Are you gearing up for an interview for a Mill Roll Rewinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mill Roll Rewinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

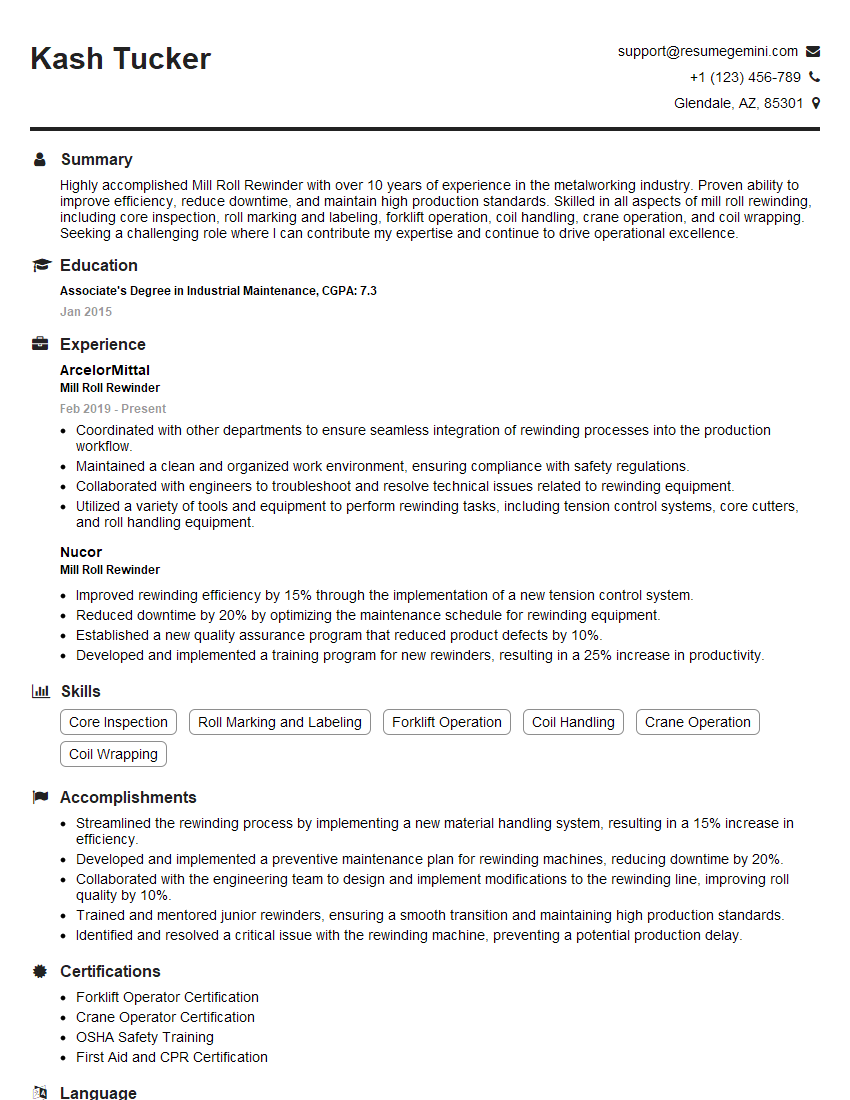

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Roll Rewinder

1. Explain the process of loading a mill roll onto the rewinder?

- Use a forklift to carefully lift the mill roll onto the loading platform.

- Align the mill roll with the rewinder’s axis and gently push it into place.

- Use the machine’s controls to secure the mill roll and begin the winding process.

2. How do you determine the optimal winding tension for different types of materials?

- Consider the material’s thickness, strength, and surface finish.

- Start with a low tension and gradually increase it until the material is secure without causing damage.

3. Describe the different types of splicing methods used in mill roll rewinding and their applications?

– Butt Splice: Overlapping the two ends of the material and adhering them together. – Lap Splice: Overlapping the two ends of the material and folding them over a third end. – Hot Melt Splice: Using a hot melt adhesive to bond the two ends of the material together. – Ultrasonic Splice: Using high-frequency sound waves to create a strong bond between the two ends of the material.

4. What are the common causes of web breaks during rewinding and how can they be prevented?

- Incorrect tension settings.

- Poorly spliced material.

- Improperly aligned rolls.

- Defective machine components.

5. How do you troubleshoot a mill roll rewinder that is not winding evenly?

- Check the tension settings.

- Inspect the material for any defects or irregularities.

- Examine the rollers for any buildup or damage.

- Check the machine’s alignment and make any necessary adjustments.

6. What are the safety precautions that must be followed when operating a mill roll rewinder?

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Keep hands and feet away from moving parts.

- Ensure the machine is properly grounded and maintained.

- Never attempt to clear a jam or make adjustments while the machine is running.

7. How do you maintain and calibrate a mill roll rewinder to ensure optimal performance?

– Regularly clean and inspect the machine’s components. – Calibrate the tension settings, web tension sensors, and speed controls. – Monitor the machine’s performance and make adjustments as needed.

8. What are the different types of defects that can occur during mill roll rewinding and how can they be identified and corrected?

– Wrinkles: Adjust the tension settings or replace defective material. – Edge breaks: Ensure proper alignment of the rolls and check the material for damage.

9. How do you optimize the speed and efficiency of a mill roll rewinder?

- Use a tension control system to maintain consistent winding tension.

- Choose the appropriate core size and roll diameter.

- Regularly maintain and calibrate the machine.

10. Describe the different types of mill roll rewinder systems and their advantages and disadvantages?

– Single-Shaft: Simple design, easy to operate. – Multiple-Shaft: Higher speed, better roll quality. – Turret: Fully automated, high productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Roll Rewinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Roll Rewinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Roll Rewinders share the responsibility of operating and maintaining machinery to convert steel bars into coils for various applications. Key job responsibilities include:

1. Machine Operation

Maintaining and operating rewinding machines to process steel bars.

- Setting up and adjusting machines to meet specific coil requirements.

- Monitoring machine performance and making necessary adjustments.

2. Material Handling

Loading and unloading steel bars and coils from machines.

- Using forklifts or overhead cranes to safely handle materials.

- Ensuring proper storage and organization of materials.

3. Quality Control

Inspecting and measuring coils to ensure they meet quality standards.

- Identifying and correcting any defects or inconsistencies.

- Maintaining a record of quality checks.

4. Maintenance and Troubleshooting

Performing routine maintenance tasks on machines.

- Identifying and resolving minor mechanical or electrical issues.

- Notifying supervisors of any major issues that require professional repair.

Interview Tips

To prepare for a Mill Roll Rewinder interview, you can follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, mission, and operations. Understand the specific requirements of the Mill Roll Rewinder role.

- Visit the company website for information on their products and services.

- Read industry publications and news articles to stay updated on relevant topics.

2. Highlight Relevant Experience

Emphasize your past experience operating and maintaining machinery. Showcase your skills in material handling, quality control, and troubleshooting.

- Quantify your accomplishments using specific numbers and metrics.

- Provide examples of how you have successfully resolved technical issues in a production environment.

3. Demonstrate Safety Awareness

Rewinders must follow strict safety protocols. Discuss your understanding of the potential hazards and your commitment to maintaining a safe work environment.

- Explain your experience with safety regulations and training.

- Highlight your ability to identify and mitigate risks.

4. Show Attention to Detail

Accuracy is crucial in this role. Emphasize your attention to detail and ability to follow instructions precisely.

- Describe your approach to quality control and how you ensure accuracy in your work.

- Share examples of how you have identified and corrected errors in a fast-paced production environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mill Roll Rewinder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.