Are you gearing up for a career in Millwright Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Millwright Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

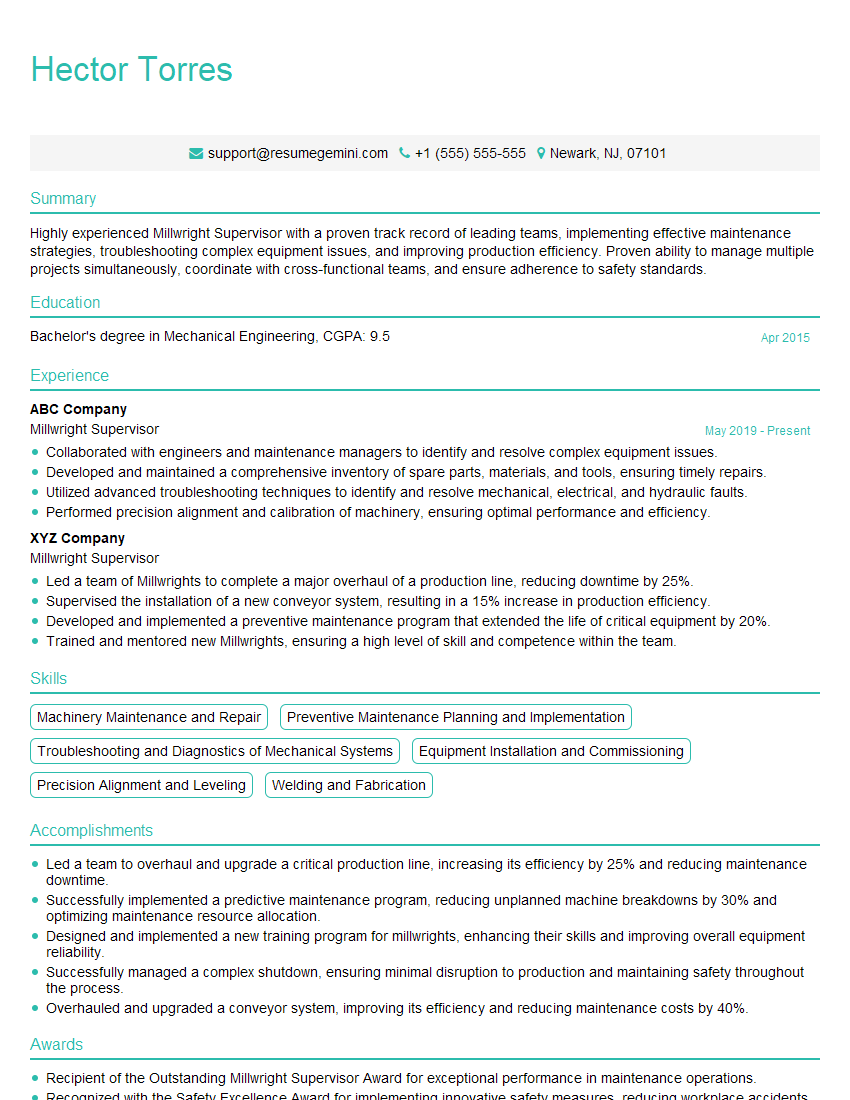

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Millwright Supervisor

1. What are the key responsibilities of a Millwright Supervisor?

As a Millwright Supervisor, I would be responsible for overseeing the activities of Millwrights, ensuring the efficient operation and maintenance of machinery, equipment, and systems within the plant. My key responsibilities would include:

- Plan, organize, direct, and control the work of Millwrights

- Establish and maintain high standards of safety and quality

- Monitor and evaluate the performance of Millwrights

- Identify and resolve equipment problems

- Coordinate with other departments to ensure smooth operation

2. Describe the steps involved in aligning a motor and pump

Shaft Alignment

- Mount the motor and pump on a rigid base

- Use a dial indicator to measure the misalignment

- Adjust the motor or pump until the misalignment is within acceptable limits

Coupling Alignment

- Ensure that the shafts of the motor and pump are parallel

- Use a straight edge or laser to align the couplings

- Tighten the coupling bolts according to the manufacturer’s specifications

3. How would you troubleshoot a problem with a conveyor belt that is not moving?

I would troubleshoot a problem with a conveyor belt that is not moving by following these steps:

- Check the power supply to the conveyor belt

- Check the motor and gearbox for any damage

- Check the belts for any damage or wear

- Check the pulleys for any misalignment

- Check the sensors for any problems

4. What are the different types of lubricants used in industrial machinery?

The different types of lubricants used in industrial machinery include:

- Oils

- Greases

- Solid lubricants

- Gases

The type of lubricant used depends on the specific application and the requirements of the machinery.

