Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mill Attendant position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

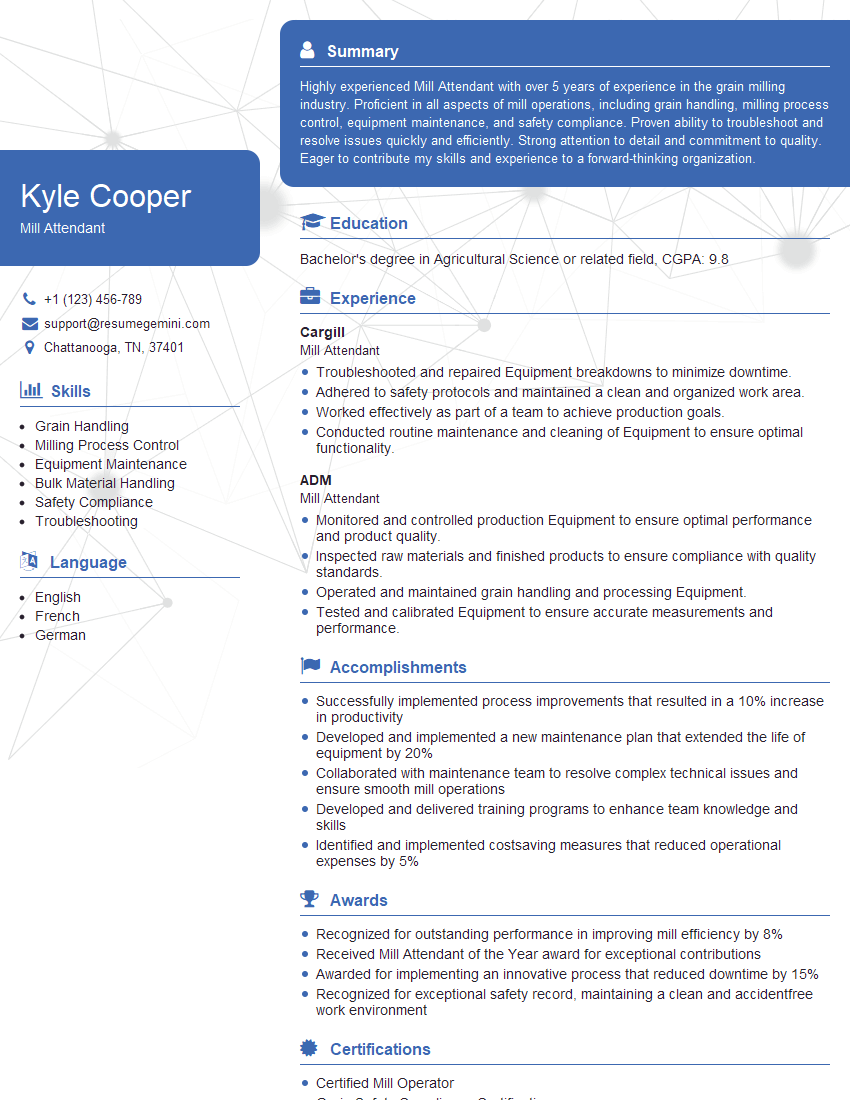

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Attendant

1. Describe the key responsibilities of a Mill Attendant?

As a Mill Attendant, I would be responsible for:

- Monitoring and controlling the operation of milling machines

- Maintaining and repairing milling equipment

- Ensuring that the milling process meets quality standards

- Maintaining a clean and safe work environment

- Working as part of a team to achieve production goals

2. What are the different types of milling machines and what are their functions?

Horizontal Milling Machine

- Used for machining flat surfaces, slots, and other features on workpieces

- The table moves in the X and Y axes, while the spindle moves in the Z axis

Vertical Milling Machine

- Used for machining vertical surfaces, pockets, and other features on workpieces

- The table moves in the X and Y axes, while the spindle moves in the Z axis

Universal Milling Machine

- Used for machining a variety of features on workpieces, including flat surfaces, slots, pockets, and angles

- The table can be tilted and rotated, allowing for complex machining operations

CNC Milling Machine

- Used for machining complex parts with high precision and repeatability

- The machine is controlled by a computer program that guides the movement of the cutting tool

3. What are the different types of milling cutters and when are they used?

The type of milling cutter used depends on the material being milled and the desired finish.

- End mills are used for machining flat surfaces, slots, and pockets

- Face mills are used for machining large flat surfaces

- Shell mills are used for machining curved surfaces

- Ball mills are used for machining complex shapes

4. What are the safety precautions that must be taken when operating a milling machine?

When operating a milling machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, ear protection, and gloves

- Keep the work area clean and free of debris

- Secure the workpiece properly before starting the machine

- Use sharp cutting tools and keep them properly maintained

- Never reach into the cutting area while the machine is running

- Follow all manufacturer’s instructions for safe operation

5. How do you troubleshoot common problems that can occur when operating a milling machine?

Some common problems that can occur when operating a milling machine include:

- Chattering, which can be caused by worn cutting tools, improper workpiece setup, or excessive vibration

- Burrs, which can be caused by dull cutting tools or improper feed rates

- Overheating, which can be caused by excessive cutting speeds or feed rates

- Breakage, which can be caused by using worn cutting tools or applying too much force

6. What are the different types of materials that can be milled?

The type of material that can be milled depends on the cutting tool being used and the desired finish.

