Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milling Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

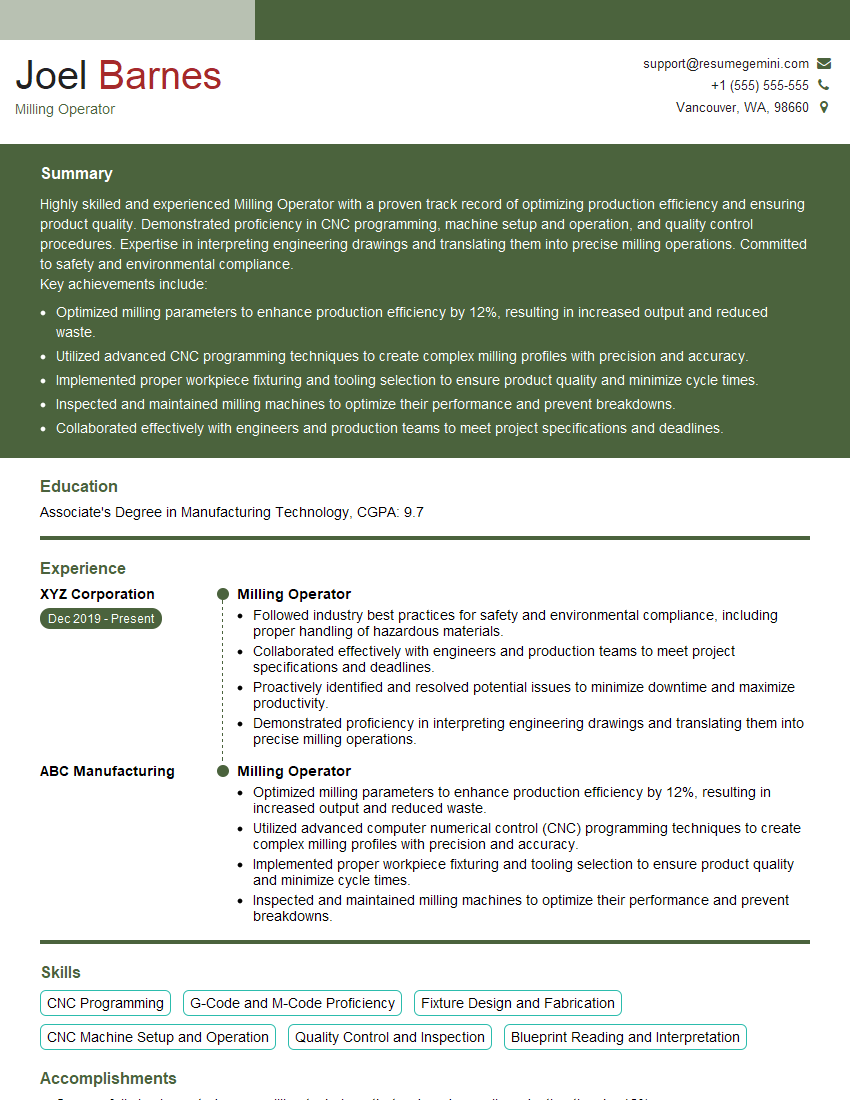

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milling Operator

1. Describe the role of a Milling Operator in general?

A Milling Operator is responsible for operating milling machines to cut, drill, and shape metal parts according to specifications. Key duties include:

- Reading and interpreting blueprints and instructions.

- Setting up and operating milling machines.

- Performing calculations to determine tool settings and feed rates.

- Monitoring the milling process and making adjustments as needed.

- Inspecting finished parts to ensure they meet specifications.

2. Explain the different types of milling machines and their uses?

CNC Milling Machines

- Computer-controlled machines that offer high precision and accuracy.

- Used for complex parts and mass production.

Manual Milling Machines

- Operated manually, requiring skilled operators.

- Suitable for low-volume production and prototyping.

Bridgeport Milling Machines

- Versatile machines with a movable table and spindle head.

- Used for a wide range of milling operations, including drilling, boring, and shaping.

3. What are the safety precautions that must be observed when operating a milling machine?

- Wear proper safety gear, including eye protection, gloves, and earplugs.

- Ensure the machine is properly grounded and maintained.

- Clear the work area of any debris or obstacles.

- Secure the workpiece firmly to prevent movement during operation.

- Keep hands away from rotating tools and moving parts.

- Never leave the machine unattended while running.

4. How do you calculate the cutting speed and feed rate for a milling operation?

- Cutting Speed (SFM): SF = (RPM * π * D) / 4, where RPM is spindle speed, π is 3.14, and D is tool diameter.

- Feed Rate (FPR): FPR = (SF * T) / N, where SF is cutting speed, T is tooth count, and N is number of teeth in contact.

5. What is the difference between climb milling and conventional milling?

Climb milling:

- The cutter’s teeth engage with the workpiece while moving in the same direction as the feed.

- Produces a better surface finish but can create more chatter.

Conventional milling:

- The cutter’s teeth engage with the workpiece while moving in the opposite direction of the feed.

