Are you gearing up for a career in Mig-Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mig-Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

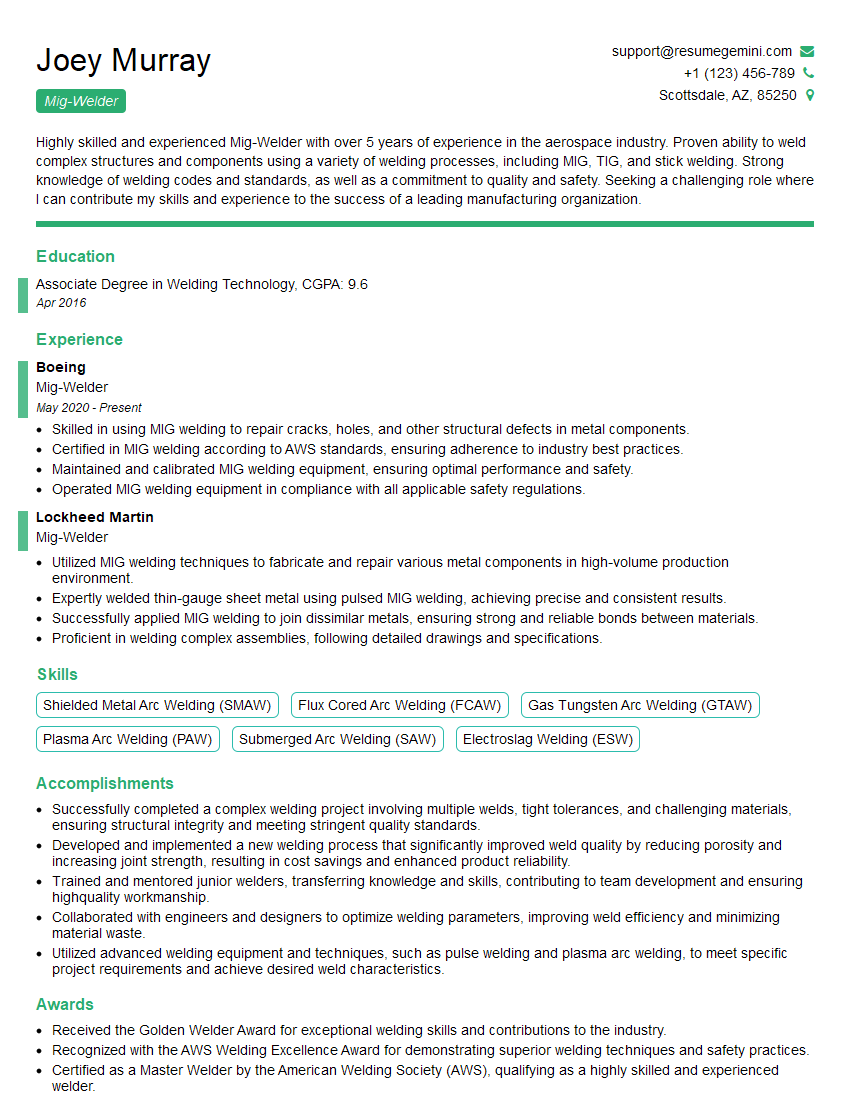

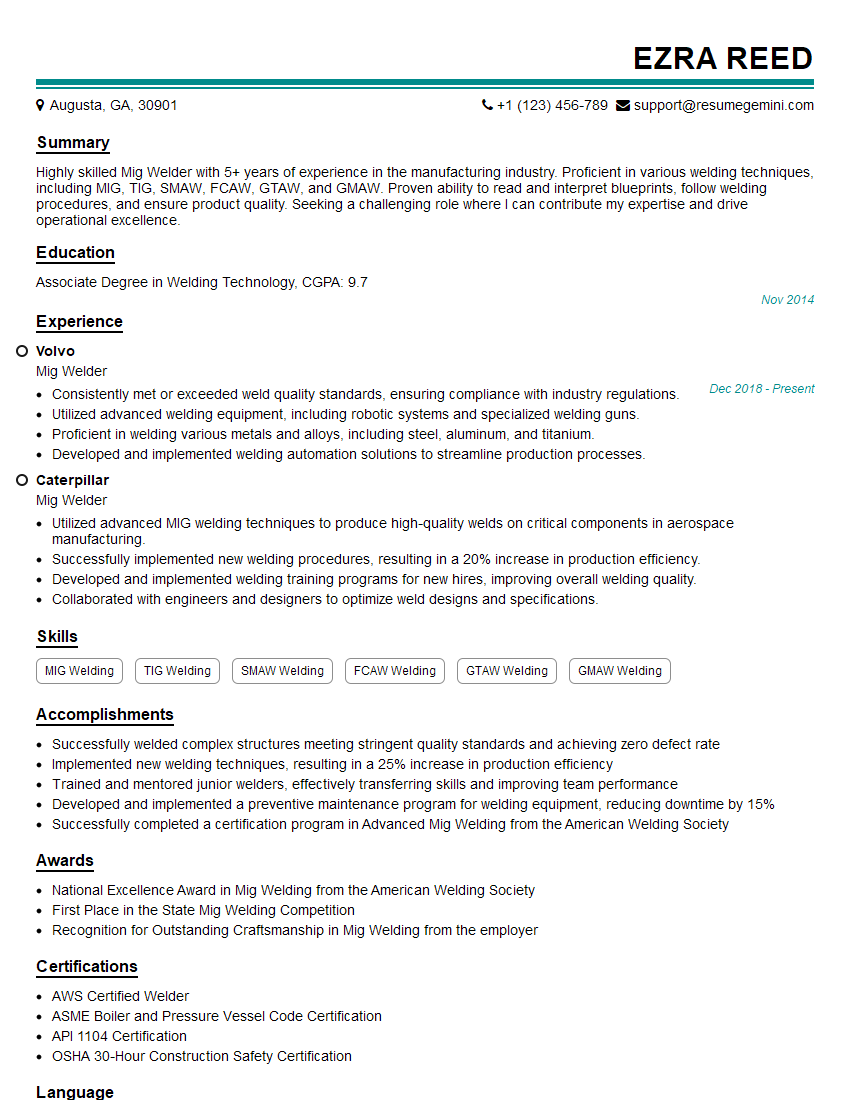

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mig-Welder

1. What are the different types of MIG welding processes and their applications?

- GMAW (Gas Metal Arc Welding): Uses an inert gas (e.g., argon or helium) to shield the weld pool.

- FCAW (Flux-Cored Arc Welding): Uses a tubular wire filled with flux that melts and generates a protective gas shield.

- MCAW (Metal-Cored Arc Welding): Similar to FCAW, but the flux is contained within the core of the wire.

- GTAW (Gas Tungsten Arc Welding): A non-consumable tungsten electrode is used to create an arc, and a separate shielding gas is used to protect the weld pool.

2. Explain the role of shielding gas in MIG welding.

- Protects the weld pool from oxygen and nitrogen: Prevents oxidation and embrittlement.

- Stabilizes the arc: Acts as an insulator between the electrode and the workpiece.

- Influences the weld bead shape and penetration: Different gases can produce different results.

3. How do you determine the correct shielding gas flow rate for MIG welding?

- Material thickness and weld penetration: Thicker materials require higher flow rates.

- Welding position: Out-of-position welding requires higher flow rates to prevent gas loss.

- Wind conditions: Windy conditions necessitate increased flow rates to maintain gas coverage.

4. Describe the different types of welding joints used in MIG welding.

