Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mineral Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

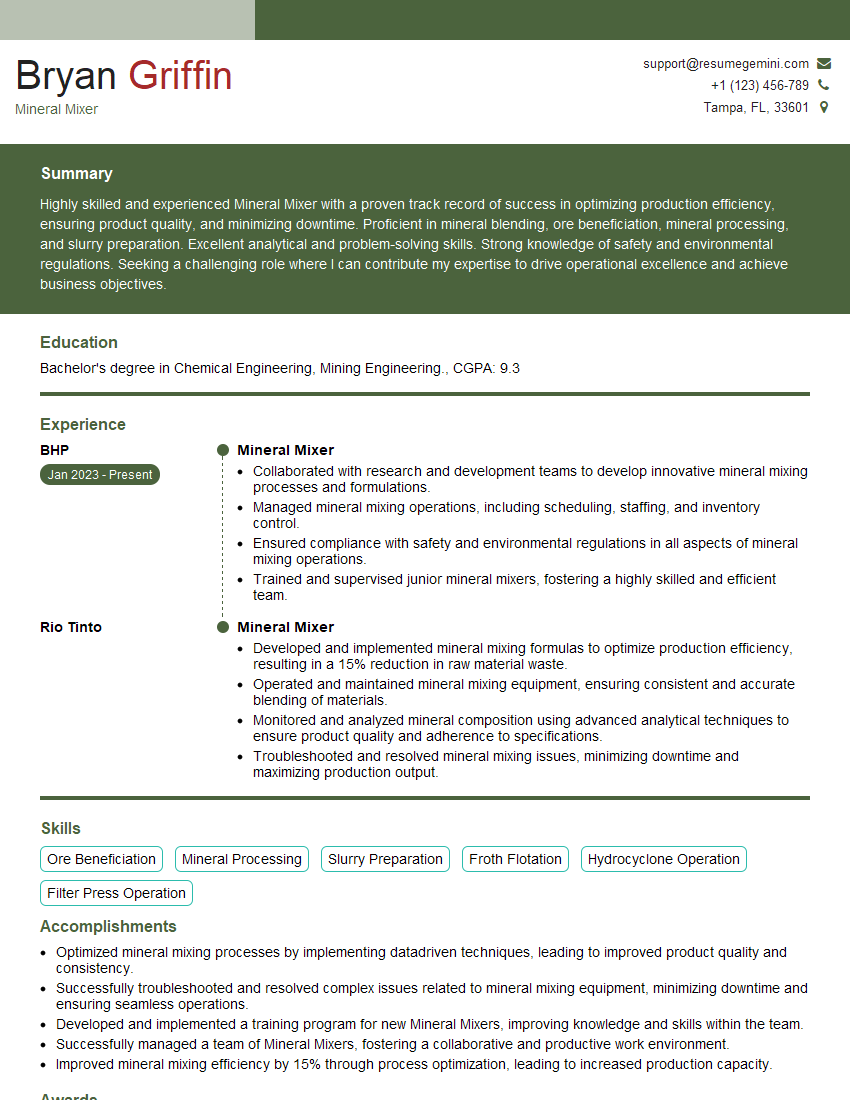

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mineral Mixer

1. Explain the role of a mineral mixer in the mining and mineral processing industry?

The mineral mixer plays a pivotal role in the mining and mineral processing industry, ensuring the optimal blending of various minerals to meet specific customer requirements. They are responsible for:

- Understanding customer specifications and determining the appropriate mineral blend.

- Calculating the ratios and quantities of minerals to be mixed, considering factors such as mineral properties, desired proportions, and market demand.

- Operating and maintaining mineral mixing equipment to ensure accurate and efficient mixing.

- Monitoring the mixing process to ensure that the desired blend is achieved and quality standards are met.

- Documenting the mixing process and maintaining records for quality control and traceability.

- Collaborating with other departments, such as production and quality control, to ensure smooth operations and adherence to quality standards.

2. Describe the different types of mixing methods used in mineral mixing and their applications?

Batch Mixing

- Suitable for small batches and specialty mixtures.

- Involves mixing a specific quantity of minerals in a batch mixer for a predetermined time.

Continuous Mixing

- Ideal for large-scale operations and consistent blends.

- Involves continuously feeding minerals into a mixer while simultaneously discharging the blended product.

Tumbler Mixing

- Used for mixing minerals that require less intense mixing.

- Involves tumbling the minerals in a rotating drum or barrel.

Agitated Mixing

- Suitable for mixing minerals that require higher mixing intensity.

- Involves using impellers or agitators to create turbulence and ensure thorough mixing.

3. Explain the importance of quality control in the mineral mixing process and the techniques used to ensure product consistency?

- Ensures customer satisfaction and compliance with industry standards.

- Prevents contamination and ensures the safety of the final product.

- Optimizes the performance and efficiency of mineral blends.

