Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mirror Fabrication Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mirror Fabrication Supervisor so you can tailor your answers to impress potential employers.

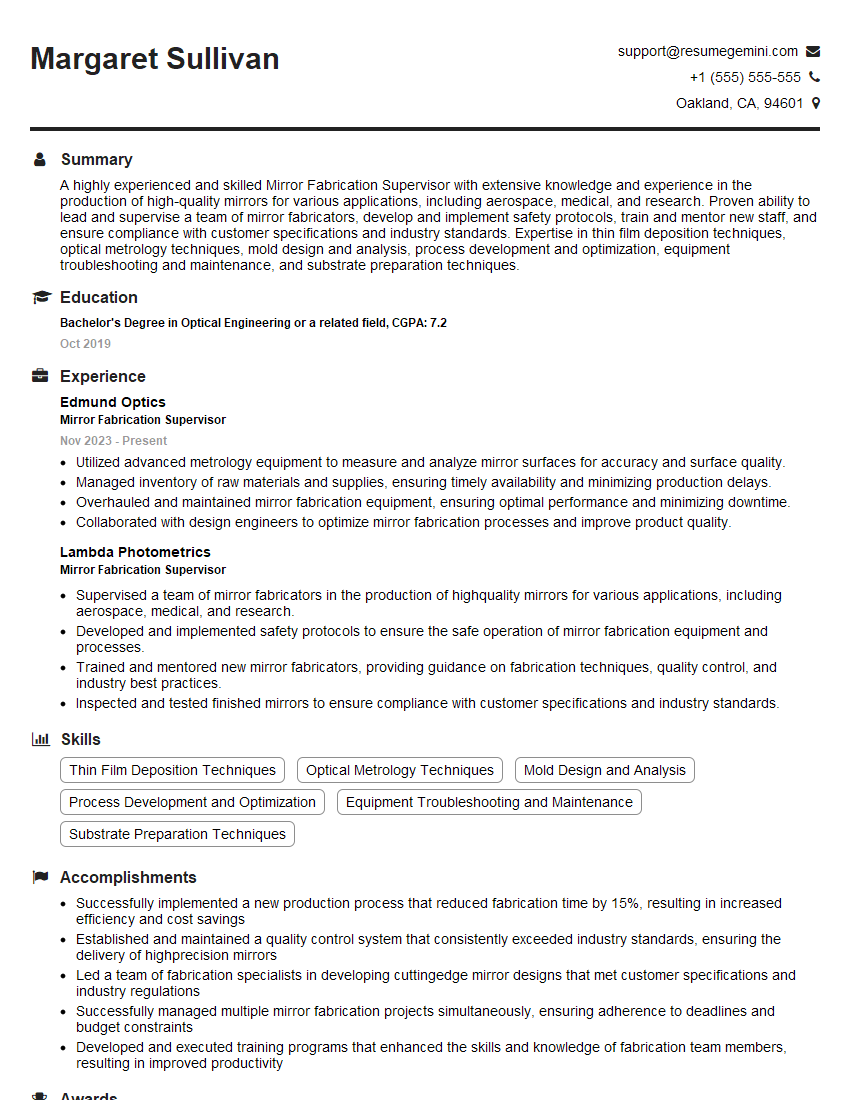

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mirror Fabrication Supervisor

1. How do you ensure the quality of mirrors fabricated in your facility?

- Establishing clear quality standards and specifications for mirrors

- Implementing a rigorous quality control process throughout the fabrication process

- Conducting regular inspections and testing of mirrors at various stages of production

- Utilizing precision measuring instruments and techniques to ensure accuracy and precision

- Maintaining a clean and controlled work environment to minimize contamination

2. What are the key challenges in fabricating large, high-quality mirrors?

Challenges in fabricating large mirrors

- Managing the weight and size of the mirror during handling and processing

- Achieving a high degree of flatness and surface accuracy over a large area

- Minimizing distortion and aberrations caused by gravity and environmental factors

Challenges in fabricating high-quality mirrors

- Controlling surface roughness and defects to minimize scattering and absorption of light

- Ensuring uniform reflectivity and spectral characteristics across the entire surface

- Maintaining the mirror’s performance over time and under various conditions

3. What types of materials are commonly used in mirror fabrication and what are their advantages and disadvantages?

- Glass: Advantages include high optical quality, durability, and versatility. Disadvantages include weight, fragility, and potential for thermal expansion

- Metals: Advantages include strength, rigidity, and low thermal expansion. Disadvantages include high weight and susceptibility to corrosion

- Ceramics: Advantages include high thermal stability, low thermal expansion, and resistance to wear. Disadvantages include brittleness and difficulty in machining

- Polymers: Advantages include lightweight, flexibility, and ease of processing. Disadvantages include relatively low optical quality and durability

4. What are the different techniques used to polish and finish mirrors and how do they affect the mirror’s properties?

- Mechanical polishing: Uses abrasive materials to remove material and achieve the desired surface finish. Can produce high-quality surfaces but is time-consuming

- Chemical polishing: Uses chemical reactions to remove material and smooth the surface. Can produce a high degree of surface accuracy and finish

- Laser polishing: Uses a laser to remove material and polish the surface. Can produce extremely smooth and precise surfaces

- Ion beam figuring: Uses a beam of ions to sputter away material and shape the surface. Can produce high-precision and complex shapes

5. How do you manage the environmental factors that can affect mirror performance, such as temperature, humidity, and vibration?

