, ranging from microns to millimeters in size. NEMS devices, on the other hand, can be as small as nanometers in size.

- Materials: MEMS devices are often made from traditional materials, while NEMS devices are more likely to be made from advanced materials, such as carbon nanotubes or graphene.

- Manufacturing methods: MEMS devices are typically manufactured using conventional techniques, while NEMS devices require more specialized fabrication techniques.

- Applications: MEMS devices are used in a wide range of applications, including sensors, actuators, and displays. NEMS devices are still in their early stages of development, but they have the potential to revolutionize many fields, such as medicine, energy, and transportation.

2. What are the different types of MEMS and NEMS devices?

MEMS devices

- Sensors: MEMS sensors are used to measure physical parameters, such as acceleration, pressure, and temperature.

- Actuators: MEMS actuators are used to control physical movement, such as in valves and pumps.

- Displays: MEMS displays are used to display information, such as in electronic watches and cell phones.

NEMS devices

- Nanotubes: Carbon nanotubes are one-dimensional structures with remarkable electrical and mechanical properties.

- Nanowires: Nanowires are one-dimensional structures that are typically made from semiconductors.

- Quantum dots: Quantum dots are zero-dimensional structures that have unique optical and electronic properties.

3. What are the advantages and disadvantages of MEMS and NEMS devices?

MEMS devices

Advantages:- Low cost: MEMS devices can be mass-produced at a low cost.

- Small size: MEMS devices are small and lightweight, which makes them suitable for use in a wide range of applications.

- High performance: MEMS devices can achieve high performance levels, such as high sensitivity and low power consumption.

- Limited functionality: MEMS devices are typically limited to a single function.

- Reliability concerns: MEMS devices can be fragile and susceptible to failure.

NEMS devices

Advantages:- Increased functionality: NEMS devices can be integrated with other devices to create complex systems.

- Improved performance: NEMS devices can achieve even higher performance levels than MEMS devices.

- New possibilities: NEMS devices have the potential to create new possibilities, such as the development of ultra-sensitive sensors and ultra-efficient energy sources.

- High cost: NEMS devices are still expensive to manufacture.

- Complexity: NEMS devices are complex to design and fabricate.

- Reliability challenges: NEMS devices are still facing reliability challenges.

4. What are the challenges in designing and fabricating MEMS and NEMS devices?

- Materials: MEMS and NEMS devices are often made from advanced materials, which can be difficult to work with.

- Fabrication techniques: MEMS and NEMS devices require specialized fabrication techniques, which can be expensive and time-consuming.

- Packaging: MEMS and NEMS devices are often small and fragile, which makes them difficult to package.

- Testing: MEMS and NEMS devices can be difficult to test, as they are often small and complex.

5. What are the applications of MEMS and NEMS devices?

- MEMS devices: MEMS devices are used in a wide range of applications, including sensors, actuators, displays, and medical devices.

- NEMS devices: NEMS devices are still in their early stages of development, but they have the potential to revolutionize many fields, such as medicine, energy, and transportation.

6. What are the future trends in MEMS and NEMS technology?

- Integration: MEMS and NEMS devices are becoming increasingly integrated with other technologies, such as electronics and photonics.

- Miniaturization: MEMS and NEMS devices are becoming smaller and smaller, which is opening up new possibilities for applications.

- New materials: New materials are being developed for MEMS and NEMS devices, which is improving their performance and reliability.

- Advanced fabrication techniques: New fabrication techniques are being developed for MEMS and NEMS devices, which is reducing their cost and complexity.

7. What is your experience with MEMS and NEMS technology?

I have been working with MEMS and NEMS technology for the past 5 years. I have experience in designing, fabricating, and testing MEMS and NEMS devices. I have also worked on developing new materials and fabrication techniques for MEMS and NEMS devices.

8. What are your strengths and weaknesses as a MEMS and NEMS engineer?

Strengths

- Strong technical skills: I have a strong understanding of MEMS and NEMS technology. I am also proficient in a variety of design, fabrication, and testing techniques.

- Creative and innovative: I am always looking for new ways to improve MEMS and NEMS technology. I am also open to new ideas and challenges.

- Team player: I am a team player and I am always willing to help others. I am also able to work independently and take initiative.

Weaknesses

- Limited experience in some areas: I have not had much experience in some areas of MEMS and NEMS technology, such as packaging and testing.

- Can be too detail-oriented: I can sometimes be too detail-oriented, which can slow down my progress.

9. What are your salary expectations?

My salary expectations are in line with the market rate for MEMS and NEMS engineers with my experience and skills. I am also open to discussing a salary range that is commensurate with the responsibilities of the position.

10. Do you have any questions for me?

- What are the company’s goals for MEMS and NEMS technology?

- What are the company’s current projects in MEMS and NEMS technology?

- What are the company’s plans for future development of MEMS and NEMS technology?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Microsystems Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Microsystems Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Microsystems Engineers leverage their comprehensive knowledge of microfabrication techniques, semiconductor physics, and mechanical engineering to design, develop, and test micro-devices and systems. Their responsibilities encompass a wide range of tasks, including:

1. Design and Development

Conceptualizing and designing microsystems, incorporating innovative solutions and optimizing performance.

- Selecting and integrating materials, sensors, actuators, and electronics into micro-device designs.

- Using computer-aided design (CAD) software to create detailed models and simulations of microsystems.

2. Fabrication and Integration

Collaborating with fabrication teams to produce microsystems using microfabrication techniques.

- Monitoring and controlling fabrication processes to ensure quality and accuracy.

- Integrating micro-devices and systems with larger systems, ensuring seamless functionality.

3. Testing and Characterization

Conducting rigorous testing and evaluation of microsystems to assess performance and reliability.

- Developing test protocols and methodologies to evaluate electrical, mechanical, and optical properties.

- Analyzing test results and providing feedback for design improvements and optimizations.

4. Troubleshooting and Problem Solving

Identifying and resolving technical issues that arise during design, fabrication, or testing.

- Analyzing system failures, conducting root cause analysis, and implementing corrective actions.

- Collaborating with cross-functional teams to address complex challenges and find innovative solutions.

Interview Tips

Preparing thoroughly for a Microsystems Engineer interview is crucial. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Study the job description and identify the key requirements and responsibilities.

- Visit the company website, read industry news, and connect with employees on LinkedIn to gain insights.

- Tailor your resume and cover letter to highlight skills and experience that align with the position.

2. Brush Up on Technical Knowledge

Microsystems engineering is a highly technical field. Ensure you have a solid understanding of the fundamentals and latest advancements.

- Review core concepts in microfabrication, microfluidics, MEMS, and semiconductor physics.

- Familiarize yourself with industry-standard design tools and simulation software.

3. Practice Your Communication Skills

Communicating technical concepts clearly and effectively is essential. Practice answering common interview questions and prepare examples that showcase your problem-solving abilities.

- Explain complex technical concepts in a concise and engaging manner.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your teamwork, problem-solving, and conflict resolution skills.

- Think about past experiences that demonstrate your collaboration, adaptability, and attention to detail.

- Use the STAR method to provide structured answers that highlight your strengths and accomplishments.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Microsystems Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.