Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mill Hand interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mill Hand so you can tailor your answers to impress potential employers.

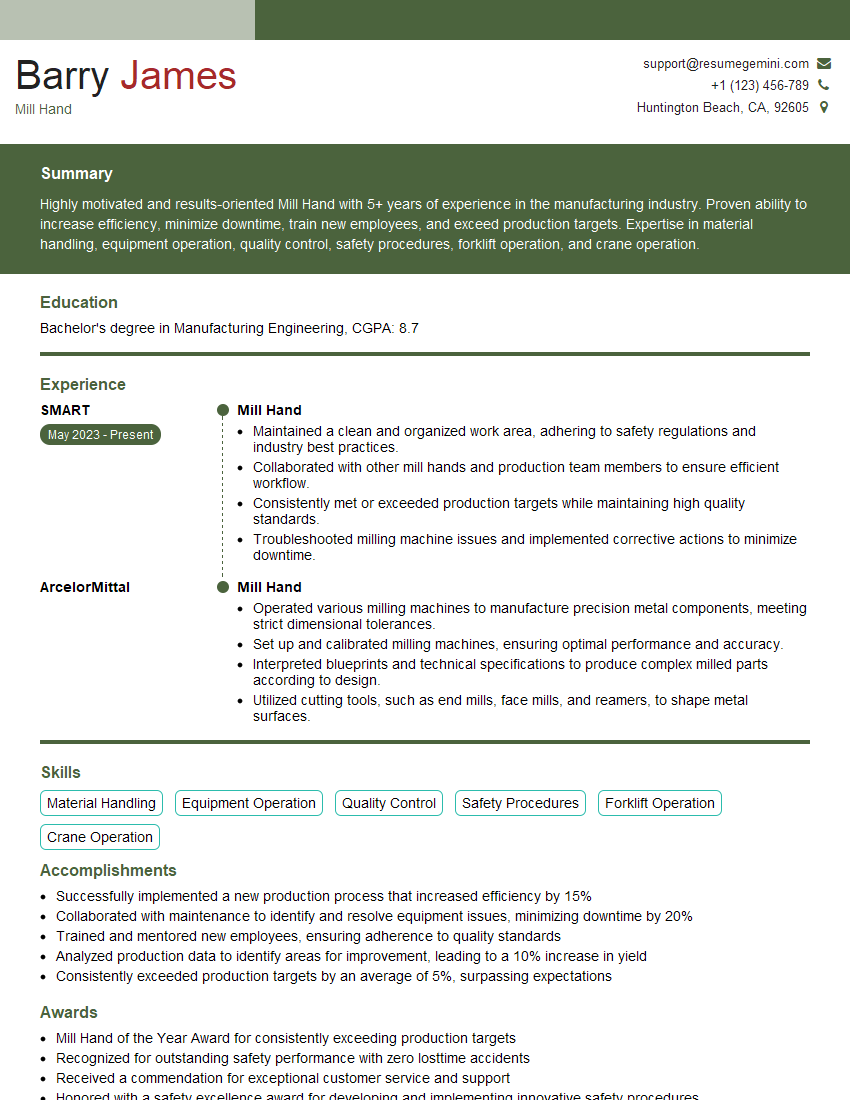

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Hand

1. What types of materials can be processed in a mill and what are the different types of mills used for each material?

Mills can process a wide variety of materials, including grains, minerals, and chemicals. The type of mill used will depend on the material being processed and the desired end product.

- Hammer mills are used to grind brittle materials, such as grains and spices.

- Ball mills are used to grind hard materials, such as minerals and ores.

- Rod mills are used to grind materials that are too large for ball mills, such as rocks and boulders.

- Attritor mills are used to grind materials that are very fine, such as pigments and pharmaceuticals.

2. What are the different types of milling processes and what are the advantages and disadvantages of each?

Batch milling

- Advantages: Batch milling is more flexible than continuous milling, as it allows for the processing of smaller batches of material.

- Disadvantages: Batch milling is less efficient than continuous milling, as it requires more time to set up and clean the mill.

Continuous milling

- Advantages: Continuous milling is more efficient than batch milling, as it allows for the processing of larger batches of material.

- Disadvantages: Continuous milling is less flexible than batch milling, as it can be difficult to change the milling process once it has started.

3. What are the different factors that affect the milling process and how can they be controlled?

- The speed of the mill

- The temperature of the mill

- The size of the grinding media

- The ratio of material to grinding media

- The moisture content of the material

4. What are the different types of mill liners and what are the advantages and disadvantages of each?

- Rubber liners are the most common type of mill liner. They are durable and have a long lifespan.

- Ceramic liners are more expensive than rubber liners, but they are harder and more resistant to wear.

- Metal liners are the most expensive type of mill liner. They are very hard and resistant to wear, but they can be noisy and can contaminate the material being processed.

5. What are the different types of mill feeders and what are the advantages and disadvantages of each?

- Vibratory feeders are the most common type of mill feeder. They are simple to operate and maintain.

- Screw feeders are more expensive than vibratory feeders, but they are more accurate and can feed material at a higher rate.

- Belt feeders are the most expensive type of mill feeder. They are very accurate and can feed material at a very high rate, but they can be difficult to operate and maintain.

6. What are the different types of mill discharges and what are the advantages and disadvantages of each?

- Gravity discharges are the most common type of mill discharge. They are simple to operate and maintain.

- Pneumatic discharges are more expensive than gravity discharges, but they are more efficient and can discharge material at a higher rate.

- Hydraulic discharges are the most expensive type of mill discharge. They are very efficient and can discharge material at a very high rate, but they can be difficult to operate and maintain.

7. What are the different types of mill safety devices and what are the advantages and disadvantages of each?

- Mechanical safety devices are the most common type of mill safety device. They are simple to operate and maintain.

- Electrical safety devices are more expensive than mechanical safety devices, but they are more reliable and can protect against a wider range of hazards.

- Hydraulic safety devices are the most expensive type of mill safety device. They are very reliable and can protect against a very wide range of hazards, but they can be difficult to operate and maintain.

8. What are the different types of mill maintenance tasks and how often should they be performed?

- Daily maintenance tasks include checking the mill for leaks, vibration, and noise.

- Weekly maintenance tasks include cleaning the mill, lubricating the bearings, and inspecting the mill liners.

- Monthly maintenance tasks include changing the mill oil, inspecting the mill gears, and calibrating the mill sensors.

- Annual maintenance tasks include overhauling the mill and replacing the mill liners.

9. What are the different types of mill troubleshooting problems and how can they be solved?

- If the mill is not grinding properly, the grinding media may need to be replaced.

- If the mill is vibrating excessively, the mill liners may need to be replaced.

- If the mill is making a lot of noise, the mill bearings may need to be lubricated.

- If the mill is leaking, the mill seals may need to be replaced.

10. What are the different types of mill certifications and what do they mean?

- The ISO 9001 certification is a quality management system certification that ensures that the mill meets certain quality standards.

- The ISO 14001 certification is an environmental management system certification that ensures that the mill meets certain environmental standards.

- The OHSAS 18001 certification is an occupational health and safety management system certification that ensures that the mill meets certain health and safety standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Hands are responsible for the operation and maintenance of milling equipment in a variety of manufacturing settings. They may work in a variety of industries, including food processing, paper production, and metalworking.Their key job responsibilities include:

1. Operating milling equipment

Mill Hands are responsible for operating a variety of milling equipment, including grinders, crushers, and mixers.

- They must be able to operate this equipment safely and efficiently.

- They must also be able to troubleshoot and repair minor problems with the equipment.

2. Monitoring production

Mill Hands are responsible for monitoring the production process to ensure that the equipment is running properly and that the product is meeting specifications.

- They must be able to identify and correct any problems that arise during production.

- They must also be able to keep accurate records of production data.

3. Maintaining equipment

Mill Hands are responsible for maintaining the milling equipment to ensure that it is in good working order.

- This includes cleaning, lubricating, and adjusting the equipment.

- Mill Hands must also be able to identify and repair minor problems with the equipment.

4. Working with other team members

Mill Hands often work with other team members, including operators, supervisors, and engineers.

- They must be able to communicate effectively with others and work as part of a team.

- They must also be able to follow instructions and work independently.

Interview Tips

Preparing for a Mill Hand interview can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for.

- This will help you understand the company’s culture and values, and it will also give you a better idea of what the job entails.

- You should also be prepared to talk about your own skills and experience, and how they match the requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”.

- It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- You should also be prepared to answer questions about your experience and skills, and how they relate to the position you are applying for.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview.

- This means wearing clean, pressed clothes that are appropriate for the office environment.

- You should also avoid wearing excessive jewelry or perfume.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time.

- If you are running late, be sure to call or email the interviewer to let them know.

- It is also important to be prepared to wait a few minutes before your interview starts.

Next Step:

Now that you’re armed with the knowledge of Mill Hand interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mill Hand positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini