Feeling lost in a sea of interview questions? Landed that dream interview for Missile Pad Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Missile Pad Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

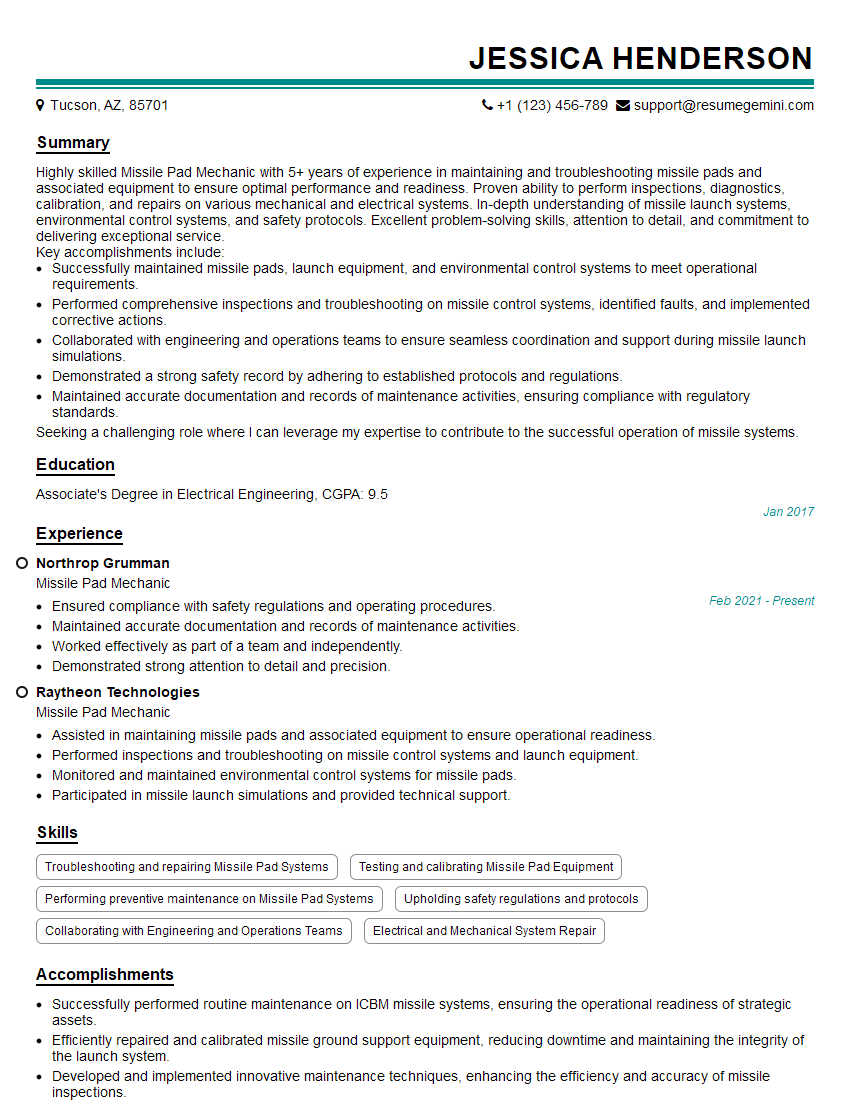

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Missile Pad Mechanic

1. Explain the process of performing preventive maintenance on a missile pad?

Preventive maintenance on a missile pad involves regular inspections and servicing to ensure the system is operating at peak performance and to prevent failures.

- Visual inspection: Inspecting the pad for any visible signs of damage or wear, such as cracks, corrosion, loose connections, or leaks.

- Mechanical inspection: Checking the mechanical components of the pad, such as the launch platform, guidance system, and propellant loading systems, for proper operation.

- Electrical inspection: Verifying that all electrical systems, including wiring, connectors, and power supplies, are functioning correctly.

- Hydraulic inspection: Ensuring that hydraulic systems, including pumps, valves, and actuators, are operating within specified parameters.

- Lubrication: Applying lubricants to moving parts to reduce friction and prevent wear.

- Calibration: Adjusting and calibrating sensors, instruments, and control systems to ensure accuracy and reliability.

- Documentation: Recording all maintenance activities, inspections, and repairs performed on the missile pad.

2. Describe the steps involved in troubleshooting and repairing a missile pad malfunction?

Identifying the issue

- Conducting a thorough inspection of the missile pad to identify the source of the malfunction.

- Analyzing system logs, error messages, and diagnostic data to pinpoint the affected component or subsystem.

- Consulting technical manuals and documentation to understand the expected behavior and potential causes of failure.

Troubleshooting and repairs

- Replacing or repairing faulty components, such as sensors, actuators, or electrical connections.

- Adjusting system parameters and settings to restore proper operation.

- Performing software updates or patches to address software-related issues.

- Conducting functional testing to verify that the repairs have resolved the malfunction.

3. What are the safety protocols that must be followed when working on a missile pad?

- Authorization: Obtaining proper authorization and clearance before entering restricted areas or performing any maintenance activities.

- Personal protective equipment: Wearing appropriate personal protective equipment, such as safety glasses, gloves, and coveralls, to protect against potential hazards.

- Electrical safety: Ensuring that all electrical systems are de-energized and grounded before touching or working on them.

- Explosive safety: Handling explosives and propellants with extreme caution, following established procedures and using proper tools and equipment.

- Confined space entry: Observing proper safety protocols when working in confined spaces, such as missile silos or bunkers, including ventilation, lighting, and communication.

- Emergency response: Being familiar with emergency response procedures and evacuation plans in case of accidents or malfunctions.

- Continuous training: Participating in regular safety training and refresher courses to stay up-to-date on best practices and safety regulations.

4. How do you ensure that missile pad systems are calibrated and meet operational requirements?

- Calibration schedule: Following a regular calibration schedule based on manufacturer recommendations and operational requirements.

- Calibration equipment: Using certified and traceable calibration equipment to ensure accuracy.

- Calibration procedures: Adhering to established calibration procedures and following manufacturer’s guidelines.

- Documentation: Maintaining detailed records of all calibration activities, including the date, time, equipment used, and calibration results.

- Verification: Performing functional testing or system simulations to verify that the calibrated systems are meeting operational requirements.

5. Explain the role of hydraulic systems in missile pad operations?

- Launch platform movement: Powering the hydraulic actuators that control the movement of the launch platform.

- Guidance system: Operating the hydraulic systems that position and align the missile during launch.

- Propellant loading: Controlling the hydraulic valves and pumps that fill the missile’s propellant tanks.

- Safety systems: Activating hydraulic safety mechanisms, such as hold-down clamps and thrust vector control systems.

- Maintenance: Facilitating maintenance and repair activities by providing hydraulic power for lifting equipment and tools.

6. Describe the importance of electrical systems in missile pad operations?

- Power distribution: Supplying electricity to all components and subsystems of the missile pad, including computers, sensors, and actuators.

- Control and communication: Enabling communication between the launch control center and the missile pad systems.

- Guidance and navigation: Providing electrical power to the guidance and navigation systems that control the missile’s trajectory.

- Safety systems: Activating electrical safety mechanisms, such as interlocks and emergency shutdown systems.

- Diagnostics: Facilitating diagnostics and troubleshooting by providing data and feedback from sensors and monitoring systems.

7. Explain the significance of mechanical systems in missile pad operations?

- Launch platform: Providing a stable and secure base for the missile during launch.

- Guidance system: Positioning and aligning the missile accurately using mechanical actuators.

- Propellant loading systems: Filling the missile’s propellant tanks safely and efficiently.

- Safety systems: Employing mechanical safety devices, such as hold-down clamps and thrust vector control systems, to prevent accidents.

- Maintenance: Facilitating maintenance and repairs by allowing access to components and providing mechanical support.

8. Describe the types of documentation required for missile pad maintenance and operations?

- Technical manuals: Providing detailed instructions for operating, maintaining, and troubleshooting the missile pad systems.

- Maintenance logs: Recording all maintenance activities, inspections, and repairs performed on the missile pad.

- Calibration records: Documenting the calibration history and status of all critical systems and equipment.

- Inspection reports: Summarizing the findings and recommendations from regular inspections and safety audits.

- Operational procedures: Describing the step-by-step procedures for preparing, launching, and securing the missile pad.

9. What is your experience in working with missile guidance systems?

In my previous role as a Missile Guidance Systems Technician, I was responsible for maintaining, calibrating, and troubleshooting the missile guidance systems used in our organization’s missile defense program.

- Maintenance and repairs: I performed routine maintenance and repairs on guidance system components, including inertial navigation units, radar seekers, and control actuators.

- Calibration: I calibrated the guidance systems using specialized equipment and procedures to ensure accurate and reliable performance.

- Troubleshooting: I diagnosed and resolved malfunctions in the guidance systems, utilizing diagnostic tools and troubleshooting techniques.

- Testing: I conducted functional testing and simulations to verify the performance and accuracy of the guidance systems before deployment.

10. How do you stay up-to-date on the latest advancements in missile pad technology?

- Technical conferences: Attending industry conferences and workshops to learn about new technologies and best practices.

- Training courses: Participating in training courses offered by manufacturers and industry experts to enhance my knowledge and skills.

- Technical journals: Reading scientific and technical journals to stay informed about the latest developments in missile pad design and operations.

- Online resources: Utilizing online resources, forums, and discussion groups to connect with other professionals and access up-to-date information.

- Collaboration: Engaging in discussions and sharing knowledge with colleagues and industry partners to stay abreast of emerging trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Missile Pad Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Missile Pad Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Missile Pad Mechanic, you will:

1. Maintain and Repair Missile Launch Systems

Inspect, troubleshoot, and perform repairs on missile launch systems to ensure their optimal functionality. This includes systems such as guidance controls, hydraulics, electrical systems, and propulsion subsystems.

2. Perform Scheduled and Unscheduled Maintenance

Adhere to preventive maintenance schedules to inspect, clean, lubricate, and adjust missile launch systems. Respond promptly to unscheduled maintenance requests to address malfunctions or anomalies.

3. Handle and Store Ammunition

Safely handle, transport, and store munitions in designated areas according to established protocols. Ensure proper inventory and documentation of all ammunition.

4. Support Missile Launch Operations

Provide technical support during missile launch operations. Monitor systems, prepare equipment, and assist in the launch process as required.

Interview Tips

1. Research the Company and Position

- Visit the company website and read any relevant news articles or industry publications to gain an understanding of their mission, values, and current projects.

- Review the job description carefully and identify the specific skills, qualifications, and experience required for the role.

2. Tailor Your Resume and Cover Letter

- Highlight relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your capabilities.

- Craft a cover letter that expresses your enthusiasm for the position and explains how your qualifications make you a suitable candidate.

3. Practice Answering Common Interview Questions

- Prepare for questions related to your technical expertise, problem-solving abilities, and experience in missile maintenance. Practice answering questions about safety protocols and your commitment to teamwork.

- Consider potential behavioral questions and prepare specific examples that showcase your skills and work ethic.

4. Be Enthusiastic and Confident

- Demonstrate your passion for the role and your eagerness to contribute to the team. Show confidence in your abilities and your willingness to learn and grow.

- Maintain eye contact, ask thoughtful questions, and express your appreciation for the opportunity to interview.

5. Follow Up

- After the interview, send a thank-you note to the interviewer, reiterating your interest in the position and expressing gratitude for their time.

- If you do not hear back within the timeframe provided, consider following up by email or phone to inquire about the status of your application.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Missile Pad Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Missile Pad Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.