- Metals, such as steel, aluminum, and brass

- Plastics, such as acrylic, polycarbonate, and polyethylene

- Wood

- Composite materials, such as fiberglass and carbon fiber

7. What are the different types of finishes that can be achieved when milling?

The type of finish that can be achieved when milling depends on the cutting tool being used, the feed rate, and the workpiece material.

- Roughing, which is used to remove large amounts of material quickly

- Finishing, which is used to create a smooth, precise finish

- Polishing, which is used to create a mirror-like finish

8. What are the different types of fluids that can be used when milling?

The type of fluid that is used when milling depends on the material being milled and the desired finish.

- Cutting oil, which is used to lubricate the cutting tool and workpiece

- Coolant, which is used to cool the cutting tool and workpiece

- Air, which is used to blow away chips and debris

9. What are the different types of measurement tools that are used when milling?

The type of measurement tool that is used when milling depends on the accuracy required.

- Calipers, which are used to measure the outside and inside dimensions of workpieces

- Micrometers, which are used to measure the thickness of workpieces

- Dial indicators, which are used to measure the runout of workpieces

- Optical comparators, which are used to compare the shape of workpieces to a known standard

10. How do you maintain a milling machine?

To maintain a milling machine, it is important to:

- Clean the machine regularly to remove chips and debris

- Lubricate the machine regularly to prevent wear and tear

- Inspect the machine regularly for any signs of damage or wear

- Calibrate the machine regularly to ensure accuracy

- Follow all manufacturer’s instructions for maintenance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Attendant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Attendant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Attendants play a crucial role in the smooth operation of mills, ensuring the efficient production of raw materials. Their responsibilities encompass a wide range of tasks, including monitoring equipment, performing routine maintenance, and adhering to safety protocols.

1. Equipment Monitoring

Constant vigilance is required to ensure that all equipment is functioning optimally. Mill Attendants are responsible for monitoring gauges, meters, and other indicators to detect any abnormalities. Promptly identifying and reporting any deviations from normal operating parameters is essential to prevent equipment failures and maintain production efficiency.

- Monitoring gauges, meters, and other indicators

- Identifying and reporting equipment abnormalities

2. Routine Maintenance

Regular maintenance is crucial to prevent equipment breakdowns and extend the lifespan of machinery. Mill Attendants perform routine maintenance tasks such as lubrication, cleaning, and minor repairs. By proactively addressing potential issues, they help ensure uninterrupted production and minimize downtime.

- Lubrication and cleaning of equipment

- Performing minor repairs

3. Safety Compliance

Mills can be hazardous environments, and adhering to safety protocols is paramount. Mill Attendants must be familiar with all safety regulations and procedures. They are responsible for wearing appropriate protective gear, following lockout/tagout procedures, and reporting any unsafe conditions. By prioritizing safety, they help create a safe working environment for themselves and their colleagues.

- Wearing appropriate protective gear

- Following lockout/tagout procedures

- Reporting unsafe conditions

4. Production Support

Mill Attendants provide support to other departments to ensure smooth production flow. They assist in loading and unloading raw materials, monitor production rates, and help with troubleshooting. By working closely with other team members, they contribute to the overall efficiency and productivity of the mill.

- Assisting in loading and unloading raw materials

- Monitoring production rates

- Troubleshooting production issues

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Mill Attendant position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Familiarize yourself with the company’s mission, values, and industry standing. Understanding the role’s responsibilities and requirements will enable you to tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Prepare questions to ask the interviewer about the company and position

2. Highlight Relevant Skills and Experience

Review the job description carefully and identify the skills and experience that are most relevant to the position. Emphasize these in your resume and during the interview. Provide specific examples of your accomplishments and how they demonstrate your ability to perform the job effectively.

- Quantify your accomplishments using specific metrics

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences

- Tailor your answers to the specific requirements of the position

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. Anticipate questions about your experience, skills, and why you are interested in the position. rehearsing your answers will help you feel confident and articulate during the interview.

- Prepare answers to questions about your strengths and weaknesses

- Practice describing your experience and skills using the STAR method

- Research common interview questions and prepare your answers

4. Dress Professionally and Be On Time

First impressions matter, so it is important to dress professionally for your interview. Arrive on time to demonstrate your respect for the interviewer’s time. Being punctual and well-dressed will convey a positive and professional image.

- Wear business attire that is clean and pressed

- Arrive for your interview on time

- Be polite and respectful to the interviewer

5. Be Enthusiastic and Ask Questions

Show your enthusiasm for the position and the company during the interview. Ask thoughtful questions to demonstrate your interest and engagement. Inquiring about the company’s culture, growth opportunities, and commitment to safety will show that you are genuinely interested in the role and the organization.

- Express your enthusiasm for the position and the company

- Ask thoughtful questions about the company and the position

- Thank the interviewer for their time

Next Step:

Now that you’re armed with the knowledge of Mill Attendant interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mill Attendant positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini