Are you gearing up for a career in Milk Drying Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Milk Drying Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

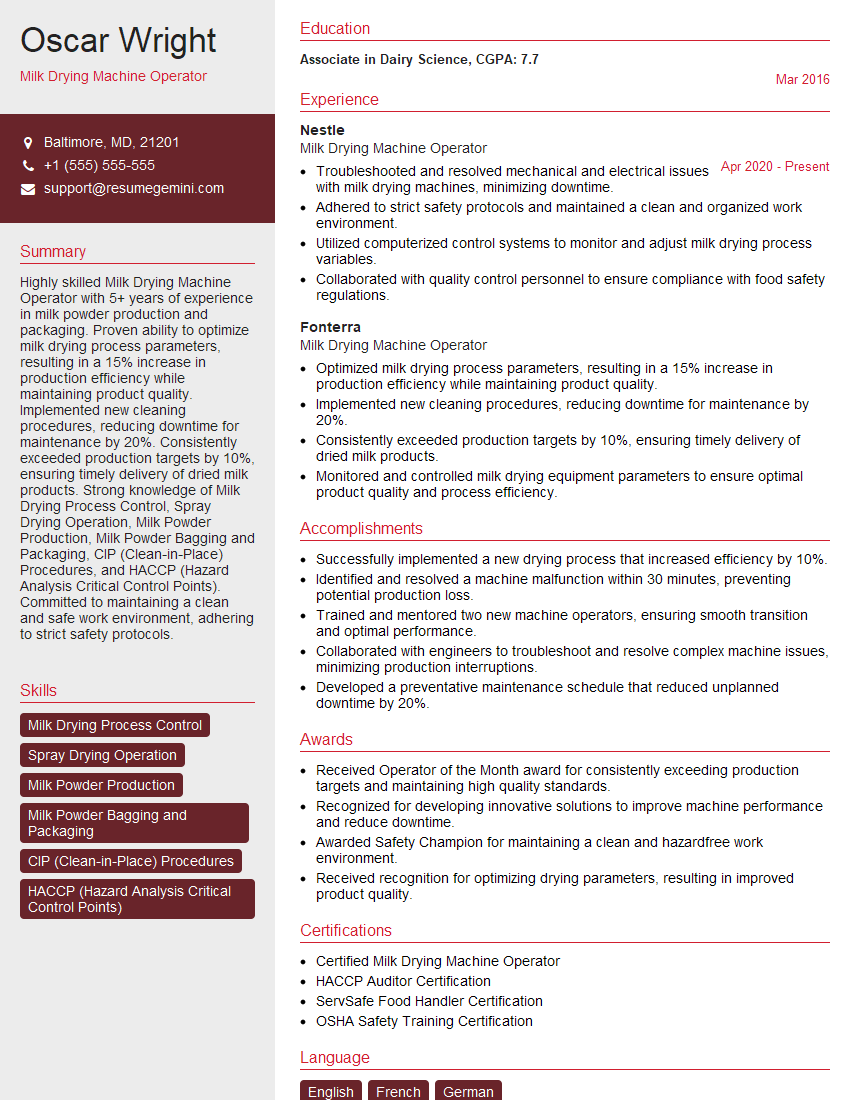

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milk Drying Machine Operator

1. How do you ensure the milk powder meets the desired moisture and fat content specifications?

To ensure the milk powder meets the desired moisture and fat content specifications, I follow these key steps:

- Control feed rate: I monitor and adjust the feed rate of milk into the dryer to maintain a consistent flow and prevent over or under-drying.

- Control atomization: I optimize the atomization process by adjusting the pressure and nozzle size to ensure proper dispersion of milk droplets, which influences moisture removal and powder quality.

- Monitor drying temperature: I closely monitor the drying temperature and adjust it as needed to effectively remove moisture without compromising the powder’s properties.

- Conduct regular moisture and fat analysis: I perform regular moisture and fat analysis on the milk powder using established methods to ensure compliance with specifications.

2. Describe the maintenance procedures you perform on the milk drying machine.

Daily Maintenance:

- Check and clean nozzles for blockages.

- Inspect and clean feed pumps.

- Monitor and adjust belt tension.

Weekly Maintenance:

- Lubricate bearings and moving parts.

- Inspect and clean cyclone for powder buildup.

- Calibrate moisture and fat sensors.

Monthly Maintenance:

- Thorough cleaning of the entire system, including atomizer, dryer chamber, and cyclone.

- Inspect and replace worn or damaged components.

- Perform vibration analysis to identify potential issues.

3. How do you troubleshoot common problems that occur with milk drying machines?

- Clogged nozzles: I inspect and clear the nozzles to restore proper atomization.

- Insufficient drying: I check the feed rate, atomization settings, and drying temperature to identify and adjust the root cause.

- Excess moisture: I adjust the drying parameters, check the cyclone efficiency, and inspect for any leaks in the system.

- Powder contamination: I conduct a thorough inspection of the equipment, piping, and environment to identify the source of contamination and implement corrective measures.

- Mechanical issues: I check the belts, bearings, and other mechanical components for wear or damage, and promptly address any issues to prevent breakdowns.

4. What safety precautions do you take when operating the milk drying machine?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a lab coat.