- Temperature control: Maintaining a stable temperature environment to minimize thermal expansion and distortion

- Humidity control: Controlling humidity levels to prevent moisture condensation and corrosion

- Vibration isolation: Using vibration isolation systems to minimize the effects of external vibrations on the mirror

- Protective coatings: Applying protective coatings to the mirror surface to enhance durability and resistance to environmental factors

6. What are the latest advancements in mirror fabrication technology and how are they impacting the industry?

- Additive manufacturing: Using 3D printing techniques to create complex and customized mirrors

- Ultra-precision diamond turning: Using advanced diamond turning machines to achieve extremely high surface accuracy and finish

- Advanced metrology techniques: Using non-contact and high-resolution metrology tools to measure and characterize mirror surfaces

- Automated inspection systems: Using automated systems to inspect and detect defects in mirrors

7. How do you ensure that your fabrication processes meet the specific requirements of different applications, such as medical, aerospace, or research?

- Understanding application requirements: Thoroughly understanding the specific requirements and specifications of each application

- Tailoring fabrication processes: Adapting fabrication processes to meet the specific requirements, such as using specialized materials or techniques

- Customized testing and inspection: Developing customized testing and inspection procedures to ensure compliance with application requirements

- Collaboration with customers: Maintaining close collaboration with customers to obtain feedback and ensure satisfaction

8. How do you manage a team of mirror fabricators and ensure their productivity and efficiency?

- Clear communication: Establishing clear expectations, roles, and responsibilities for team members

- Skill development: Providing training and opportunities for team members to enhance their skills and knowledge

- Empowerment: Giving team members the authority and autonomy to make decisions and solve problems

- Performance monitoring: Tracking team performance, identifying areas for improvement, and providing feedback

9. How do you stay up-to-date with the latest advancements and best practices in mirror fabrication?

- Industry conferences and workshops: Attending industry events to learn about new technologies and techniques

- Technical journals and publications: Reading technical journals and publications to stay informed about research and developments

- Online resources and webinars: Utilizing online resources and webinars to access the latest information

- Collaboration with experts: Networking with experts in the field to exchange knowledge and ideas

10. What are your thoughts on the future of mirror fabrication and how do you see the industry evolving?

- Increased automation and robotics: Adoption of advanced automation and robotics for improved efficiency and precision

- Next-generation materials: Development and use of new and improved materials with enhanced optical properties

- Customized and specialized mirrors: Growing demand for customized and specialized mirrors for specific applications

- Sustainability: Increasing focus on sustainable practices in mirror fabrication to reduce environmental impact

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mirror Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mirror Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supervising Production and Quality

The Mirror Fabrication Supervisor is responsible for overseeing all aspects of mirror fabrication, ensuring that mirrors meet the required specifications and quality standards.

- Monitoring production processes and ensuring adherence to established procedures

- Inspecting mirrors at various stages of fabrication to identify and correct any defects

- Maintaining quality control records and reporting any deviations from standards

- Working with engineers to develop and implement new fabrication techniques to improve efficiency and quality

Managing a Team

The supervisor is responsible for leading and motivating a team of mirror fabricators.

- Assigning tasks, providing guidance, and evaluating performance

- Ensuring that employees have the necessary training and resources to perform their jobs effectively

- Maintaining a positive and productive work environment

- Collaborating with other departments to ensure smooth production flow

Health and Safety

The supervisor is responsible for maintaining a safe and healthy work environment.

- Enforcing safety regulations and ensuring that employees follow proper procedures

- Conducting safety training and drills

- Managing hazardous waste disposal and ensuring compliance with environmental regulations

Administrative Duties

The supervisor is responsible for various administrative tasks.

- Preparing and maintaining production schedules

- Managing inventory and ordering materials

- Preparing reports and presentations on production and quality

Interview Tips

Research the Company and Position

Before the interview, thoroughly research the company and the specific role you are applying for. This will help you to understand the company’s culture and demonstrate that you have a genuine interest in the position.

- Visit the company’s website and social media pages

- Read industry publications and news articles about the company

- Network with people who work or have worked at the company

Practice Your Answers

Take the time to prepare for common interview questions, especially those related to your experience and qualifications for the role. Practice answering these questions out loud to improve your delivery and confidence.

- Review your resume and be prepared to discuss your experience and skills

- Think about examples of times when you have successfully led a team or solved a problem

- Prepare questions to ask the interviewer about the company and the position

Professionalism and Appearance

Dress appropriately for the interview and arrive on time. Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Wear a clean, pressed suit or business casual attire

- Be well-groomed and make sure your hair and nails are neat

- Bring a portfolio or samples of your work if appropriate

Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. This is a chance to reiterate your interest in the position and highlight any key points from the interview.

- Keep your note brief and to the point

- Thank the interviewer for their time and express your appreciation for the opportunity to interview

- Reiterate your interest in the position and how your skills and experience align with the company’s needs

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mirror Fabrication Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.