Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milk Drier position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

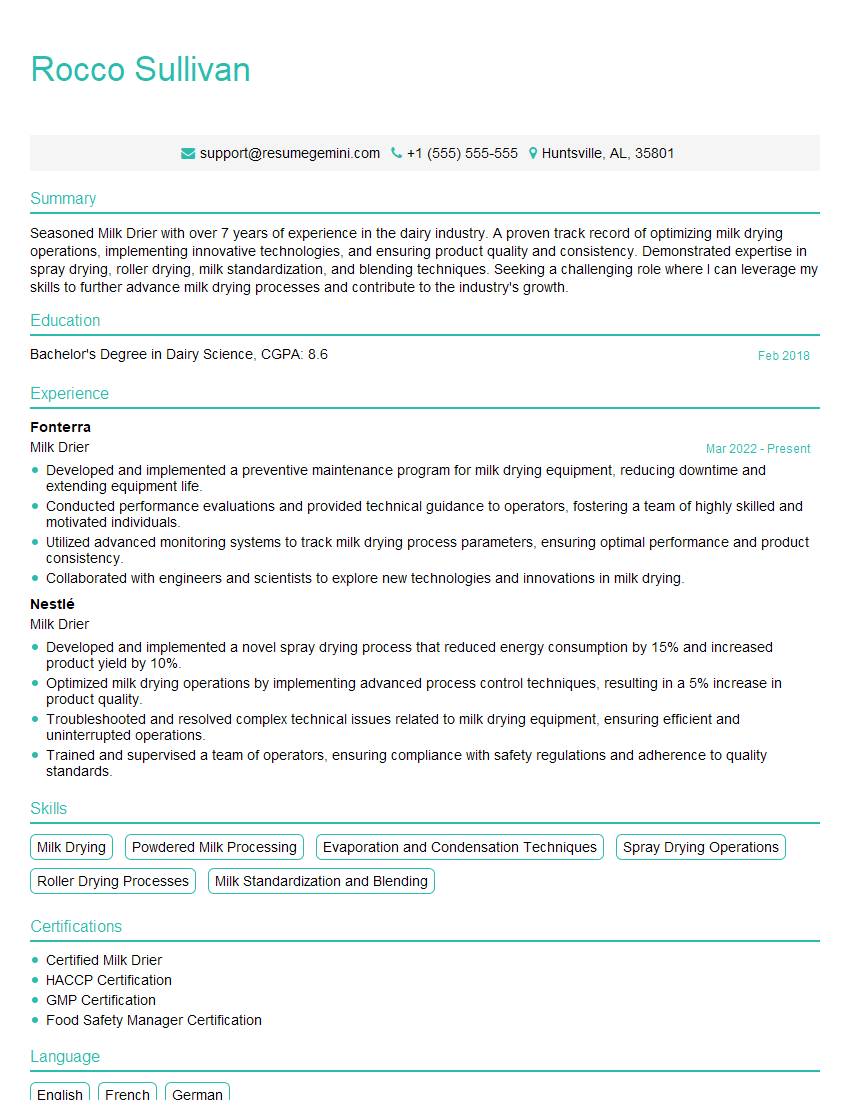

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milk Drier

1. How would you design a milk drying system for a dairy plant?

Sample Answer:

- Assess the requirements: Determine the desired capacity, moisture content, and quality of the dried milk.

- Select the drying technology: Evaluate spray drying, fluidized bed drying, or vacuum drying based on efficiency, cost, and product characteristics.

- Design the drying chamber: Optimize airflow, temperature, and residence time to achieve desired drying conditions.

- Incorporate moisture removal systems: Use cyclones, electrostatic precipitators, or scrubbers to collect and remove moisture from the exhaust air.

- Integrate powder handling systems: Design conveyors, storage silos, and packing equipment for efficient powder handling and storage.

2. What are the key factors to consider when selecting a milk drying system?

Sample Answer:

- Product quality: Moisture content, particle size, and functional properties of the dried milk.

- Drying capacity: Production output required to meet demand.