- Butt joint: Two pieces of metal are joined edge-to-edge.

- T-joint: One piece of metal is perpendicular to another.

- Lap joint: Two pieces of metal overlap.

- Edge joint: Two pieces of metal are joined by welding their edges together.

5. What are the common welding defects in MIG welding and their causes?

- Porosity: Gas bubbles trapped in the weld due to insufficient gas shielding or impurities.

- Lack of fusion: Incomplete melting of the base metal, resulting in weak joints.

- Undercut: Grooves melted into the base metal around the weld bead due to excessive welding heat.

- Cold lap: A joint where the weld metal fails to fuse properly, creating a weak area.

6. How do you prevent welding defects in MIG welding?

- Proper shielding gas selection and flow rate: Ensures adequate protection against weld pool contamination.

- Correct welding parameters: Optimizes heat input and penetration to minimize defects.

- Clean surfaces: Removes impurities that can cause porosity.

- Proper joint preparation: Ensures good fit-up and eliminates gaps that can lead to undercutting.

7. What are the safety precautions to consider when MIG welding?

- Wear appropriate protective gear: Welding helmet, gloves, and fire-resistant clothing.

- Ventilate the welding area: Remove welding fumes to prevent respiratory problems.

- Secure the workpiece: Prevent accidents and ensure weld quality.

- Handle welding equipment safely: Avoid electrical shocks and fires.

8. What are your experiences with different types of welding materials?

- Steels: Mild steel, stainless steel, alloy steel (e.g., 4130, 4140).

- Aluminum: Pure aluminum, aluminum alloys (e.g., 5052, 6061).

- Exotic materials: Titanium, nickel alloys (e.g., Inconel, Monel).

9. Describe your understanding of AWS D1.1 structural welding code.

- Specifies requirements for the design, fabrication, and inspection of welded structures: Ensures safety and reliability.

- Covers materials, joint preparation, welding procedures, and inspection methods: Provides a comprehensive framework for welding practices.

- Compliance ensures code-compliant welds: Meets industry standards and quality requirements.

10. How do you stay up-to-date with the latest welding technologies and techniques?

- Attend industry conferences and workshops: Learn about new developments and best practices.

- Read technical literature and research papers: Keep abreast of scientific advancements.

- Seek training and certification: Enhance skills and demonstrate proficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mig-Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mig-Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

MIG Welders are responsible for joining metal components using a metal inert gas (MIG) welding process. They play a crucial role in various industries, including manufacturing, construction, and automotive repair.

1. Welding Operations

MIG Welders are proficient in operating MIG welding equipment and using various welding techniques, such as gas metal arc welding (GMAW) and flux-cored arc welding (FCAW). They must be able to interpret welding blueprints and specifications to ensure accurate and high-quality welds.

- Setting up and operating MIG welding equipment, including selecting appropriate wire, gas, and welding parameters.

- Performing various welding techniques, such as butt welds, fillet welds, and edge welds, to join metal components.

- Inspecting and testing welds to ensure they meet specified quality standards.

2. Material Handling

As they work with heavy metal components, MIG Welders need to be able to handle and move materials safely and efficiently. This includes loading and unloading materials from workbenches or welding equipment, as well as using proper lifting techniques to prevent injuries.

- Loading and unloading metal components from workbenches or welding equipment using appropriate lifting techniques.

- Positioning and securing metal components for welding operations to ensure accuracy and safety.

3. Quality Control

Ensuring the quality of welds is a critical responsibility of MIG Welders. They must be able to identify and correct defects in welds, such as porosity, undercuts, and spatter, to maintain high standards of workmanship.

- Inspecting welds visually and using non-destructive testing methods to identify defects and ensure quality.

- Taking corrective actions to address defects, such as re-welding or grinding, to meet specified quality standards.

4. Safety and Maintenance

MIG Welders must adhere to safety regulations and maintain a clean and organized work area to prevent accidents and ensure the proper functioning of welding equipment.

- Following safety protocols, such as wearing appropriate protective gear and using proper ventilation techniques.

- Maintaining welding equipment, including cleaning and replacing consumables, to ensure optimal performance.

Interview Tips

Interview preparation is essential for any job seeker, and MIG Welders are no exception. Here are some tips to help candidates ace their interview:

1. Research the Company and Position

Before the interview, candidates should thoroughly research the company and the specific position they are applying for. This will enable them to demonstrate their knowledge of the company’s operations, values, and the requirements of the role.

- Visit the company’s website to learn about their history, products or services, and industry presence.

- Read online reviews and articles about the company to gain insights into its culture and work environment.

2. Practice Common Interview Questions

There are certain questions that are commonly asked in MIG Welder interviews. By practicing their responses beforehand, candidates can feel more confident and prepared during the actual interview.

- Can you describe your experience with different welding techniques, such as GMAW and FCAW?

- How do you ensure the quality of your welds and address any defects?

- Can you provide examples of projects where you successfully applied your MIG welding skills?

3. Showcase Skills and Experience

The interview is an opportunity for candidates to highlight their skills and experience that align with the job requirements. They should provide specific examples of their welding projects, emphasizing their proficiency in operating MIG welding equipment, their attention to detail, and their ability to meet quality standards.

- Use the STAR method (Situation, Task, Action, Result) to structure their answers and provide concrete examples of their work.

- Quantify their accomplishments whenever possible, using numbers and metrics to demonstrate their impact.

4. Prepare Technical Questions

In addition to general interview questions, candidates may also be asked technical questions to assess their knowledge and expertise in MIG welding. They should be prepared to discuss topics such as welding metallurgy, welding codes and standards, and troubleshooting welding equipment.

- Familiarize themselves with industry-specific terminology and best practices.

- Review welding safety regulations and standards.

5. Dress Professionally and Arrive Punctually

First impressions matter, so candidates should dress appropriately for the interview. Business casual attire is typically recommended, and they should ensure their clothes are clean and pressed. Additionally, arriving on time for the interview demonstrates respect and punctuality.

- Choose clothing that is comfortable and allows for movement, as they may be asked to demonstrate their welding skills.

- Be mindful of personal hygiene and arrive well-groomed.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mig-Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!