- Ensure the machine is properly grounded and electrically safe.

- Follow established operating procedures and avoid making unauthorized modifications.

- Be aware of potential hazards, such as hot surfaces, moving machinery, and dust, and take appropriate precautions.

- Report any safety concerns or incidents promptly to the supervisor.

5. How do you optimize the efficiency of the milk drying process?

Optimizing the efficiency of the milk drying process involves the following strategies:

- Optimizing feed concentration: Adjusting the solids content of the milk feed to the optimal level for efficient drying.

- Fine-tuning drying conditions: Setting the drying temperature, air flow rate, and residence time to maximize moisture removal while preserving powder quality.

- Regular maintenance: Following preventive maintenance schedules to minimize downtime and ensure optimal performance.

- Monitoring and control: Using sensors and control systems to monitor key parameters and make real-time adjustments to maintain efficiency.

- Operator training: Ensuring operators are well-trained and have a thorough understanding of the process to make informed decisions.

6. What are the different types of milk drying systems available?

- Spray drying: This method involves atomizing milk into a hot air stream, resulting in the rapid evaporation of moisture and the formation of powder.

- Freeze drying: In this process, milk is first frozen and then subjected to a vacuum, causing the water to sublime directly from the solid phase to vapor.

- Roller drying: This method involves spreading milk onto heated rollers, where the moisture evaporates, leaving behind a dried sheet that is then broken into powder.

7. How do you handle emergencies related to the milk drying machine?

- Equipment failure: I immediately shut down the machine, isolate the problem, and contact maintenance personnel.

- Fire: I activate the nearest fire alarm, evacuate the area, and follow established fire safety procedures.

- Spills: I contain the spill using absorbent materials, clean the area thoroughly, and report the incident.

- Product contamination: I quarantine the affected product, investigate the cause, and implement corrective actions to prevent recurrence.

- Injuries: I provide first aid if necessary, call for medical assistance, and report the incident to the supervisor.

8. What are the key performance indicators (KPIs) used to measure the effectiveness of the milk drying operation?

- Powder yield: The ratio of milk powder produced to the amount of milk solids fed into the dryer.

- Moisture content: The amount of moisture remaining in the milk powder, which affects its stability and quality.

- Fat content: The amount of fat in the milk powder, which influences its nutritional value and flavor.

- Production capacity: The amount of milk powder produced per unit of time.

- Energy efficiency: The amount of energy required to produce a given amount of milk powder.

9. How do you stay updated on the latest technologies and best practices in milk drying?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Network with other professionals in the field.

- Seek out training opportunities provided by equipment manufacturers and industry organizations.

10. Are you familiar with the HACCP (Hazard Analysis and Critical Control Points) system?

- Yes, I am familiar with the HACCP system. It is a systematic approach to identifying, assessing, and controlling food safety hazards.

- In the context of milk drying, HACCP involves identifying potential hazards, such as microbial contamination, chemical contamination, and physical hazards.

- Critical control points (CCPs) are identified where hazards can be controlled or eliminated, and monitoring and corrective action procedures are established.

- By following HACCP principles, we can ensure the production of safe and high-quality milk powder.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milk Drying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milk Drying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Milk Drying Machine Operator is responsible for managing and monitoring the operation of milk drying machines. The primary objective is to ensure the production of high-quality milk powder while adhering to safety and hygiene standards.

1. Machine Operation and Monitoring

intro paragraph

- Operate different types of milk drying machines, including spray dryers and fluidized bed dryers

- Monitor machine settings and parameters to maintain optimal drying conditions

2. Production Management

intro paragraph

- Manage the production process to ensure the required quantity and quality of milk powder

- Control the flow of raw materials (milk) into the drying machines

3. Quality Control

intro paragraph

- Take samples of milk powder for quality testing and ensure the product meets specifications

- Monitor and control process parameters to prevent contamination and defects

4. Equipment Maintenance

intro paragraph

- Perform routine maintenance on milk drying machines to ensure smooth operation

- Troubleshoot and resolve equipment issues promptly

Interview Tips

Preparing adequately for an interview can significantly improve your chances of success. Here are some tips to help candidates ace an interview for a Milk Drying Machine Operator position:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the Milk Drying Machine Operator role. This will enable you to tailor your answers to the interviewer’s questions and demonstrate your understanding of the industry.

- Visit the company’s website to learn about their products, services, and culture.

- Read job descriptions carefully to identify the key responsibilities and qualifications required.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experiences.

- Examples of common interview questions include: “Tell me about your experience operating milk drying machines?” or “How do you ensure the quality of milk powder produced?”

- Use the STAR method to highlight your accomplishments and demonstrate how you have applied your skills in previous roles.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as proficiency in operating milk drying machines, understanding of drying processes, and knowledge of quality control procedures. Additionally, share examples of your problem-solving abilities, attention to detail, and ability to work effectively in a production environment.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Provide specific examples of how you have overcome challenges or implemented improvements in your previous roles.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your curiosity about the company, the position, and the industry. This also gives you an opportunity to clarify any information or address any concerns.

- Examples of questions you could ask include: “What are the company’s growth plans for the future?” or “What professional development opportunities are available for employees?”

- Avoid asking questions that are easily answered by researching the company online.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Milk Drying Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!