- Energy efficiency: Operating costs and environmental impact of the drying process.

- Maintenance and cleaning: Ease of maintenance and frequency of cleaning to ensure hygiene and product quality.

- Capital and operating costs: Investment and ongoing expenses associated with the system.

3. How do you optimize the energy efficiency of a milk drying system?

Sample Answer:

- Proper insulation: Minimize heat loss from the drying chamber.

- Heat recovery systems: Utilize waste heat from the exhaust air to preheat incoming milk or air.

- Variable speed drives: Adjust fan speeds to optimize airflow and reduce energy consumption.

- Efficient burner operation: Ensure proper combustion and optimize air-to-fuel ratios.

- Control and monitoring systems: Implement automated controls to monitor and adjust operating parameters for optimal efficiency.

4. What are the common troubleshooting steps for a milk drying system?

Sample Answer:

- Insufficient drying: Inspect feed rate, airflow, and temperature; check for blockages or leaks.

- High moisture content: Adjust drying temperature, residence time, or nozzle settings; clean moisture removal equipment.

- Powder caking: Optimize drying conditions, impeller speed, or powder handling equipment.

- Equipment malfunction: Check electrical connections, motors, and sensors; follow maintenance schedules.

- Product contamination: Inspect equipment for leaks, clean thoroughly, and monitor environmental conditions.

5. How do you ensure the safety and hygiene of a milk drying system?

Sample Answer:

- Regular cleaning and sanitation: Implement a robust cleaning and disinfection schedule to eliminate microorganisms and prevent contamination.

- Equipment maintenance: Regularly inspect and maintain all components to ensure proper operation and prevent breakdowns.

- Personnel training: Train operators on proper handling, cleaning, and safety protocols.

- HACCP plan: Implement a Hazard Analysis and Critical Control Points (HACCP) plan to identify and mitigate potential hazards.

- Environmental monitoring: Monitor temperature, humidity, and air quality to ensure proper drying conditions and prevent microbial growth.

6. What are the latest technologies and advancements in milk drying systems?

**Sample Answer:

- Membrane filtration: Pre-concentrate milk before drying to reduce energy consumption.

- Advanced spray drying techniques: Optimize particle size and distribution through controlled atomization and air flow.

- Intelligent control systems: Integrate sensors and data analytics to optimize drying parameters and reduce waste.

- Hybrid drying systems: Combine different drying technologies (e.g., spray and vacuum drying) to enhance efficiency and product quality.

- Sustainable drying methods: Utilize renewable energy sources, reduce waste, and minimize environmental impact.

7. How do you handle the challenges of drying milk with varying composition and properties?

Sample Answer:

- Product analysis: Conduct thorough analysis of milk composition to determine its characteristics.

- Optimization of drying parameters: Adjust temperature, feed rate, and nozzle settings to accommodate variations in milk properties.

- Blending and standardization: Mix milk from different sources or add additives to achieve consistent drying performance.

- Monitoring and adjustment: Continuously monitor drying conditions and make adjustments as needed to ensure desired product quality.

8. What are the key factors to consider when designing a milk drying plant layout?

Sample Answer:

- Process flow: Optimize the flow of materials and equipment to ensure efficient production.

- Equipment placement: Position equipment strategically to minimize maintenance, downtime, and cross-contamination.

- Material handling: Design efficient systems for transporting milk, powder, and other materials throughout the plant.

- Safety and ergonomics: Ensure a safe and comfortable working environment for operators.

- Maintenance access: Provide adequate access to equipment for maintenance and repairs.

9. How do you manage the quality and consistency of the dried milk product?

**Sample Answer:

- Raw milk inspection: Establish strict standards for incoming milk to ensure its quality.

- Process control: Implement robust controls to monitor and maintain critical drying parameters.

- Product testing: Conduct regular laboratory testing to verify product specifications.

- Statistical analysis: Analyze data to identify process variations and implement corrective actions.

- Customer feedback: Monitor customer feedback and make adjustments as needed to meet their quality expectations.

