Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Millwright Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

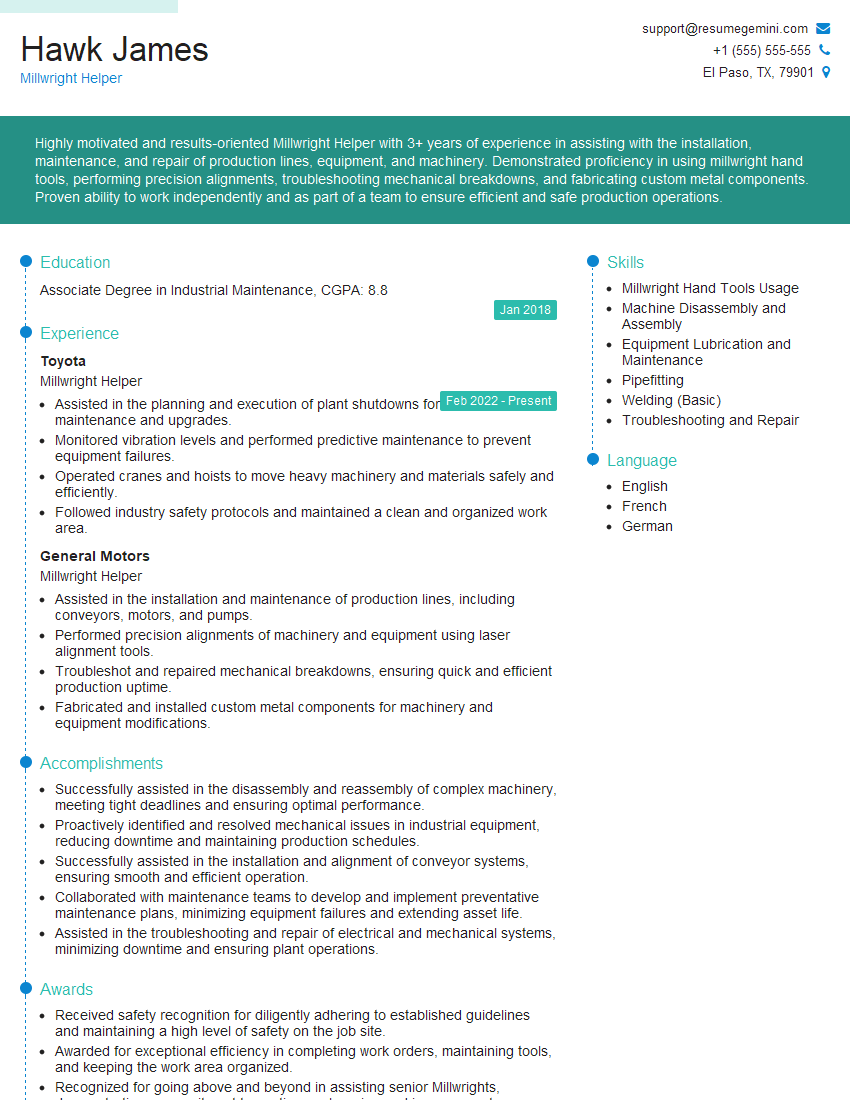

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Millwright Helper

1. Explain the process of aligning a shaft using dial indicators?

Sample Answer:

- Mount dial indicators on the shaft in both the horizontal and vertical planes.

- Rotate the shaft and observe the dial indicator readings.

- Adjust the shaft position until the dial indicator readings are zero in both planes.

- Lock the shaft in place once it is aligned.

2. What are the different types of bearings used in industrial machinery, and what are their advantages and disadvantages?

Types, Advantages, and Disadvantages of Bearings

- Rolling element bearings: These bearings use balls or rollers to reduce friction between moving parts. They are durable, efficient, and can handle high loads. However, they are also more expensive than other types of bearings.

- Plain bearings: These bearings use a sliding surface to reduce friction. They are less expensive than rolling element bearings, but they are also less durable and efficient.

- Hydrodynamic bearings: These bearings use a film of oil to separate moving parts. They are very efficient and can handle high loads. However, they are also more complex and expensive than other types of bearings.

3. What is the purpose of a coupling, and what are the different types of couplings used in industrial machinery?

Sample Answer:

- Purpose: A coupling is a device that connects two shafts and transmits power from one shaft to another.

- Types: There are many different types of couplings, each with its own advantages and disadvantages. Some common types include:

- Flexible couplings

- Rigid couplings

- Gear couplings

- Chain couplings

4. What is the difference between a hydraulic system and a pneumatic system?

Sample Answer:

- Hydraulic system: Uses fluid (oil) to transmit power.

- Pneumatic system: Uses air to transmit power.

- Hydraulic systems:

- More powerful than pneumatic systems

- Can handle higher pressures

- More efficient than pneumatic systems

- Pneumatic systems:

- Less expensive to install and maintain

- Safer to operate than hydraulic systems

- More compact than hydraulic systems

5. What is the purpose of a gearbox, and what are the different types of gearboxes used in industrial machinery?

Sample Answer:

- Purpose: A gearbox is a device that changes the speed and torque of a rotating shaft.

- Types: There are many different types of gearboxes, each with its own advantages and disadvantages. Some common types include:

- Spur gearboxes

- Helical gearboxes

- Bevel gearboxes

- Worm gearboxes

6. What are the different types of welding processes, and what are the advantages and disadvantages of each?

Types, Advantages, and Disadvantages of Welding Processes

- Arc welding: Uses an electric arc to melt the metal and fuse it together.

- MIG welding: A type of arc welding that uses a shielding gas to protect the weld from contamination.

- TIG welding: Also known as GTAW. A type of arc welding that uses a tungsten electrode and a shielding gas to protect the weld from contamination.

- Stick welding: Also known as MMA welding. A type of arc welding that uses a coated electrode.

- Gas welding: Uses a flame to melt the metal and fuse it together.

7. What are the different types of lubricants used in industrial machinery, and what are their advantages and disadvantages?

Types, Advantages, and Disadvantages of Lubricants

- Oil: A liquid lubricant that is used to reduce friction between moving parts.

- Grease: A semi-solid lubricant that is used to reduce friction between moving parts.

- Solid lubricants: A dry lubricant that is used to reduce friction between moving parts.

- Advantages of oil:

- Excellent cooling properties

- Can handle high loads

- Easy to apply

- Advantages of grease:

- Stays in place longer than oil

- Can be used in high-temperature applications

- Protects metal surfaces from corrosion

- Advantages of solid lubricants:

- Can be used in extreme temperatures

- Do not attract dirt and dust

- Can be used in clean environments

8. What are the safety precautions that must be taken when working on industrial machinery?

Sample Answer:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Lock out and tag out machinery before performing any maintenance or repairs.

- Be aware of the potential hazards of the machinery, including moving parts and electrical hazards.

- Follow all safety procedures and guidelines.

- Never work on machinery alone.

9. What are the different types of maintenance tasks that are performed on industrial machinery?

Sample Answer:

- Preventive maintenance: Tasks that are performed on a regular basis to prevent breakdowns.

- Predictive maintenance: Tasks that are performed to identify and correct potential problems before they cause breakdowns.

- Corrective maintenance: Tasks that are performed to repair breakdowns.

- Overhaul: Tasks that are performed to restore machinery to its original condition.

10. What are the different types of tools that are used by millwright helpers?

Sample Answer:

- Hand tools

- Power tools

- Measuring tools

- Lubrication tools

- Welding tools

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Millwright Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Millwright Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Millwright Helpers play a crucial role in supporting Millwrights in the maintenance, repair, and installation of machinery and equipment within industrial facilities.

1. Assist with Equipment Maintenance and Repair

Millwright Helpers aid Millwrights with various maintenance and repair tasks, including:

- Disassembling and reassembling machinery

- Performing minor repairs and adjustments

2. Assist with Equipment Installation

Millwright Helpers assist Millwrights during equipment installation and relocation projects, such as:

- Preparing equipment for installation

- Setting up tools and materials

- Aligning and leveling machinery

3. Perform Routine Inspections

Millwright Helpers conduct routine inspections of equipment to identify potential issues and ensure smooth operation, including:

- Checking for leaks, vibrations, and unusual noises

- Reporting any discrepancies to Millwrights

4. Other Duties

Millwright Helpers may also perform other duties as assigned, such as:

- Cleaning and maintaining work areas

- Loading and unloading materials

Interview Tips

1. Research the Company and Role

Thoroughly research the company’s history, values, and current projects to demonstrate your interest and understanding of the industry.

2. Highlight Relevant Experience

Emphasize your experience in mechanical work, tool handling, and following instructions. If you have experience in a similar role, be sure to highlight your contributions.

3. Be Prepared to Discuss Safety

Safety is paramount in industrial settings. Explain your understanding of safety protocols and your commitment to following them meticulously.

4. Show a Willingness to Learn

Millwright Helpers are expected to learn from experienced Millwrights. Express your enthusiasm for learning new skills and your commitment to professional development.

5. Prepare Questions

Asking thoughtful questions demonstrates your interest and curiosity. Prepare questions about the company’s operations, the role’s expectations, and opportunities for advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Millwright Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Millwright Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.