Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mixing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mixing Machine Operator so you can tailor your answers to impress potential employers.

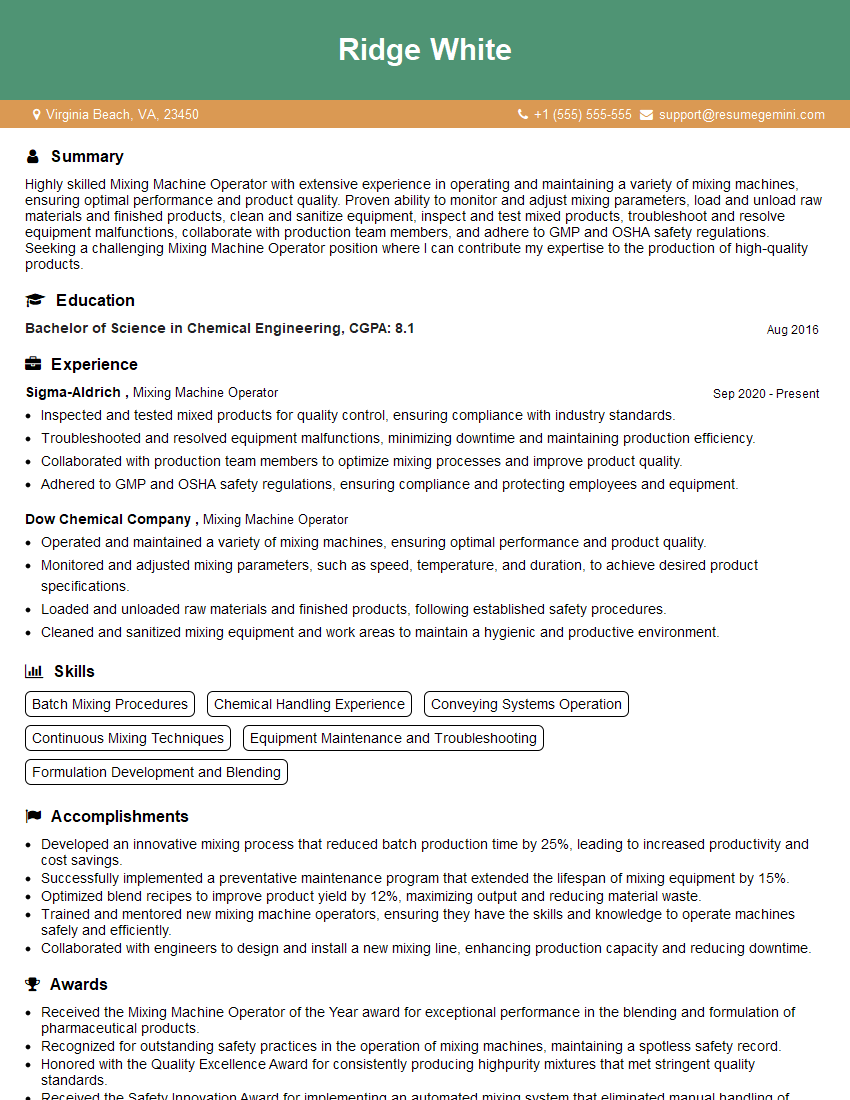

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixing Machine Operator

1. How do you ensure the accuracy of the mixing process?

To ensure the accuracy of the mixing process, I follow several key steps:

- Proper Equipment Calibration: I calibrate all mixing equipment regularly to maintain their accuracy and precision.

- Ingredient Measurement: I meticulously measure and weigh each ingredient according to the specified recipe, using calibrated measuring devices.

- Mixing Time and Speed: I adhere to the prescribed mixing time and speed parameters to achieve the desired consistency and uniformity.

- Quality Control Checks: I perform regular quality control checks throughout the mixing process, including visual inspections and sampling for testing.

- Recordkeeping: I maintain accurate records of all mixing processes, including ingredient quantities, mixing parameters, and any deviations observed.

2. What troubleshooting steps do you take when a mixing issue arises?

Identifying the Issue:

- Inspect the machine for any visible defects or leaks.

- Check ingredient compatibility and ensure they are not reacting adversely.

- Review the mixing parameters and confirm they align with the recipe.

Resolving the Issue:

- Calibrate or repair equipment as necessary.

- Adjust mixing parameters (e.g., time, speed, temperature).

- Modify ingredient ratios or sources if compatible alternatives are available.

- Consult with colleagues or supervisors for additional insights.

3. How do you maintain a clean and sanitary work area around the mixing machine?

Maintaining a clean and sanitary work area is crucial for product quality and safety:

- Regular Cleaning: I thoroughly clean the mixing machine and surrounding area before and after each use, following established cleaning protocols.

- Disinfection: I use approved sanitizing agents to disinfect all surfaces that come into contact with ingredients or finished products.

- Waste Disposal: I promptly dispose of waste materials and empty containers to prevent contamination.

- Personal Hygiene: I practice good personal hygiene, including wearing appropriate protective gear and washing my hands regularly.

- Environmental Control: I monitor and maintain proper ventilation, temperature, and humidity levels to minimize the risk of contamination.

4. What safety precautions do you observe when operating a mixing machine?

Safety is paramount when operating mixing machines:

- Proper Training: I have received comprehensive training on the safe operation of the mixing machine.

- Protective Gear: I wear appropriate safety gear, such as gloves, safety glasses, and ear protection.

- Machine Inspection: I inspect the machine regularly for any potential hazards or defects.

- Lockout/Tagout: I ensure that all power sources are locked out and tagged before performing any maintenance or repairs.

- Careful Operation: I pay attention to the machine’s operation and avoid distractions.

- Emergency Procedures: I am familiar with emergency procedures and know how to respond to any potential incidents.

5. Describe the different types of mixing machines and their applications.

There are various types of mixing machines, each suited to specific applications:

- Ribbon Blender: Blends dry powders and granules, ideal for uniform distribution.

- Horizontal Kneader: Used for dough mixing and kneading in the food industry.

- Vertical Screw Mixer: Provides efficient mixing of viscous liquids and solids.

- Planetary Mixer: Features a rotating beater that moves around a fixed bowl, suitable for a wide range of mixing tasks.

- Turbine Agitator: Used for mixing liquids in large tanks or vessels.

- Colloid Mill: Homogenizes and grinds materials to create fine emulsions or dispersions.

6. Explain the importance of preventative maintenance for mixing machines.

Preventative maintenance is crucial for:

- Equipment Longevity: Regular maintenance extends the lifespan of the machine and reduces the risk of breakdowns.

- Safety: Identifying and addressing potential hazards ensures the safe operation of the machine.

- Product Quality: Properly maintained machines produce consistent and high-quality products.

- Efficiency: Well-maintained machines operate more efficiently, reducing energy consumption and downtime.

- Cost Savings: Preventative maintenance can identify and resolve minor issues before they escalate into costly repairs.

7. Describe the role of mixing parameters in the mixing process.

Mixing parameters play a vital role in achieving the desired mixing results:

- Mixing Time: Determines the duration of the mixing operation and influences the homogeneity and uniformity of the mixture.

- Mixing Speed: Controls the intensity of the mixing action and impacts the distribution of ingredients.

- Mixing Temperature: Can affect the viscosity, solubility, and chemical reactions of the ingredients.

- Fill Level: The volume of ingredients in the mixing vessel influences the efficiency and effectiveness of the mixing process.

- Mixing Order: The sequence in which ingredients are added can impact the final product characteristics.

8. How do you handle batch-to-batch consistency in mixing operations?

Ensuring batch-to-batch consistency is crucial:

- Standardized Recipes: I strictly follow standardized recipes and procedures to maintain ingredient ratios and mixing parameters.

- Equipment Calibration: I regularly calibrate all equipment to ensure accurate measurements and consistent mixing.

- Quality Assurance: I conduct quality checks throughout the mixing process to monitor product quality and identify any deviations.

- Process Control: I document all mixing parameters, including time, speed, temperature, and fill level, to ensure consistency.

- Continuous Improvement: I actively seek feedback and make adjustments to improve efficiency and maintain consistent product quality.

9. Explain the concept of mixing efficiency and how you optimize it.

Mixing efficiency refers to the ability of the mixing machine to achieve the desired mixing results in a timely and energy-efficient manner:

- Appropriate Mixer Selection: I choose the right type of mixer based on the ingredients and desired mixing outcomes.

- Optimized Mixing Parameters: I determine the optimal mixing time, speed, and other parameters through experimentation and data analysis.

- Proper Machine Maintenance: I ensure the mixer is well-maintained and calibrated to operate at peak efficiency.

- Efficient Ingredient Loading: I optimize the loading sequence and fill level to maximize mixing effectiveness.

- Monitoring and Adjustments: I monitor the mixing process and make necessary adjustments to maintain consistent efficiency.

10. Describe your experience in troubleshooting mixing issues.

Troubleshooting mixing issues requires a systematic approach:

- Problem Identification: I first identify the specific mixing issue and its potential causes.

- Root Cause Analysis: I conduct a thorough investigation to determine the underlying factors contributing to the issue.

- Implementation of Solutions: I develop and implement appropriate solutions based on my analysis, considering technical feasibility and cost-effectiveness.

- Testing and Verification: I test the implemented solutions and verify their effectiveness in resolving the mixing issue.

- Preventive Measures: I document the issue and its resolution to prevent similar occurrences in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mixing Machine Operators are responsible for overseeing the operation of mixing machines that blend various ingredients to create a uniform mixture. Their primary tasks involve:

1. Operating Mixing Machines

Loading ingredients into the mixing machine, ensuring accurate weighing and measuring.

- Setting machine parameters, such as mixing speed and duration, according to product specifications.

- Monitoring the mixing process, making adjustments as needed to achieve optimal results.

2. Quality Assurance

Inspecting raw materials and finished products to ensure adherence to specifications.

- Conducting tests to verify the quality of the mixture, such as viscosity and density.

- Maintaining accurate records of mixing parameters and quality control data.

3. Equipment Maintenance

Performing basic maintenance and cleaning of mixing machines and related equipment.

- Troubleshooting and resolving minor technical issues.

- Reporting any major equipment malfunctions or maintenance requirements.

4. Safety Compliance

Adhering to all safety protocols and regulations related to mixing operations.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area.

Interview Tips

To ace your interview for a Mixing Machine Operator role, it’s essential to highlight your technical skills, attention to detail, and understanding of industry regulations.

1. Research the Company and Role

Demonstrate your interest and knowledge by researching the company’s products or services and the specific responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles related to mixing and processing.

2. Emphasize Your Technical Expertise

Showcase your proficiency in operating mixing machines, understanding the principles of mixing, and troubleshooting common issues.

- Provide examples of successful projects where you applied your technical skills.

- Discuss your knowledge of different mixing techniques and equipment.

3. Highlight Your Attention to Detail

Emphasize your ability to follow instructions precisely, maintain accurate records, and ensure the consistent quality of products.

- Share examples of your meticulousness and ability to work with precision.

- Explain how you have maintained high standards of quality control in previous roles.

4. Demonstrate Your Safety Awareness

Convey your commitment to safety by highlighting your knowledge of industry regulations and your experience in maintaining a safe work environment.

- Discuss your understanding of the Material Safety Data Sheets (MSDSs) of chemicals used in mixing.

- Describe your experience with proper handling and storage procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mixing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.