Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mine Equipment Design Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mine Equipment Design Engineer so you can tailor your answers to impress potential employers.

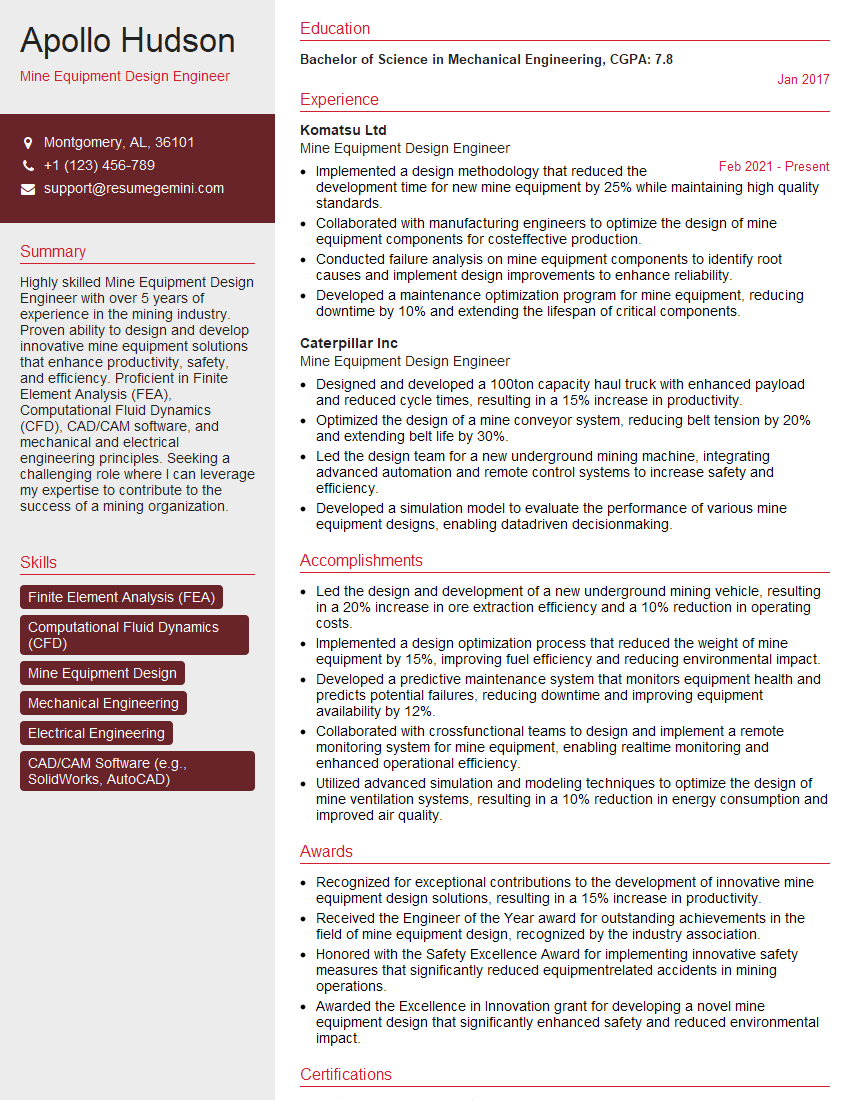

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mine Equipment Design Engineer

1. Explain the process of designing a new piece of mine equipment.

The process of designing a new piece of mine equipment typically involves the following steps:

- Needs assessment: Identify the need for the new equipment, including the specific requirements and constraints.

- Concept generation: Develop and evaluate multiple design concepts that meet the needs assessment.

- Detailed design: Refine the chosen concept into a detailed design, including drawings, specifications, and materials selection.

- Prototyping: Build a prototype to test and validate the design.

- Testing: Conduct rigorous testing to ensure the equipment meets all performance and safety requirements.

- Production: Finalize the design and begin production of the new equipment.

2. What are the key considerations when designing mine equipment for safety?

The key considerations when designing mine equipment for safety include:

- Operator safety: Ensure the equipment is designed to minimize the risk of injury to operators.

- Maintenance safety: Design the equipment for safe and efficient maintenance.

- Electrical safety: Ensure proper electrical design and protection to prevent electrical hazards.

- Mechanical safety: Design the equipment to withstand the harsh mining environment and minimize the risk of mechanical failures.

- Environmental safety: Consider the environmental impact of the equipment and design for sustainability.

3. What are the different types of materials used in mine equipment design, and how do you select the appropriate material for a specific application?

The different types of materials used in mine equipment design include:

- Steel: High strength and durability, used in structural components.

- Aluminum: Lightweight and corrosion-resistant, used in non-structural components.

- Rubber: Shock-absorbing and wear-resistant, used in tires and seals.

- Polymers: Lightweight and durable, used in various components.

- Ceramics: Hard and wear-resistant, used in cutting tools and wear plates.

The selection of the appropriate material depends on the specific application and requirements, considering factors such as strength, durability, weight, cost, and environmental conditions.

4. What software tools do you use in the design and analysis of mine equipment?

Common software tools used in the design and analysis of mine equipment include:

- Computer-aided design (CAD) software: For creating 3D models and drawings.

- Finite element analysis (FEA) software: For stress and deformation analysis.

- Computational fluid dynamics (CFD) software: For fluid flow and heat transfer analysis.

- Simulation software: For simulating equipment behavior and performance.

- Project management software: For project planning and tracking.

5. How do you stay up-to-date with the latest advancements in mine equipment design and technology?

I stay up-to-date with the latest advancements in mine equipment design and technology through the following methods:

- Attending industry conferences and exhibitions.