Techniques for Quality Control:

- Sampling and testing of incoming raw materials.

- Monitoring and controlling the mixing process parameters (e.g., temperature, mixing time).

- Performing regular quality tests on the final blended product (e.g., chemical analysis, particle size distribution).

- Implementing quality management systems (e.g., ISO 9001) to ensure adherence to standards.

- Maintaining detailed records and documentation for traceability and audit purposes.

4. How do you optimize the mineral mixing process to achieve the desired blend properties and minimize waste?

- Understanding the target blend properties and customer specifications.

- Selecting the appropriate mixing method and equipment based on the mineral properties and desired blend.

- Determining the optimal mixing parameters (e.g., mixing time, mixing intensity) through experimentation or modeling.

- Monitoring and adjusting the mixing process in real-time to ensure consistency.

- Minimizing waste by optimizing the blending ratios and reducing spillage or overmixing.

- Implementing automated control systems to ensure accuracy and efficiency.

5. Describe the safety precautions and environmental regulations that must be observed when working in a mineral mixing plant?

Safety Precautions:

- Wearing appropriate personal protective equipment (e.g., gloves, masks, safety glasses).

- Following safe operating procedures for mixing equipment.

- Handling chemicals and hazardous materials with care.

- Maintaining a clean and organized work area.

- Being aware of potential hazards and following emergency protocols.

Environmental Regulations:

- Complying with dust control measures to minimize air pollution.

- Preventing spills and leaks to protect water sources.

- Properly disposing of waste materials and byproducts.

- Maintaining environmental permits and following industry best practices.

6. How do you ensure the accuracy of mineral proportions and ratios in the mixing process?

- Using calibrated weighing equipment and scales.

- Implementing automated weighing and feeding systems.

- Performing regular audits and cross-checking measurements.

- Establishing and adhering to standard operating procedures.

- Training and certifying operators on weighing and measuring techniques.

7. Explain the role of computers and software in modern mineral mixing operations?

- Automating the mixing process and reducing manual labor.

- Controlling and monitoring mixing parameters to ensure accuracy and consistency.

- Managing inventory and tracking mineral usage.

- Generating production reports and quality control documentation.

- Providing real-time data for process optimization and troubleshooting.

8. How do you manage and resolve potential issues that may arise during the mineral mixing process?

- Identifying the root cause of the issue through systematic troubleshooting.

- Implementing corrective actions to resolve the issue and prevent recurrence.

- Communicating effectively with other departments and stakeholders.

- Documenting the issue and resolution for future reference.

- Continuously monitoring the mixing process to identify and address potential issues proactively.

9. Explain the importance of communication and teamwork in the mineral mixing environment?

- Ensures efficient coordination and collaboration among team members.

- Facilitates the exchange of information and knowledge between different departments.

- Promotes a positive and supportive work environment.

- Contributes to improved decision-making and problem-solving.

- Enhances overall productivity and job satisfaction.

10. How do you stay up-to-date with the latest advancements and best practices in mineral mixing?

- Attending industry conferences and workshops.

- Reading technical publications and research papers.

- Networking with other professionals in the field.

- Participating in continuing education programs.

- Seeking certification or accreditation in mineral mixing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mineral Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mineral Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mineral Mixers are responsible for ensuring the accurate and consistent mixing of various minerals and materials used in manufacturing and construction.

1. Material Handling

Receive, handle, and store raw materials, including minerals, aggregates, and additives.

- Operate forklifts or conveyors to move materials.

- Maintain inventory records and monitor stock levels.

2. Mixing Operations

Operate mixing equipment to blend minerals and materials according to specified formulas.

- Monitor mixing processes and adjust parameters as needed to achieve optimal consistency.

- Ensure that mixtures meet quality standards.

3. Quality Control

Conduct quality control tests on mixed materials to verify adherence to specifications.

- Collect samples and perform physical and chemical tests.

- Report deviations from specifications and recommend corrective actions.

4. Maintenance and Troubleshooting

Perform routine maintenance and repairs on mixing equipment.

- Identify and resolve mechanical or electrical issues.

- Lubricate and clean equipment to ensure optimal performance.

Interview Tips

To ace the interview for a Mineral Mixer position, it’s crucial to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company website and read industry publications.

- Attend industry events or webinars.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions related to your skills, experience, and career goals.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your accomplishments and quantify your results.

3. Show Your Passion for Mixing

Emphasize your interest in the mixing process and your desire to contribute to a team that produces high-quality materials.

- Describe previous experiences where you excelled in producing accurate and consistent mixtures.

- Explain how you stay up-to-date on industry best practices in mixing technology.

4. Be Prepared to Talk About Safety

Mineral mixing involves handling hazardous materials. Be ready to discuss your commitment to safety and your understanding of industry regulations.

- Share examples of your safety initiatives in previous roles.

- Highlight your knowledge of material safety data sheets (MSDSs) and proper handling procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mineral Mixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.