Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mine Cutting and Channeling Machine Coal Miner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mine Cutting and Channeling Machine Coal Miner so you can tailor your answers to impress potential employers.

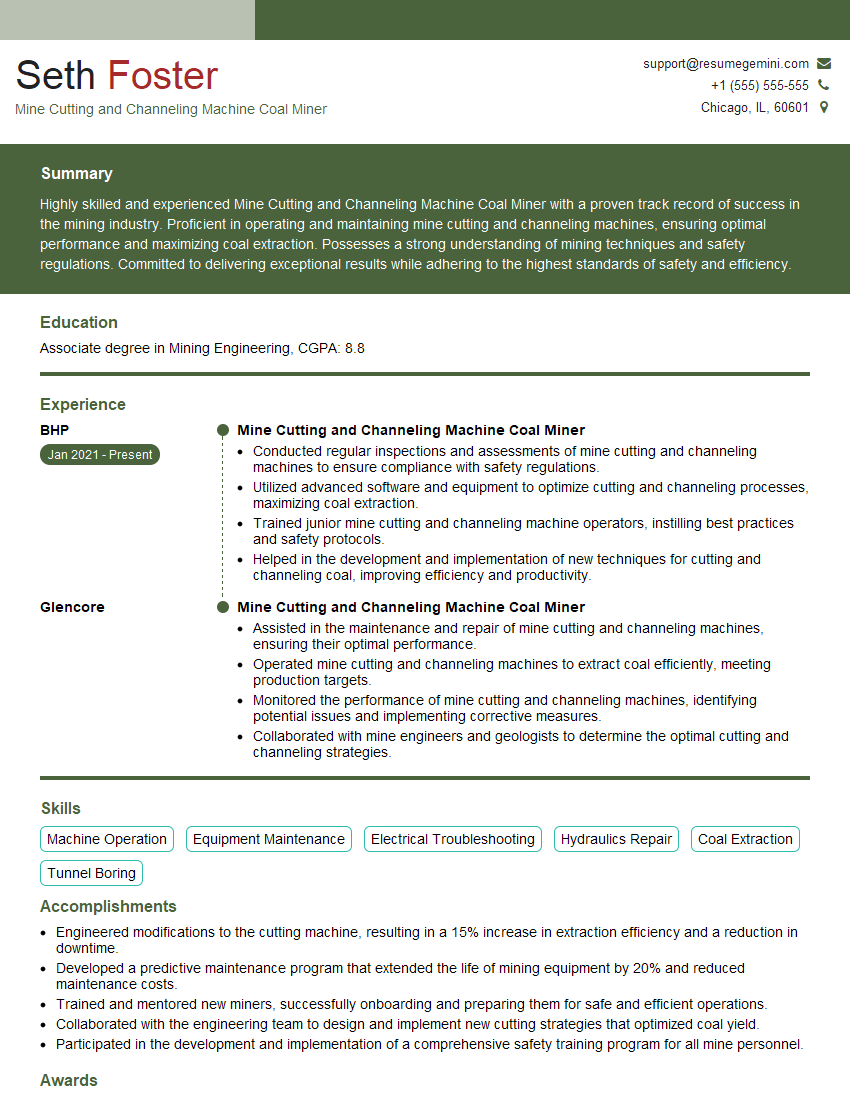

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mine Cutting and Channeling Machine Coal Miner

1. What are the key responsibilities of a Mine Cutting and Channeling Machine Coal Miner?

As a highly-skilled Mine Cutting and Channeling Machine Coal Miner, I am responsible for:

- Operating and maintaining mine cutting and channeling machines to extract coal from the mine site.

- Ensuring the safety of self, colleagues, and equipment during cutting and channeling operations.

- Understanding and following all safety regulations and guidelines established for the mine environment.

- Inspecting and maintaining equipment to ensure optimal performance, including inspections of cutting heads, belts, and hydraulic systems.

- Monitoring coal production to ensure targets are met, while adhering to safety and efficiency standards.

- Collaborating with other team members to ensure smooth and coordinated operations within the mining site.

2. Explain the different types of cutting and channeling machines used in coal mining and their applications.

Types of Cutting Machines

- Continuous Miner: Employs a rotating drum with cutting bits to extract coal in a continuous operation, suitable for thick and medium-thick coal seams.

- Shearer: Utilizes a series of cutting picks mounted on a rotating chain to cut coal at the face, ideal for thin and undulating seams.

Types of Channeling Machines

- Roadheader: Used to create roadways and tunnels within the mine, featuring a rotating head equipped with cutting picks or discs.

- Plow: Consists of a blade or plow-shaped tool that cuts and channels coal from the seam, commonly employed in soft coal deposits.

3. Describe the steps involved in preparing and operating a mine cutting and channeling machine.

- Conduct a thorough pre-operational inspection of the machine, ensuring all components are functioning properly.

- Position the machine at the designated cutting or channeling location, ensuring stability and proper alignment.

- Calibrate and adjust the machine’s settings according to the specific coal seam characteristics and desired extraction parameters.

- Initiate the cutting or channeling process, closely monitoring machine performance and adjusting controls as needed.

- Remain vigilant during operation, observing for any potential hazards or equipment malfunctions.

4. How do you ensure the safety of yourself and others while operating a mine cutting and channeling machine?

- Adhere strictly to all established safety protocols and regulations for the mine environment.

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and hearing protection.

- Maintain a clear and organized work area, free from tripping hazards and potential obstructions.

- Be aware of the location of colleagues and communicate clearly to avoid any misunderstandings or potential accidents.

- Inspect the equipment regularly and report any identified issues promptly to ensure timely maintenance.

5. Explain the maintenance procedures for a mine cutting and channeling machine.

- Regularly clean and lubricate all moving parts to minimize wear and tear.

- Inspect and replace cutting heads, bits, and picks as needed to maintain optimal cutting efficiency.

- Monitor hydraulic systems for leaks and ensure proper fluid levels.

- Conduct electrical inspections to ensure wiring and connections are intact and secure.

- Follow manufacturer’s recommendations for scheduled maintenance and servicing to extend equipment lifespan.

6. Discuss the challenges you have faced as a Mine Cutting and Channeling Machine Coal Miner and how you overcame them.

- Encountering unexpected geological formations: Adapting cutting techniques and adjusting machine settings to navigate challenging rock conditions.

- Maintaining productivity in difficult mining environments: Optimizing cutting patterns and implementing strategies to minimize downtime due to equipment issues.

- Working in confined spaces: Employing proper ventilation techniques and maintaining clear communication with colleagues to ensure safety.

- Collaborating with a diverse team: Establishing effective communication channels and fostering a positive work environment to achieve shared goals.

- Responding to emergencies: Remaining calm under pressure and implementing appropriate safety protocols to mitigate risks.

7. Describe your experience in troubleshooting and resolving equipment malfunctions on a mine cutting and channeling machine.

- Identifying the source of the issue through systematic inspection and analysis.

- Utilizing technical knowledge and experience to determine the appropriate repair or replacement.

- Safely isolating the affected components and implementing proper lockout/tagout procedures.

- Performing repairs or replacements efficiently, ensuring minimal disruption to mining operations.

- Testing the repaired equipment thoroughly to verify its functionality and adherence to safety standards.

8. Explain how you stay up-to-date with advancements in mining technology and best practices.

- Attending industry conferences and workshops to learn about new techniques and equipment innovations.

- Reading technical publications and industry journals to stay informed about best practices and safety regulations.

- Engaging in discussions with colleagues and sharing knowledge to foster continuous improvement.

- Seeking opportunities for training and certification to enhance skills and demonstrate proficiency.

- Actively participating in professional organizations and staying connected with industry experts.

9. Describe your approach to ensuring a safe and productive mining environment.

- Maintaining a high level of situational awareness and adhering to all safety protocols.

- Working collaboratively with colleagues to identify and mitigate potential hazards.

- Communicating effectively to ensure clear understanding of tasks and responsibilities.

- Continuously striving to improve efficiency while prioritizing safety and maintaining quality.

- Promoting a positive and supportive work environment where individuals feel comfortable raising concerns or suggesting improvements.

10. Explain how you maintain high levels of motivation and focus in the demanding environment of a coal mine.

- Setting clear goals and regularly tracking progress to stay motivated and accountable.

- Finding purpose in the work by understanding the importance of coal mining for energy production and economic growth.

- Challenging myself with new tasks and responsibilities to maintain engagement and avoid monotony.

- Taking regular breaks and practicing mindfulness techniques to maintain focus and reduce stress.

- Seeking support and encouragement from colleagues and supervisors to overcome challenges and stay motivated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mine Cutting and Channeling Machine Coal Miner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mine Cutting and Channeling Machine Coal Miner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mine Cutting and Channeling Machine Coal Miners are responsible for operating heavy machinery to extract coal from underground mines. Their primary duties include:

1. Machine Operation

Skilled in operating and maintaining cutting and channeling machines, along with auxiliary equipment.

- Operate cutting machines to make horizontal or vertical cuts in coal seams.

- Use channeling machines to create channels or grooves in coal seams, facilitating coal extraction.

2. Coal Extraction

Efficiently extract coal from underground mines, ensuring safety and productivity.

- Position and maneuver machines to maximize coal extraction.

- Monitor coal extraction process, adjusting machine settings as needed.

3. Mine Environment Maintenance

Contribute to a safe and productive work environment, adhering to safety regulations and maintaining machinery.

- Maintain a clean and organized work area.

- Inspect and maintain equipment to ensure proper functioning.

4. Safety Compliance

Prioritize safety in all aspects of the job, adhering to established safety protocols and regulations.

- Wear appropriate safety gear and follow safety procedures.

- Report any safety hazards or concerns to supervisors.

Interview Tips

Preparing for an interview as a Mine Cutting and Channeling Machine Coal Miner requires thorough preparation and a clear understanding of the job’s responsibilities. Here are some interview tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the mining company, its operations, and the specific role you are applying for. Understand the industry trends and challenges to demonstrate your knowledge and interest.

- Visit the company website and study their mission, values, and recent news.

- Read industry publications and articles to stay informed about current developments.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize skills and experience directly relevant to the job description. Quantify your accomplishments and provide specific examples to showcase your capabilities.

- Highlight your expertise in operating cutting and channeling machines.

- Provide examples of how you have successfully extracted coal in underground mines.

3. Demonstrate Safety Consciousness

Emphasize your commitment to safety and your knowledge of safety protocols. Explain how you prioritize safety in your work and how you have contributed to a safe work environment in previous roles.

- Describe your experience with safety training and certifications.

- Share examples of how you have identified and mitigated safety hazards.

4. Prepare for Technical Questions

Expect technical questions related to mining operations, equipment maintenance, and safety procedures. Review common mining terminology and concepts to demonstrate your technical proficiency.

- Practice answering questions about different types of cutting and channeling machines and their applications.

- Be prepared to discuss troubleshooting techniques and equipment repair procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mine Cutting and Channeling Machine Coal Miner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!