5. How would you develop a preventive maintenance plan for a fleet of forklifts?

To develop a preventive maintenance plan for a fleet of forklifts, I would:

- Identify the critical components of the forklifts

- Determine the frequency of maintenance for each component

- Develop a schedule for preventive maintenance

- Train the maintenance staff on the preventive maintenance procedures

- Monitor the effectiveness of the preventive maintenance plan

6. What are the safety precautions that should be taken when working with rotating machinery?

The safety precautions that should be taken when working with rotating machinery include:

- Wear appropriate safety gear, such as gloves, eye protection, and hearing protection

- Lock out and tag out the machinery before performing any maintenance or repairs

- Keep a safe distance from rotating parts

- Be aware of the potential hazards, such as pinch points and shear points

7. How would you motivate a team of Millwrights to achieve high performance?

I would motivate a team of Millwrights to achieve high performance by:

- Setting clear goals and expectations

- Providing regular feedback and recognition

- Creating a positive and supportive work environment

- Empowering the team to make decisions

- Celebrating successes

8. What are the latest trends in millwrighting and maintenance?

Some of the latest trends in millwrighting and maintenance include:

- The use of predictive maintenance technologies

- The adoption of digital twins

- The use of augmented reality and virtual reality in training and maintenance

- The increasing use of robotics and automation

9. How would you stay up-to-date on the latest millwrighting and maintenance techniques?

I would stay up-to-date on the latest millwrighting and maintenance techniques by:

- Attending industry conferences and workshops

- Reading industry publications and white papers

- Taking online courses and training programs

- Networking with other millwrights and maintenance professionals

10. What are your career goals?

My career goals are to:

- Continue to develop my skills and knowledge in millwrighting and maintenance

- Advance to a leadership position in millwrighting or maintenance

- Make a significant contribution to the maintenance and reliability of industrial machinery

- Help to improve the safety and efficiency of industrial operations

- Mentor and develop the next generation of millwrights and maintenance professionals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Millwright Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Millwright Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Millwright Supervisors are responsible for overseeing the work of millwrights, ensuring that all projects are completed safely and efficiently. They also play a key role in maintaining and repairing the plant’s machinery and equipment.

1. Planning and Scheduling

Millwright Supervisors are responsible for planning and scheduling all millwright work. This includes developing work schedules, assigning tasks to millwrights, and coordinating with other departments to ensure that all work is completed on time.

- Develop and implement work schedules that meet production goals.

- Assign tasks to millwrights based on their skills and experience.

- Coordinate with other departments to ensure that all work is completed on time and within budget.

2. Safety Management

Millwright Supervisors are responsible for ensuring that all millwright work is completed safely. This includes developing and implementing safety procedures, providing safety training to millwrights, and monitoring the work environment for potential hazards.

- Develop and implement safety procedures that meet all applicable regulations.

- Provide safety training to millwrights on a regular basis.

- Monitor the work environment for potential hazards and take corrective action as needed.

3. Equipment Maintenance and Repair

Millwright Supervisors are responsible for maintaining and repairing the plant’s machinery and equipment. This includes conducting regular inspections, diagnosing problems, and making repairs. They also work with other departments to ensure that all equipment is operating properly.

- Conduct regular inspections of all machinery and equipment.

- Diagnose problems and make repairs to machinery and equipment.

- Work with other departments to ensure that all equipment is operating properly.

4. Training and Development

Millwright Supervisors are responsible for training and developing millwrights. This includes providing on-the-job training, conducting formal training sessions, and mentoring millwrights. They also work with other departments to ensure that millwrights have the skills and knowledge they need to perform their jobs effectively.

- Provide on-the-job training to millwrights.

- Conduct formal training sessions on a regular basis.

- Mentor millwrights and help them develop their skills and knowledge.

Interview Tips

Preparing for a millwright supervisor interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before your interview, take some time to research the company and the specific millwright supervisor position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the position you are applying for.

- Visit the company’s website and social media pages.

- Read articles about the company in industry publications.

- Talk to people you know who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked in a millwright supervisor interview. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with planning and scheduling millwright work?

- How do you ensure that all millwright work is completed safely?

- What is your experience with maintaining and repairing machinery and equipment?

- How do you train and develop millwrights?

3. Be prepared to ask questions

Asking questions at the end of an interview shows that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

- What are the biggest challenges facing the millwright department?

- What are the company’s goals for the next year?

- What is the company’s culture like?

- What is the next step in the interview process?

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Arrive for your interview 10-15 minutes early.

5. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be yourself and don’t try to be someone you’re not.

- Make eye contact, smile, and speak clearly.

- Be confident in your abilities and your experience.

Next Step:

Now that you’re armed with the knowledge of Millwright Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Millwright Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini