Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Miter Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

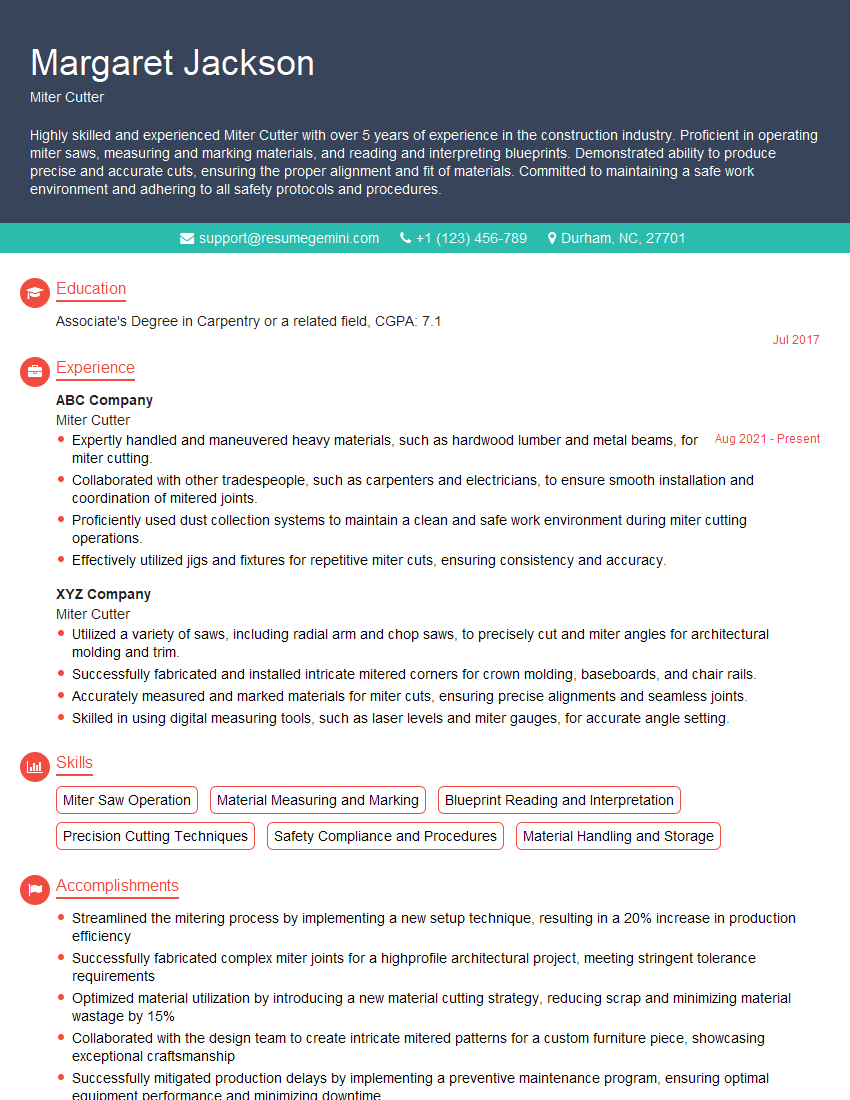

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Miter Cutter

1. Explain the process of miter cutting?

Miter cutting is a woodworking technique that involves cutting two pieces of material at an angle so that they can be joined together to form a corner. The most common type of miter cut is a 45-degree cut, but other angles can also be used. Here is a step-by-step overview of the process of miter cutting:

- Measure and mark the cut lines: Use a measuring tape and a pencil to measure and mark the cut lines on the two pieces of material. The cut lines should be perpendicular to the edges of the material.

- Set up the miter saw: Set the miter saw to the desired angle. The most common miter angle is 45 degrees, but other angles can also be used.

- Position the material on the saw: Place the first piece of material on the miter saw table and align the cut line with the saw blade. Clamp the material in place.

- Make the cut: Slowly lower the saw blade onto the material and make the cut. Be sure to keep the material firmly clamped in place. Repeat the process for the second piece of material.

- Dry fit the pieces together: Dry fit the two pieces of material together to ensure that they fit properly. Make any necessary adjustments to the cut angles before gluing and assembling the pieces.

2. What are the different types of miter saws?

- Single-bevel miter saws: Single-bevel miter saws are the most basic type of miter saw. They can only make cuts at a single angle, which is usually 45 degrees. Single-bevel miter saws are relatively inexpensive and easy to use.

- Dual-bevel miter saws: Dual-bevel miter saws can make cuts at both left and right angles. This makes them more versatile than single-bevel miter saws, but they are also more expensive.

- Compound miter saws: Compound miter saws can make both miter cuts and bevel cuts. This makes them the most versatile type of miter saw, but they are also the most expensive.

3. What are the safety precautions that need to be taken when using a miter saw?

- Wear safety glasses: Always wear safety glasses when using a miter saw. This will protect your eyes from flying wood chips and sawdust.

- Use a push stick: Always use a push stick to push the material through the saw blade. This will help to prevent your hands from coming into contact with the blade.

- Keep your hands clear of the blade: Never reach over or around the saw blade. Keep your hands well clear of the blade at all times.

- Unplug the saw when not in use: Always unplug the saw when it is not in use. This will help to prevent accidental starts.

4. What are the common problems that can occur when using a miter saw?

- The blade is not sharp: A dull blade will produce ragged cuts and can cause the saw to bog down. Be sure to keep your saw blade sharp.

- The material is not clamped securely: If the material is not clamped securely, it can move during the cut and cause the blade to bind. Be sure to clamp the material securely before making the cut.

- The saw is not properly aligned: If the saw is not properly aligned, the blade will not cut at the correct angle. Be sure to check the saw’s alignment before making any cuts.

5. What are some tips for getting the most out of a miter saw?

- Use a sharp blade: A sharp blade will produce clean, accurate cuts. Be sure to keep your saw blade sharp.

- Use a push stick: A push stick will help to keep your hands out of the way of the blade. This will help to prevent accidents.

- Clamp the material securely: Clamping the material securely will help to prevent it from moving during the cut. This will help to produce accurate cuts.

- Check the saw’s alignment: Checking the saw’s alignment will help to ensure that the blade is cutting at the correct angle. This will help to produce accurate cuts.

6. What is the difference between a miter cut and a bevel cut?

- Miter cut: A miter cut is a cut that is made at an angle across the grain of the wood. Miter cuts are often used to create corners in picture frames, molding, and other woodworking projects.

- Bevel cut: A bevel cut is a cut that is made at an angle to the face of the wood. Bevel cuts are often used to create chamfers, rabbets, and other woodworking joints.

7. What is a compound miter cut?

- A compound miter cut is a cut that is made at an angle both across the grain of the wood and to the face of the wood. Compound miter cuts are often used to create complex woodworking joints, such as those found in bay windows and crown molding.

8. What are the different types of miter joints?

- Butt joint: A butt joint is the simplest type of miter joint. It is created by simply butting two pieces of wood together at a 90-degree angle.

- Lap joint: A lap joint is a stronger type of miter joint. It is created by overlapping two pieces of wood and then cutting a 45-degree angle on each piece. The two pieces are then glued and clamped together.

- Dado joint: A dado joint is a type of miter joint that is used to create a shelf or other type of support. It is created by cutting a groove in one piece of wood and then cutting a matching groove in the other piece. The two pieces are then glued and clamped together.

9. What are the different types of miter clamps?

- Bar clamps: Bar clamps are the most common type of miter clamp. They are made of two parallel bars that are connected by a screw. Bar clamps can be used to clamp miter joints of all sizes.

- Corner clamps: Corner clamps are designed specifically for clamping miter joints. They have a 90-degree angle that helps to align the two pieces of wood. Corner clamps can be used to clamp miter joints of all sizes, but they are especially useful for small miter joints.

- Band clamps: Band clamps are made of a flexible band that is tightened around the miter joint. Band clamps are ideal for clamping miter joints that are large or odd-shaped.

10. What are the different types of miter saws?

- Radial arm saw: A radial arm saw is a type of miter saw that has a blade that moves on a radial arm. This allows the saw to make cuts at a variety of angles, including miter cuts, bevel cuts, and compound miter cuts.

- Compound miter saw: A compound miter saw is a type of miter saw that has a blade that can tilt both left and right. This allows the saw to make compound miter cuts, which are cuts that are made at an angle both across the grain of the wood and to the face of the wood.

- Sliding compound miter saw: A sliding compound miter saw is a type of miter saw that has a blade that can slide back and forth on a track. This allows the saw to make wider cuts than a standard compound miter saw.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Miter Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Miter Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Miter Cutter is responsible for cutting and shaping materials to create precise angles for various projects. The key job responsibilities include:

1. Material Preparation and Cutting

Measuring, marking, and cutting materials such as wood, metal, or plastic to specified dimensions and angles using a miter saw or other cutting equipment.

2. Angle Measurement and Precision

Using protractors, bevels, and other measuring tools to ensure accurate angle measurements and precise cuts.

3. Operation and Maintenance of Machinery

Setting up, operating, and maintaining miter saws and other cutting machinery, including blade changes and adjustments.

4. Safety and Compliance

Following safety regulations, wearing appropriate protective gear, and maintaining a clean and organized work area.

5. Quality Control and Inspection

Inspecting finished cuts to ensure they meet specifications and making adjustments as needed to maintain quality standards.

6. Material Handling and Storage

Handling and storing materials safely and efficiently to minimize waste and damage.

7. Teamwork and Communication

Collaborating with other team members, providing assistance, and communicating project requirements and updates.

Interview Tips

To ace the interview for a Miter Cutter position, candidates should consider the following tips:

1. Research the Company and Job Description

Before the interview, thoroughly research the company’s background, industry, and values. Familiarize yourself with the job description to understand the specific responsibilities and requirements of the role.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in operating miter saws or other cutting equipment. Showcase your proficiency in measuring angles, understanding construction principles, and ensuring precision. Highlight any additional skills, such as woodworking, metalworking, or project management.

3. Demonstrate Attention to Detail and Problem-Solving Abilities

Miter cutting requires precision and attention to detail. During the interview, provide examples of your past work that demonstrate your meticulous nature and ability to solve problems efficiently.

4. Prepare for Technical Questions

Be prepared to answer questions related to the operation and maintenance of miter saws, blade selection, and safety precautions. Consider bringing a portfolio or examples of your work to demonstrate your practical knowledge.

5. Showcase Safety Awareness

Stress your commitment to workplace safety. Discuss your knowledge of industry regulations and your practices for handling and storing materials safely. Highlight any safety certifications or training you have completed.

6. Ask Informed Questions

Towards the end of the interview, prepare thoughtful questions to show your interest and engagement. Ask about the company’s safety protocols, industry trends, or opportunities for professional development.

7. Practice and Prepare

Practice your answers to common interview questions and prepare to discuss your qualifications and experience. Seek feedback from a career counselor or trusted friend to refine your presentation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Miter Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.