Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Miller Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

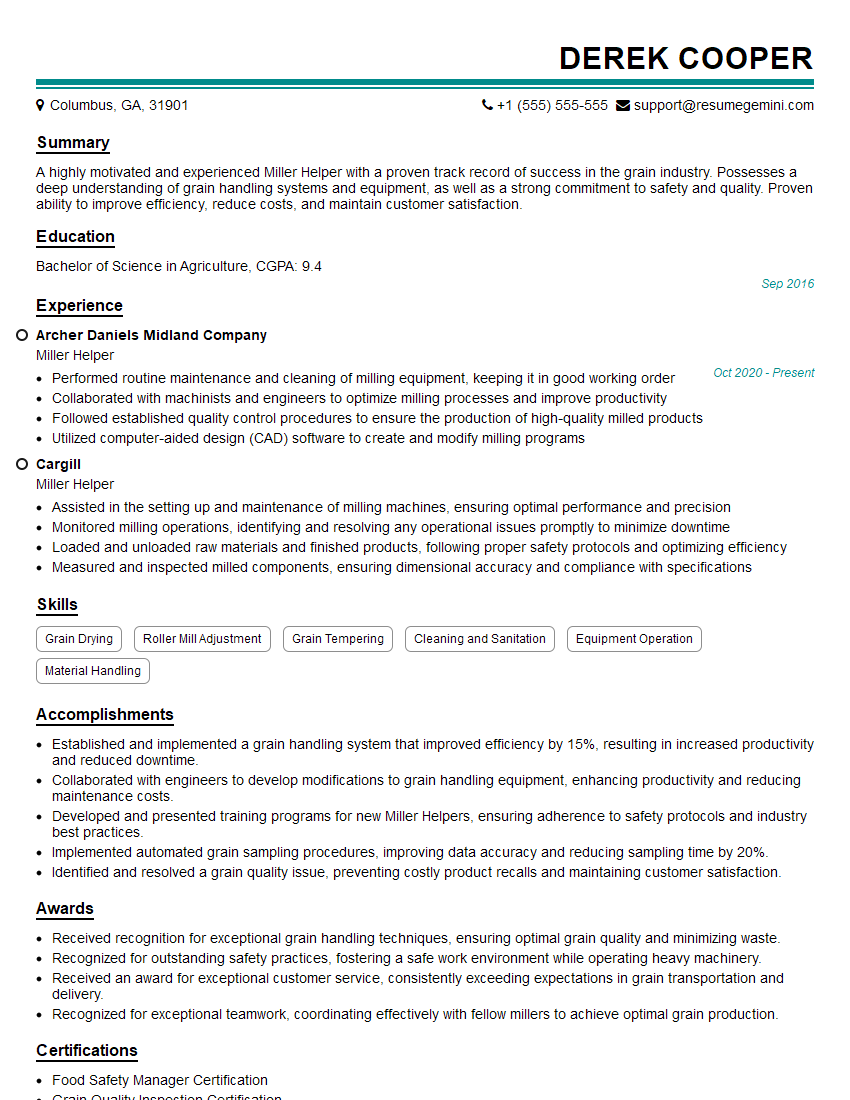

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Miller Helper

1. Why did you apply for this position of Miller Helper?

– Demonstrated interest and passion for the industry. – Highlighted specific skills and experiences that align with the job’s requirements. – Expressed eagerness to learn and contribute to the company’s success.

2. Can you explain the process of setting up and maintaining milling equipment?

Setup

- Inspect equipment for any damage or defects.

- Assemble and install the milling machine according to manufacturer’s instructions.

- Configure settings such as feed rate, cutting speed, and depth of cut.

Maintenance

- Lubricate and clean equipment regularly.

- Inspect and replace worn or damaged parts.

- Calibrate equipment for accuracy and efficiency.

3. What is your experience with operating CNC milling machines?

– Described proficiency in operating various CNC milling machines. – Explained familiarity with different types of cutting tools and their applications. – Emphasized understanding of CNC programming and G-code commands.

4. How do you handle complex milling operations that require precision and accuracy?

– Outlined a methodical approach for planning and executing complex milling operations. – Discussed techniques for optimizing tool paths and ensuring workpiece accuracy. – Explained the importance of regular calibration and maintenance to maintain machine precision.

5. How do you ensure the quality of milled parts?

– Described inspection and verification procedures to ensure parts meet specifications. – Explained the use of calipers, micrometers, and other measuring tools. – Emphasized the importance of documentation and record-keeping for quality control.

6. What is your experience with different types of materials used in milling?

– Demonstrated knowledge of the properties and machining characteristics of different materials. – Explained how to adjust cutting parameters and tooling to optimize milling results for each material. – Discussed experience with specialized materials or alloys used in specific industries.

7. How do you stay up-to-date with the latest advancements in milling technology?

– Mentioned attending industry conferences, workshops, or training programs. – Discussed reading technical journals, articles, or whitepapers. – Expressed an eagerness to learn and embrace new technologies that enhance efficiency or quality.

8. How do you handle unexpected downtime or equipment malfunctions?

– Outlined a troubleshooting process for identifying and resolving common problems. – Explained the importance of preventative maintenance to minimize downtime. – Discussed the use of diagnostic tools and reference materials for troubleshooting.

9. How do you prioritize multiple tasks and manage your time effectively?

– Explained the use of scheduling techniques and prioritization methods. – Discussed the ability to work independently and as part of a team. – Emphasized the importance of clear communication and delegation to streamline workflow.

10. What are your strengths and weaknesses as a Miller Helper?

Strengths

- Strong technical skills in milling operations.

- Excellent attention to detail and precision.

- Proficient in operating CNC milling machines.

Weaknesses

- Limited experience in a high-volume production environment.

- Looking to further develop my knowledge of advanced milling techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Miller Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Miller Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Miller Helper plays a crucial role in supporting the Miller in a milling operation. Their key responsibilities include:

1. Loading and Unloading Grain

Loading raw grain into the mill and unloading processed products from storage bins.

2. Maintaining Equipment

Performing basic maintenance tasks on milling equipment, such as cleaning, lubrication, and minor repairs.

3. Monitoring Process

Monitoring milling processes and ensuring optimal flow and output.

4. Assisting in Product Development

Assisting the Miller in developing and testing new products.

5. Cleaning and Sanitation

Maintaining a clean and sanitary work environment in accordance with safety regulations.

Interview Tips

Preparing thoroughly for a Miller Helper interview is essential to showcase your skills and make a positive impression. Here are some interview tips to help you ace:

1. Research the Company and Position

Gather information about the milling company and the specific role you are applying for. Understand their products, processes, and industry trends.

2. Highlight Relevant Skills

Emphasize your physical strength, ability to work in a fast-paced environment, and attention to detail. Share examples of your experience with grain handling, equipment maintenance, and quality control.

3. Demonstrate Work Ethic and Motivation

Convey your willingness to work hard and learn new skills. Showcase your commitment to safety and adherence to industry regulations.

4. Practice Common Interview Questions

Prepare answers to common interview questions, such as: “Tell us about your experience in the milling industry,” “What is your understanding of the role of a Miller Helper,” and “How do you handle physically demanding tasks?”

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and company. Prepare questions about the company’s growth plans, sustainability initiatives, or opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Miller Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!