10. What are the challenges and opportunities in the milk drying industry?

**Sample Answer:

Challenges:

- Fluctuating raw milk supply and prices.

- Increasing demand for high-quality milk powders.

- Regulatory compliance and environmental sustainability.

Opportunities:

- Growing global demand for milk powder.

- Advancements in drying technologies and efficiency.

- Development of value-added milk powder products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milk Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milk Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate and Monitor Milk Drying Equipment

Operate and monitor milk drying equipment, ensuring that it functions efficiently and safely.

- Oversee the drying process, regulating temperature, humidity, and other parameters to produce high-quality milk powder.

- Monitor equipment sensors and gauges to identify potential problems and take corrective action.

2. Maintain and Clean Equipment

Perform regular maintenance and cleaning of milk drying equipment to ensure optimal performance and prevent contamination.

- Clean and sanitize equipment surfaces using appropriate chemicals and methods.

- Inspect and maintain equipment components, such as filters, belts, and nozzles.

- Troubleshoot and repair minor equipment malfunctions.

3. Monitor Production Quality

Monitor production quality by conducting regular inspections and tests on milk powder samples.

- Conduct organoleptic evaluations (e.g., appearance, texture, taste) of milk powder.

- Perform laboratory tests to assess milk powder composition, moisture content, and other quality parameters.

- Identify and resolve any quality issues that may arise during the drying process.

4. Ensure Compliance with Safety Regulations

Ensure compliance with established safety regulations and protocols in the milk drying facility.

- Follow good manufacturing practices (GMPs) and adhere to food safety standards.

- Wear appropriate personal protective equipment (PPE) and maintain a clean and sanitary work environment.

- Report any potential safety hazards or incidents to supervisors.

5. Maintain Inventory and Prepare Reports

Maintain inventory of raw materials and finished products, ensuring adequate supply.

- Order raw materials and schedule deliveries as needed.

- Prepare production reports and other documentation related to the milk drying process.

- Collaborate with other departments, such as quality control and production planning, to ensure smooth operations.

Interview Tips

Preparing for an interview for a Milk Drier position requires a combination of technical knowledge and a clear understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, research the company you are applying to and the dairy industry as a whole. Demonstrate your knowledge of the milk drying process, industry trends, and the company’s specific operations.

- Visit the company’s website and social media pages to gather information about their products, services, and culture.

- Read industry publications and news articles to stay updated on current developments in milk drying technology and regulations.

2. Highlight Your Technical Skills

Emphasize your technical skills and experience in milk drying equipment operation, maintenance, and quality control. Quantify your accomplishments whenever possible.

- Describe your experience in operating and maintaining different types of milk drying equipment.

- Provide examples of how you have improved production efficiency or resolved quality issues by implementing specific techniques.

- Highlight your knowledge of milk powder composition, quality standards, and testing procedures.

3. Demonstrate Your Safety and Compliance Awareness

Stress your understanding of and commitment to safety and compliance in the milk drying industry. Explain how you have ensured compliance with GMPs and food safety regulations in previous roles.

- Describe your experience in maintaining a clean and sanitary work environment.

- Highlight your knowledge of emergency procedures and safety protocols.

- Explain how you would contribute to the company’s safety and compliance initiatives.

4. Prepare for Behavioral Questions

Be prepared to answer behavioral interview questions that assess your problem-solving skills, teamwork abilities, and work ethic. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Describe a situation where you had to troubleshoot a complex problem in a milk drying facility.

- Explain how you collaborated with colleagues to improve production efficiency or reduce downtime.

- Provide an example of how you handled a stressful or challenging situation in a professional manner.

5. Ask Insightful Questions

Towards the end of the interview, ask insightful questions to show your interest in the position and the company. This is an opportunity to clarify any doubts and demonstrate your knowledge of the industry.

- Inquire about the company’s future plans for milk drying technology and process optimization.

- Ask about opportunities for professional development and training.

- Show enthusiasm for the role and express how your skills and experience align with the company’s goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Milk Drier interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!