Are you gearing up for an interview for a Mill Turner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mill Turner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

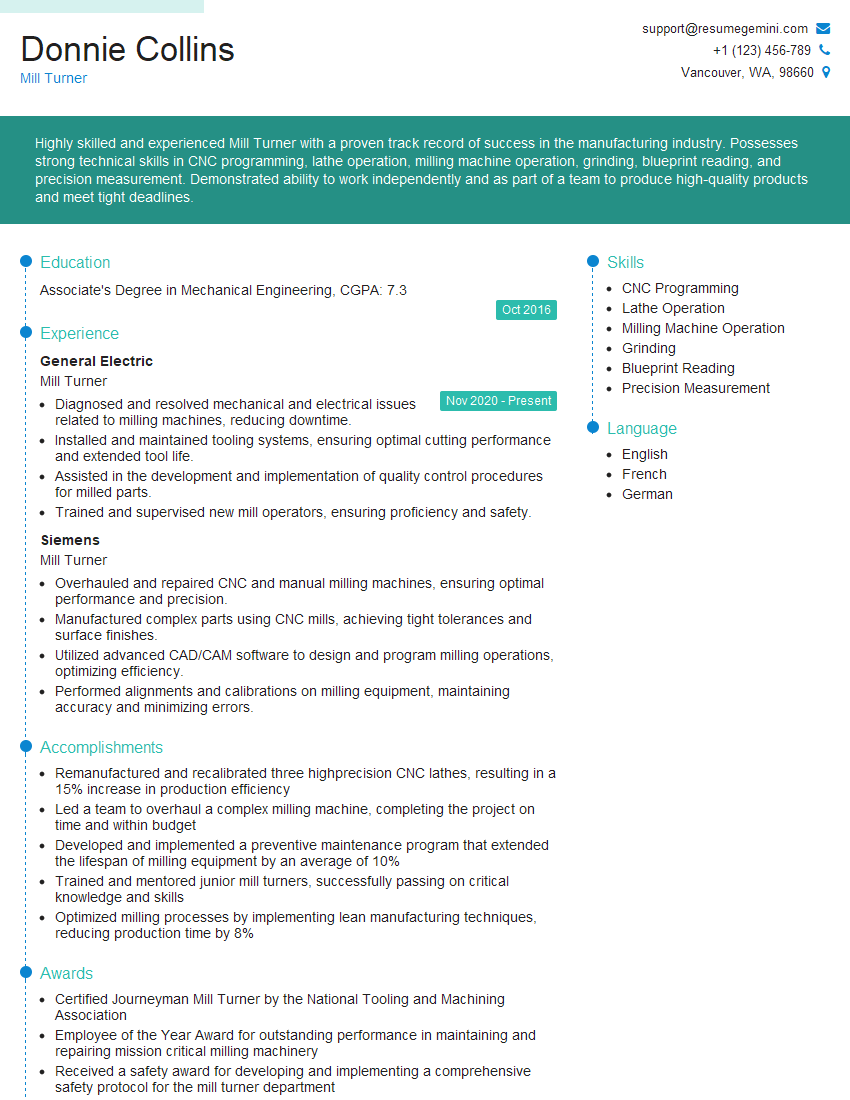

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Turner

1. Explain the process of setting up a milling machine for a specific job.

- Secure the workpiece to the machine table using clamps or a vise.

- Select the appropriate cutting tool and install it in the spindle.

- Set the spindle speed and feed rate according to the workpiece material and cutting tool.

- Adjust the depth of cut and the tool path using the machine’s controls.

- Run a test cut to ensure that the settings are correct before proceeding with the actual job.

2. Describe the different types of milling operations and the applications for each.

Surface milling

- Used to create flat surfaces on workpieces.

- Can be performed with a variety of cutting tools, including end mills, face mills, and fly cutters.

Contour milling

- Used to cut complex shapes into workpieces.

- Requires a special type of milling machine called a CNC (Computer Numerical Control) mill.

Thread milling

- Used to cut threads into workpieces.

- Requires a specialized cutting tool called a thread mill.

3. What are the factors that affect the cutting force in milling?

- Workpiece material

- Cutting tool material

- Spindle speed

- Feed rate

- Depth of cut

4. What are the safety precautions that must be observed when operating a milling machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris.

- Never operate the machine with loose clothing or jewelry.

- Be aware of the location of the machine’s emergency stop button.

- Follow all manufacturer’s instructions for safe operation.

5. What is the purpose of coolant in milling?

- To lubricate the cutting tool and workpiece

- To reduce friction and heat

- To remove chips and debris from the cutting zone

6. How do you calculate the spindle speed for milling?

- Determine the desired surface speed (SFM) for the cutting tool.

- Measure the diameter of the cutting tool (D) in inches.

- Use the formula: Spindle Speed (RPM) = SFM / (3.14 * D)

7. What are the different types of milling machines?

- Horizontal milling machine

- Vertical milling machine

- Bridgeport milling machine

- CNC milling machine

8. What is the difference between a mill and a lathe?

- A mill uses a rotating cutting tool to remove material from a workpiece.

- A lathe uses a stationary cutting tool to remove material from a rotating workpiece.

9. What is the most common type of milling operation?

- Surface milling

10. What is the most important thing to consider when selecting a milling cutter?

- The material being milled

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Turners are skilled professionals responsible for setting up, operating, and maintaining precision machines in various industries. Their primary duties involve:

1. Machine Operation

Operate CNC (Computer Numerical Control) and manual milling machines.

- Program and control machines according to specifications.

- Monitor machine operations and make adjustments as needed.

2. Tooling and Setup

Select and install appropriate cutting tools.

- Set up and adjust machine settings for precision cutting.

- Inspect and align machine components.

3. Inspection and Quality Control

Inspect finished parts against blueprints and specifications.

- Use precision measuring tools to ensure accuracy.

- Identify and correct any deviations from specifications.

4. Troubleshooting and Preventive Maintenance

Identify and resolve machine issues.

- Perform scheduled preventive maintenance to optimize machine performance.

- Lubricate and clean machine components.

Interview Tips

Preparing thoroughly for a Mill Turner interview will significantly enhance your chances of success. Here are some tips to help you ace it:

1. Research the Company and Position

Read the company’s website, LinkedIn page, and industry-related articles. This will give you a good understanding of their products, services, culture, and the specific requirements for the Mill Turner position.

- Tailor your answers to the company’s specific needs and the role responsibilities.

2. Practice Your Answers

Brainstorm common interview questions and prepare concise and clear answers that highlight your skills and experience. Remember to use the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

- Consider questions about your technical expertise, problem-solving abilities, and attention to detail.

3. Showcase Your Technical Knowledge

Mill Turners require a deep understanding of CNC programming, machine tools, and precision measurement. During the interview, be prepared to discuss your proficiency in these areas and provide examples of your hands-on experience.

- Highlight any certifications or training you have related to CNC operation or machining.

4. Emphasize Your Problem-Solving Skills

Mill Turners often encounter challenges during machine operation. In the interview, emphasize your ability to identify and resolve problems efficiently. Share examples where you successfully diagnosed and fixed machine issues.

- Use specific instances to demonstrate your analytical thinking, troubleshooting skills, and ability to work under pressure.

5. Highlight Your Attention to Detail

Precision is paramount for Mill Turners. In the interview, highlight your meticulous attention to detail and your ability to work within tight tolerances. Provide examples where you exceeded specifications or identified and corrected errors.

- Explain how your commitment to accuracy ensures the production of high-quality parts.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mill Turner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.