- Reading technical journals and publications.

- Participating in professional organizations and online forums.

- Networking with other engineers and experts in the field.

- Conducting research and development projects.

6. What are the challenges facing the mining industry in terms of equipment design?

The mining industry is facing several challenges in terms of equipment design, including:

- Increasing demand for productivity and efficiency.

- Need for equipment that can operate in harsh and hazardous environments.

- Environmental regulations and sustainability concerns.

- Safety concerns and the need for autonomous and remote-controlled equipment.

- Shortage of skilled engineers and technicians.

7. What are the ethical considerations involved in mine equipment design?

Ethical considerations involved in mine equipment design include:

- Ensuring the safety and well-being of operators and other personnel.

- Minimizing the environmental impact of the equipment.

- Designing equipment that is sustainable and resource-efficient.

- Considering the social and economic impact of the equipment on local communities.

- Adhering to industry standards and regulations.

8. How do you balance the need for innovation with the need to ensure safety and reliability in mine equipment design?

Balancing the need for innovation with the need to ensure safety and reliability in mine equipment design involves the following strategies:

- Thorough risk assessment and mitigation.

- Use of proven and reliable technologies.

- Rigorous testing and validation.

- Continuous monitoring and improvement of equipment.

- Collaboration with safety professionals and end-users.

9. What is your experience in designing equipment for underground mining operations?

Throughout my career, I have been extensively involved in designing equipment for underground mining operations. My responsibilities included:

- Design and development of continuous miners, shuttle cars, and roof support systems.

- Optimization of equipment for specific geological conditions and mining methods.

- Collaboration with mining engineers and operators to understand their needs and challenges.

- Ensuring compliance with safety regulations and industry standards.

- Troubleshooting and resolving equipment issues during underground operations.

10. How do you approach the design of equipment that must operate in extreme environmental conditions?

Factors to Consider:

- Temperature fluctuations

- Humidity and moisture

- Dust and particulate matter

- Corrosion and erosion

- Extreme pressure and vibration

Design Strategies:

- Use of corrosion-resistant materials and coatings.

- Design for efficient heat dissipation and temperature control.

- Protection against dust and moisture ingress.

- Robust structural design to withstand extreme pressure and vibration.

- Regular maintenance and inspection protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mine Equipment Design Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mine Equipment Design Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mine Equipment Design Engineers play a vital role in the mining industry, where they are responsible for designing, developing, and implementing equipment used in mining operations. Their key responsibilities include:

1. Equipment Design and Development

Design and develop new mining equipment or modify existing equipment to meet specific mining requirements.

- Conduct research and analysis on mining methods, equipment performance, and industry trends.

- Create detailed designs, specifications, and drawings for mining equipment, including components, systems, and assemblies.

2. Equipment Evaluation and Testing

Evaluate and test mining equipment to ensure it meets performance, safety, and regulatory standards.

- Conduct performance tests, simulations, and field trials to assess equipment functionality, durability, and efficiency.

- Analyze test results and recommend design modifications or improvements to optimize equipment performance.

3. Equipment Troubleshooting and Maintenance

Troubleshoot and resolve equipment problems, and develop maintenance plans to ensure optimal equipment performance.

- Diagnose and repair equipment malfunctions, identify root causes, and implement corrective actions.

- Develop and implement preventive maintenance schedules and procedures to minimize equipment downtime and extend equipment life.

4. Collaboration and Communication

Collaborate with other engineers, mining professionals, and stakeholders to ensure effective equipment design and implementation.

- Work closely with mining engineers, geologists, and operators to understand mining requirements and translate them into design specifications.

- Present design proposals, test results, and maintenance recommendations to management and stakeholders.

Interview Tips

To help you ace your interview for a Mine Equipment Design Engineer position, here are some preparation tips and interview hacks:

1. Research the Company and Industry

Familiarize yourself with the mining company you’re applying to, its operations, and the industry trends. This shows the interviewer that you’re genuinely interested in the role and the company.

- Visit the company’s website, review their annual reports, and read industry publications.

2. Practice Your Technical Skills

Review your engineering knowledge, especially in areas related to mining equipment design, materials, and testing. Consider practicing solving common engineering problems or simulating equipment performance.

- Brush up on mechanics, machine design, fluid dynamics, and thermodynamics.

- Review case studies or examples of successful mining equipment designs and innovations.

3. Highlight Your Experience and Projects

Emphasize your relevant experience in equipment design, engineering analysis, and problem-solving. Quantify your accomplishments and provide specific examples of your work.

- Discuss projects where you designed, tested, or troubleshooted mining equipment.

- Mention any patents, publications, or research contributions related to mining equipment.

4. Demonstrate Your Communication and Teamwork Skills

Mining Equipment Design Engineers often collaborate with various stakeholders. Showcase your ability to communicate clearly, present technical information effectively, and work well in a team environment.

- Prepare examples of how you successfully communicated complex technical concepts to non-engineers.

- Discuss instances where you worked effectively within a team to achieve project goals.

5. Prepare Industry-Specific Questions

Ask well-researched questions about the company’s mining operations, equipment maintenance practices, or industry challenges. This demonstrates your enthusiasm, curiosity, and interest in the field.

- Inquire about the company’s plans for equipment upgrades or automation initiatives.

- Ask about any innovative technologies being used in the industry or specific mining challenges the company faces.

Next Step:

Now that you’re armed with the knowledge of Mine Equipment Design Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mine Equipment Design Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini