Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mine Cutting and Channeling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

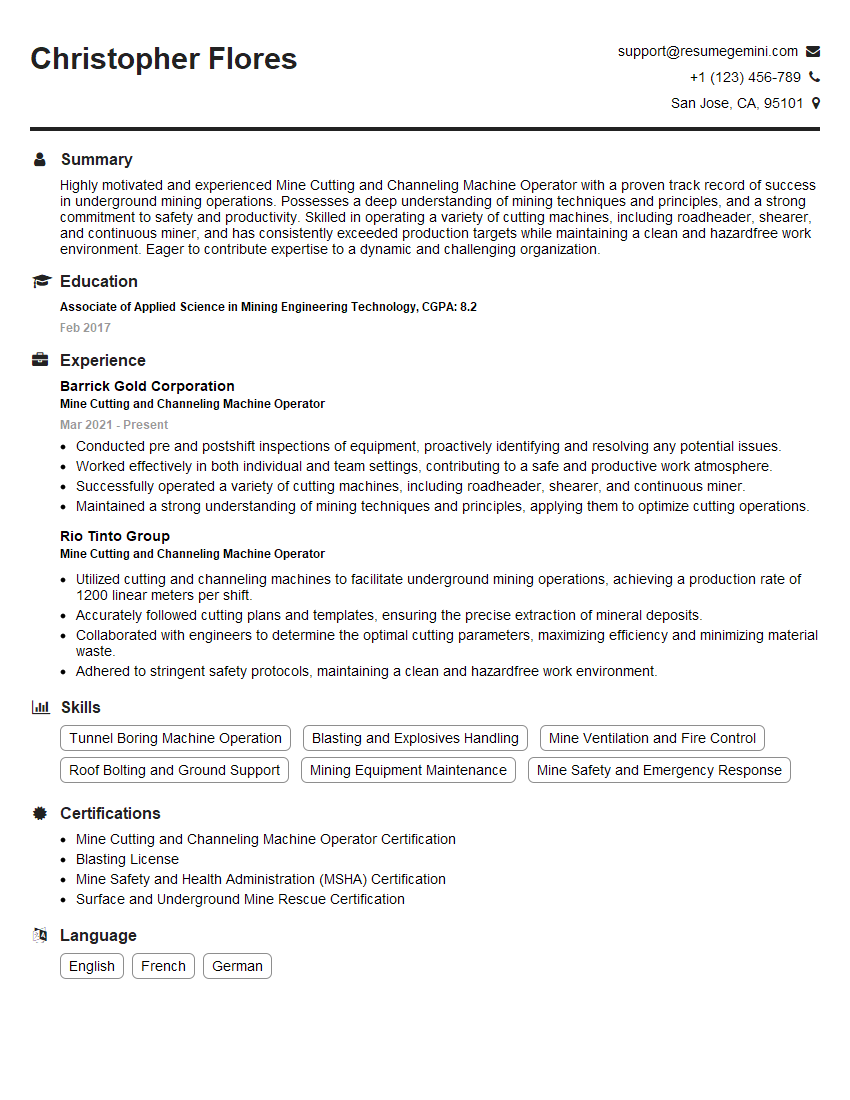

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mine Cutting and Channeling Machine Operator

1. Can you describe the process of operating a mine cutting and channeling machine?

The process of operating a mine cutting and channeling machine involves several steps. Firstly, the machine is positioned at the desired location, and the operator uses a laser level to ensure that it is level. Next, the operator selects the appropriate cutting blade and installs it on the machine. The operator then starts the machine and guides it along the desired cutting path. The machine uses a series of rotating blades to cut a precise channel into the rock or coal.

2. What are the safety precautions that must be followed when operating a mine cutting and channeling machine?

When operating a mine cutting and channeling machine, it is crucial to follow several safety precautions. These precautions include wearing appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, earplugs, and gloves. The operator must also be aware of the surroundings and ensure that there are no obstacles or personnel in the path of the machine. Additionally, the operator must be trained and certified to operate the machine safely.

3. How do you troubleshoot common problems that may arise while operating a mine cutting and channeling machine?

Common problems that may arise while operating a mine cutting and channeling machine include blade wear, hydraulic leaks, and engine problems. To troubleshoot blade wear, the operator can inspect the blades for damage or wear and replace them if necessary. Hydraulic leaks can be identified by checking for fluid leaks and tightening any loose connections. Engine problems can be diagnosed by checking the engine oil level and spark plugs and performing any necessary repairs.

4. What are the different types of cutting and channeling machines used in mining operations?

There are several types of cutting and channeling machines used in mining operations. These include chain saws, wire saws, and roadheaders. Chain saws are used for cutting small channels and slots, while wire saws are used for cutting larger channels and blocks. Roadheaders are heavy-duty machines used for cutting large tunnels and roadways.

5. How do you maintain a mine cutting and channeling machine to ensure optimal performance?

To maintain a mine cutting and channeling machine for optimal performance, regular maintenance is essential. This includes daily inspections to check for any damage or wear and cleaning the machine after each use. Periodically, the machine should be lubricated and serviced by a qualified technician to ensure that all components are functioning correctly.

6. What are the environmental regulations that must be followed when operating a mine cutting and channeling machine?

When operating a mine cutting and channeling machine, it is important to follow environmental regulations to minimize the impact on the environment. These regulations may include controlling dust and noise levels, preventing spills and leaks, and properly disposing of waste materials.

7. How do you calculate the cutting speed and depth of a mine cutting and channeling machine?

To calculate the cutting speed and depth of a mine cutting and channeling machine, several factors must be considered, including the type of rock or coal being cut, the blade size and type, and the machine’s power and torque. The cutting speed is typically measured in meters per minute, while the cutting depth is measured in millimeters.

8. What are the different cutting patterns that can be used with a mine cutting and channeling machine?

Several cutting patterns can be used with a mine cutting and channeling machine, including straight cuts, curved cuts, and angled cuts. The choice of cutting pattern depends on the specific application and the desired results.

9. How do you ensure the accuracy and precision of cuts made with a mine cutting and channeling machine?

To ensure the accuracy and precision of cuts made with a mine cutting and channeling machine, several techniques can be used. These techniques include using a laser level to guide the machine, setting the appropriate cutting depth and speed, and using sharp and properly maintained blades.

10. What are the challenges and hazards associated with operating a mine cutting and channeling machine?

Operating a mine cutting and channeling machine involves several challenges and hazards. These include working in confined spaces, exposure to dust and noise, and the risk of injury from moving parts or falling objects. It is essential to follow safety precautions and receive proper training to minimize these risks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mine Cutting and Channeling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mine Cutting and Channeling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mine Cutting and Channeling Machine Operators are responsible for operating and maintaining cutting and channeling machines, which are used to extract materials from mines. Key responsibilities of this role include:

1. Operating cutting and channeling machines

This involves controlling the machine’s movements and settings to ensure optimal performance and safety.

- Setting up and positioning the machine

- Monitoring the machine’s operation and making adjustments as needed

- Shutting down the machine and performing routine maintenance

2. Maintaining cutting and channeling machines

This includes regular inspections, lubrication, and repairs to ensure the machine is operating safely and efficiently.

- Inspecting the machine for signs of wear or damage

- Lubricating the machine’s moving parts

- Performing minor repairs, such as replacing worn parts

3. Monitoring production

This involves tracking the machine’s output and identifying any potential problems.

- Keeping records of the machine’s production

- Identifying any factors that may affect production

- Reporting any problems to the supervisor

4. Ensuring safety

This involves following safety procedures and wearing appropriate safety gear to minimize the risk of accidents.

- Wearing appropriate safety gear, such as a hard hat and safety glasses

- Following safety procedures, such as lockout/tagout

- Reporting any unsafe conditions or practices

Interview Tips

To ace the interview for a Mine Cutting and Channeling Machine Operator position, candidates should:

1. Research the company and the position

This will show the interviewer that you are interested in the company and the role, and that you have taken the time to learn about the organization and its needs.

- Visit the company’s website to learn about its history, mission, and values.

- Research the specific role you are applying for to understand the key responsibilities and qualifications.

2. Practice your answers to common interview questions

This will help you to feel more confident and prepared during the interview.

- Think about your strengths and weaknesses, and how they relate to the job requirements.

- Prepare examples of your experience that demonstrate your skills and abilities.

3. Be prepared to talk about your safety experience and training

This is an important aspect of the job, and the interviewer will want to know that you are familiar with safety procedures and regulations.

- Describe your experience with lockout/tagout procedures.

- Explain how you would respond to a safety hazard or emergency.

4. Be enthusiastic and positive

The interviewer will be looking for candidates who are passionate about the mining industry and who are excited about the opportunity to work for the company.

- Express your interest in the position and the company.

- Be positive and enthusiastic about your skills and abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mine Cutting and Channeling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!