- Produces less chatter but can result in a rougher surface finish.

6. Explain the purpose of coolant in milling operations?

- Lubricates the cutting tool and workpiece, reducing friction and heat.

- Removes chips and debris from the cutting zone, improving surface finish.

- Protects the tool and workpiece from damage by reducing wear and stress.

7. What are the common types of milling cutters and their applications?

- End Mills: General-purpose cutters for various operations, including profiling, pocketing, and slot cutting.

- Face Mills: Used for surfacing and finishing operations on flat surfaces.

- Ball Nose Cutters: Suitable for contour milling and creating rounded surfaces.

- Slot Cutters: Specifically designed for cutting slots and keyways.

- Thread Mills: Used for creating internal and external threads.

8. How do you troubleshoot common problems encountered in milling operations?

- Chatter: Ensure proper tool selection, feed rate, and cutter sharpness.

- Poor Surface Finish: Check tool wear, coolant flow, and feed rate.

- Tool Breakage: Verify tool quality, proper setup, and workpiece material.

- Dimensional Inaccuracy: Recalibrate the machine, check cutter dimensions, and ensure the workpiece is properly secured.

- Machine Vibration: Inspect the machine for loose components, misalignment, or unbalanced tools.

9. What quality control measures are important in milling operations?

- Regular machine calibration to ensure accuracy.

- Inspection of raw materials and finished parts.

- Use of measuring tools and gauges to verify dimensions.

- Adherence to established quality standards and procedures.

10. Describe the importance of maintenance and preventive care for milling machines?

- Regular lubrication and cleaning to prevent wear and tear.

- Inspection and replacement of worn parts to ensure optimal performance.

- Monitoring of machine parameters to identify potential issues early on.

- Scheduled maintenance to minimize downtime and maximize machine life.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milling Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milling Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Milling Operators play a crucial role in manufacturing processes by operating and maintaining milling machines to produce high-quality finished products.

1. Machine Operation and Maintenance

Operate a variety of milling machines, including manual, CNC, and vertical/horizontal machines, to create complex shapes and parts from raw materials.

- Set up and adjust machine parameters, including speed, feed rate, and cutting depth, based on production specifications.

- Monitor machine operation, inspect finished parts for accuracy and dimensions, and make adjustments as needed.

- Perform routine maintenance on milling machines, including cleaning, lubrication, and minor repairs.

2. Material Handling and Setup

Load and unload raw materials, such as metal stock, plastic sheets, or wood, into the milling machine.

- Secure and align materials on the worktable using fixtures and clamps to ensure proper cutting and sizing.

- Follow work orders and drawings to determine the correct cutting tools and techniques for the job.

3. Quality Control and Inspection

Inspect finished parts using measuring tools and gauges to ensure they meet specifications for dimensions, tolerances, and surface finish.

- Identify and correct any deviations from specifications using appropriate tools and techniques.

- Maintain records of inspection results for quality assurance purposes.

4. Safety and Compliance

Follow all safety protocols and guidelines related to milling machine operation.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Adhere to established procedures for hazardous materials handling and disposal.

- Maintain a clean and organized work area to prevent accidents and ensure machine efficiency.

Interview Tips

Preparing thoroughly for a Milling Operator interview can significantly increase your chances of success. Here are some helpful tips and strategies to guide you:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Visit their website and social media pages to gather information about their culture, values, and recent accomplishments.

- Thoroughly review the job posting to understand the specific requirements, responsibilities, and qualifications expected of a Milling Operator.

- Identify the key skills and experiences that the employer is seeking, and highlight them in your resume and during the interview.

2. Practice Common Interview Questions

Anticipate potential interview questions and prepare thoughtful responses that demonstrate your knowledge, skills, and fit for the role.

- Describe your experience in operating different types of milling machines, including manual, CNC, and vertical/horizontal models.

- Explain your knowledge of machine setup, cutting tool selection, and material handling techniques.

- Discuss your quality control procedures and experience in inspecting milled parts for accuracy and conformance to specifications.

- Share examples of your ability to work independently and as part of a team in a manufacturing environment.

3. Emphasize Your Safety Awareness

Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment:

- Describe your experience in wearing and properly using personal protective equipment (PPE).

- Explain your knowledge of hazardous materials handling and disposal procedures.

- Discuss your attention to detail and your ability to identify and mitigate potential hazards in the workplace.

4. Be Professional and Enthusiastic

Present yourself professionally throughout the interview process, from your attire to your demeanor. Be enthusiastic about the opportunity to work as a Milling Operator and express your interest in contributing to the company’s success.

- Arrive on time for the interview and dress appropriately for the occasion.

- Be polite and respectful to the interviewer and show interest in the company and the position.

- Maintain eye contact, speak clearly, and actively listen during the interview.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position:

- Inquire about the company’s commitment to safety and the measures they have in place to protect employees.

- Ask about opportunities for professional development and advancement within the organization.

- Seek information about the company’s vision for the future and how your skills and experience can contribute to their goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Milling Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!