Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mirror Finishing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

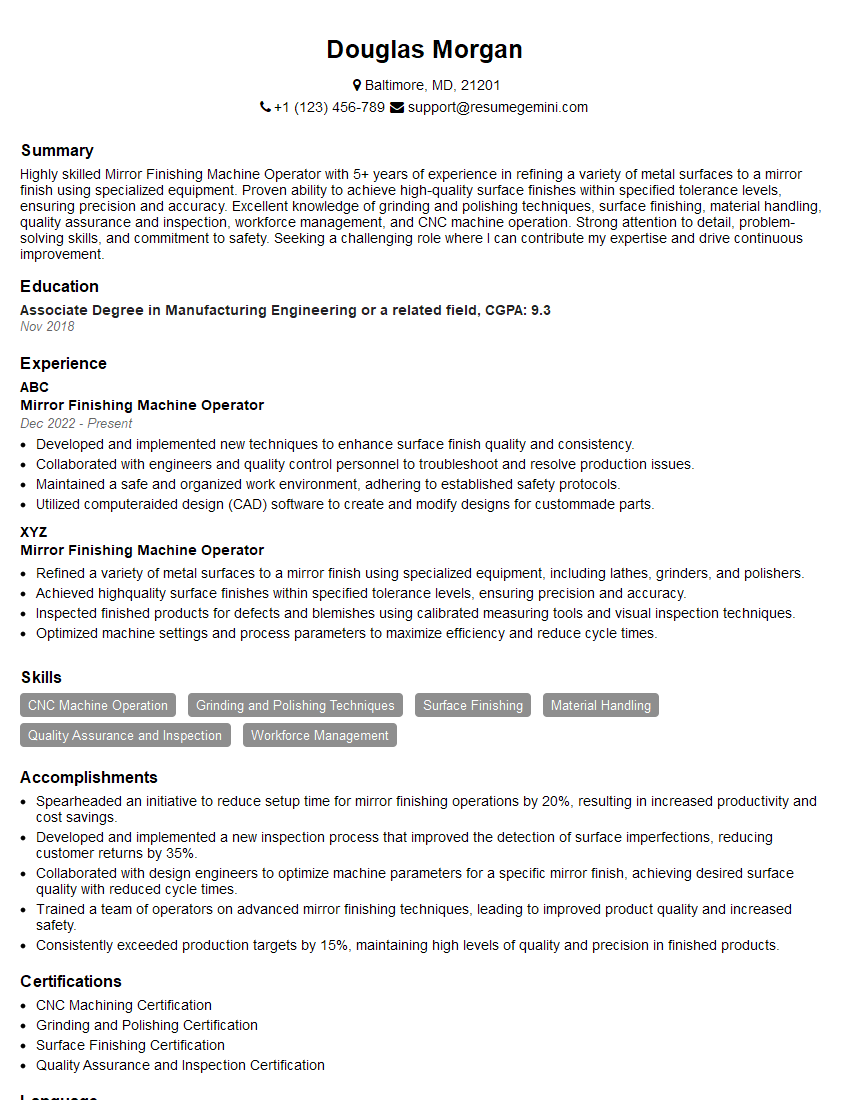

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mirror Finishing Machine Operator

1. Describe the primary procedures involved in mirror finishing operations?

The mirror finishing process involves several key steps to achieve a high-quality finish:

- Pre-polishing: Preparing the surface by removing burrs and imperfections using abrasive belts or pads.

- Buffing: Employing rotating buffing wheels with abrasive compounds to smooth and refine the surface further.

- Polishing: Using specialized polishing wheels with finer abrasives to create a smooth, reflective finish.

- Inspection: Thoroughly examining the finished product to ensure it meets specifications and desired quality standards.

2. What are the different types of abrasives used in mirror finishing, and how do they differ in their applications?

Types of Abrasives

- Aluminum Oxide: Common abrasive used in pre-polishing due to its fast-cutting properties.

- Silicon Carbide: Ideal for buffing operations as it produces a finer finish.

- Cerium Oxide: Specialized abrasive used in final polishing to achieve a high-gloss finish.

Applications

- Pre-polishing: Coarse abrasives like aluminum oxide are preferred for initial surface preparation.

- Buffing: Silicon carbide’s medium grit size helps smooth and refine the surface.

- Polishing: Fine abrasives like cerium oxide provide the necessary smoothness and reflectivity.

3. Explain the role of lubricants in mirror finishing and discuss their effects on the process?

Lubricants play a crucial role in mirror finishing:

- Cooling: Lubricants prevent excessive heat build-up, which can damage the workpiece and abrasive materials.

- Deburring: Lubricants aid in removing burrs and chips, ensuring a smoother surface finish.

- Uniformity: Lubricants create a consistent film between the abrasive and workpiece, promoting even polishing.

- Extended Abrasive Life: Lubricants help reduce friction, extending the lifespan of abrasive wheels and pads.

4. How do you ensure the dimensional accuracy of the workpiece during mirror finishing?

Maintaining dimensional accuracy is crucial in mirror finishing:

- Precise Setup: Proper alignment of the workpiece and machine is essential to avoid excessive material removal.

- Gradual Abrasive Selection: Starting with coarse abrasives and gradually moving to finer ones ensures controlled material removal.

- Regular Measurements: Frequent measurements using precision instruments help monitor progress and prevent over-polishing.

- Operator Skill: Experienced operators possess the expertise to maintain consistent pressure and avoid uneven finishing.

5. Discuss the importance of surface preparation prior to mirror finishing?

Proper surface preparation sets the stage for successful mirror finishing:

- Initial Cleaning: Removing dirt, grease, or oxides ensures proper bonding of abrasives to the workpiece.

- Grinding or Sanding: Creating a smooth initial surface reduces the amount of material that needs to be removed during mirror finishing.

- Pre-polishing: Pre-polishing helps remove surface imperfections and prepares the surface for finer abrasives.

- Eliminates Defects: Proper preparation minimizes the likelihood of defects or inconsistencies in the final mirrored finish.

6. How do you troubleshoot common issues encountered in mirror finishing operations?

Troubleshooting is essential for efficient mirror finishing:

- Uneven Finish: May indicate uneven pressure, improper abrasive selection, or workpiece misalignment.

- Surface Burning: Overheating can cause workpiece discoloration; adjust polishing speed, pressure, or lubrication.

- Poor Reflectivity: Ensure proper surface preparation, use finer abrasives, and adjust polishing parameters.

- Chatter Marks: Caused by workpiece vibrations; check machine stability, use anti-vibration pads, or adjust clamping.

7. What safety precautions are necessary when operating a mirror finishing machine?

Safety is paramount in mirror finishing:

- Eye Protection: Wear safety goggles to protect from flying debris and abrasives.

- Respiratory Protection: Use a respirator to avoid inhaling dust and fumes.

- Proper Attire: Wear tight-fitting clothing, gloves, and closed-toe shoes to prevent entanglement or injury.

- Machine Guarding: Ensure all machine guards are in place and functioning properly.

8. How do you maintain and calibrate a mirror finishing machine to ensure optimal performance?

Maintenance and calibration are crucial for machine efficiency:

- Regular Cleaning: Keep the machine clean to prevent abrasive buildup and ensure proper operation.

- Lubrication: Lubricate moving parts regularly to minimize friction and wear.

- Calibration: Calibrate the machine according to manufacturer’s specifications to ensure precision and accuracy.

- Belt/Pad Inspection: Regularly inspect and replace worn or damaged belts or pads to maintain desired finishing quality.

9. How do you stay updated on the latest techniques and advancements in mirror finishing?

Continuous learning is essential in mirror finishing:

- Industry Publications: Read trade magazines and journals to stay abreast of new technologies and best practices.

- Manufacturer Training: Attend training sessions offered by equipment manufacturers to learn about advancements.

- Conferences and Exhibitions: Network with professionals and learn about the latest innovations at industry events.

- Online Resources: Utilize online forums and technical blogs to connect with other mirror finishers and share knowledge.

10. What makes you a suitable candidate for this Mirror Finishing Machine Operator position?

Highlight your skills, experience, and knowledge:

- Technical Expertise: Demonstrate a strong understanding of mirror finishing principles, machine operation, and troubleshooting.

- Precision and Attention to Detail: Emphasize your commitment to achieving high-quality finishes and maintaining dimensional accuracy.

- Safety Consciousness: Highlight your adherence to safety protocols and ability to operate equipment safely.

- Problem-Solving Abilities: Showcase your ability to diagnose and resolve issues promptly to minimize downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mirror Finishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mirror Finishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mirror Finishing Machine Operators play a crucial role in the production process, ensuring the smooth operation of machines and the delivery of high-quality finished products.

1. Machine Operation and Maintenance

Mastering the operation of mirror finishing machines, including setting up, operating, and troubleshooting them.

- Performing regular maintenance tasks to ensure optimal machine performance, such as lubrication, cleaning, and adjustments.

- Monitoring machine performance and identifying any issues or potential problems.

2. Material Handling and Finishing

Handling and loading various materials into the machine for finishing, ensuring proper placement and orientation.

- Selecting appropriate abrasives and polishing compounds based on the material and desired finish.

- Adjusting machine settings, such as speed, pressure, and abrasive type, to achieve the required surface finish.

3. Quality Control and Inspection

Conducting thorough inspections of finished products to ensure they meet the required specifications and quality standards.

- Using measuring tools and gauges to verify dimensions, surface roughness, and other quality parameters.

- Identifying and addressing any defects or non-conformance issues with the finished products.

4. Safety and Compliance

Adhering to all safety regulations and operating procedures to maintain a safe and compliant work environment.

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection.

- Following established lockout/tagout procedures when performing maintenance or repairs.

Interview Tips

Preparing for a Mirror Finishing Machine Operator interview requires a combination of technical knowledge, attention to detail, and a commitment to safety.

1. Highlight Your Technical Expertise

Emphasize your proficiency in operating mirror finishing machines, including your understanding of machine components, settings, and troubleshooting techniques. Provide specific examples of your experience and the results you achieved.

- Sample Question: Describe a time when you successfully diagnosed and resolved a technical issue with a mirror finishing machine.

2. Demonstrate Your Quality Focus

Showcase your commitment to delivering high-quality finished products by highlighting your attention to detail and meticulous inspection techniques. Discuss your knowledge of quality control standards and your ability to identify and address any non-conformances.

- Sample Question: How do you ensure that the finished products meet the required specifications and quality standards?

3. Emphasize Your Safety Consciousness

Emphasize your understanding of and adherence to safety regulations and operating procedures. Highlight your experience in maintaining a safe work environment and your commitment to following established lockout/tagout protocols.

- Sample Question: Describe your knowledge and experience with safety protocols in a manufacturing environment.

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview demonstrates your interest and engagement. Prepare questions related to the company’s commitment to quality, safety, and employee development.

- Sample Question: What are the company’s goals for improving product quality in the next year?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mirror Finishing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mirror Finishing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.