Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mill Oiler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

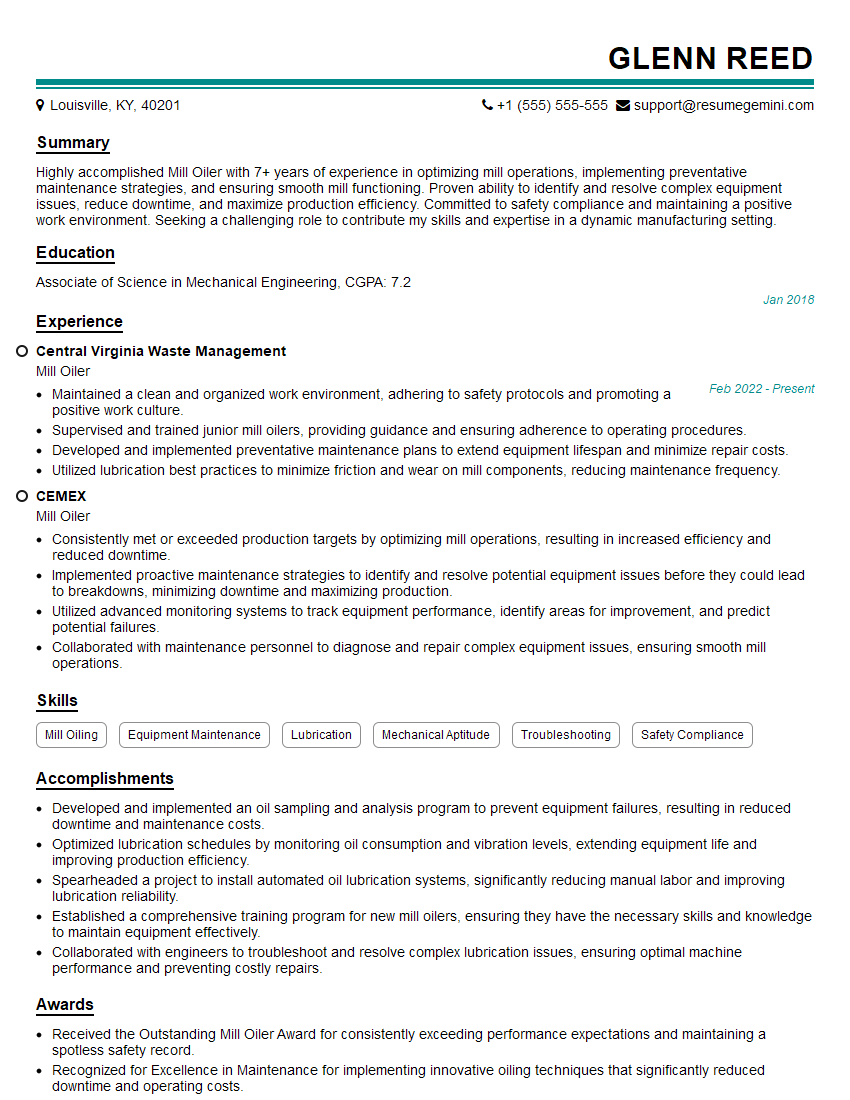

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Oiler

1. What are the primary responsibilities of a Mill Oiler?

- Lubricate machinery and equipment to prevent wear and ensure smooth operation.

- Monitor oil levels and add oil as needed.

- Inspect and clean oil reservoirs, filters, and other components.

- Troubleshoot lubrication problems and make repairs as necessary.

2. What are the different types of lubricants used in a mill?

- Oils: Mineral oils, synthetic oils, and vegetable oils.

- Greases: Calcium greases, lithium greases, and synthetic greases.

- Solid lubricants: Graphite, molybdenum disulfide, and boron nitride.

3. What are the factors to consider when selecting a lubricant?

- Type of equipment

- Operating conditions

- Environmental factors

- Cost

4. What are the different methods of lubrication?

- Manual lubrication

- Automatic lubrication

- Semi-automatic lubrication

5. What are the safety precautions that must be taken when working with lubricants?

- Wear protective clothing, including gloves and eye protection.

- Avoid skin contact with lubricants.

- Do not inhale lubricant vapors.

- Store lubricants in a safe and well-ventilated area.

6. What are the common problems that can occur with lubrication systems?

- Oil leaks

- Clogged filters

- Contaminated oil

- Improper lubrication

7. How do you troubleshoot and repair lubrication problems?

answer the question here in detail

The specific steps involved in troubleshooting and repairing lubrication problems will vary depending on the nature of the problem. However, some general steps that can be followed include:

- Identify the symptoms of the problem.

- Inspect the lubrication system for any obvious signs of damage or wear.

- Check the oil level and condition.

- Clean or replace any clogged filters.

- Flush the lubrication system with clean oil.

- Make any necessary repairs to the lubrication system.

8. What are the preventive maintenance tasks that can be performed to avoid lubrication problems?

- Regularly inspect the lubrication system for any signs of damage or wear.

- Check the oil level and condition.

- Change the oil and filters according to the manufacturer’s recommendations.

- Clean the lubrication system.

- Lubricate all moving parts.

9. What are the advantages of using a computerized lubrication system?

- Improved lubrication

- Reduced maintenance costs

- Increased uptime

- Improved safety

10. What is your experience with working on computerized lubrication systems?

answer the question here in detail

I have experience working on computerized lubrication systems for the past 5 years. I am familiar with the different types of computerized lubrication systems and their components. I have also experience in troubleshooting and repairing computerized lubrication systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Oilers are responsible for maintaining the smooth operation of machinery in industrial settings, ensuring that proper lubrication is applied to machinery parts.

1. Lubrication Duties

Oilers carry out lubrication tasks according to established schedules and procedures.

- Apply lubricants to various machine components like bearings, gears, and chains

- Monitor and refill oil and grease levels

2. Equipment Maintenance

Mill Oilers perform basic maintenance tasks to keep equipment operating efficiently.

- Inspect equipment for leaks, vibrations, and wear and tear

- Clean and adjust equipment as required

- Report any issues or malfunctions to supervisors

3. Safety and Compliance

Oilers prioritize safety and adhere to established protocols.

- Follow safety regulations and wear appropriate protective gear

- Maintain a clean and organized work area

- Dispose of hazardous materials according to regulations

4. Communication and Collaboration

Mill Oilers effectively communicate with team members.

- Collaborate with other maintenance technicians and operators

- Communicate any problems or suggestions to supervisors

Interview Tips

Preparing thoroughly for a Mill Oiler interview will increase your chances of success. Here are some helpful tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture.

- Visit the company’s website and social media pages

- Read industry news and articles about the company

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses.

- Introduce yourself and highlight your relevant skills

- Describe your experience in lubrication and equipment maintenance

- Explain your understanding of safety regulations

3. Emphasize Your Physical Aptitude

Mill Oilers perform physically demanding tasks. Emphasize your physical fitness.

- Highlight your ability to stand for long periods and lift heavy objects

- Mention any relevant physical activities or hobbies

4. Showcase Your Teamwork Skills

Mill Oilers often work as part of a team. Show that you are a collaborative worker.

- Give examples of working effectively in a team environment

- Explain how you communicate with different types of people

5. Ask Thoughtful Questions

Asking thoughtful questions shows that you are engaged and interested in the position.

- Inquire about the company’s training programs for Mill Oilers

- Ask about the company’s safety record and accident prevention measures

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mill Oiler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.