Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Model Engine Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

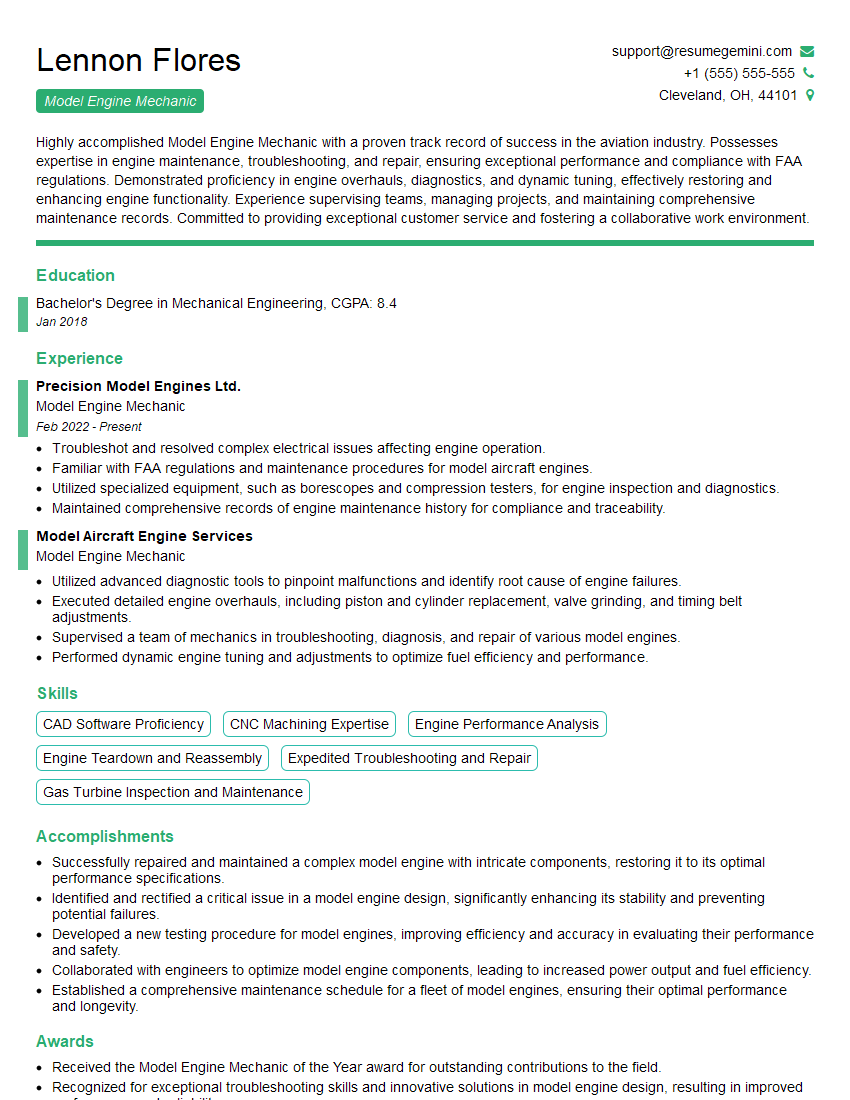

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Model Engine Mechanic

1. Explain the process of assembling a model engine?

The process of assembling a model engine typically involves the following steps:

- Preparation: Gather all necessary tools, materials, and parts. Inspect parts for any damage or defects.

- Engine Block: Assemble the engine block by joining the crankcase, cylinder head, camshaft, and other components.

- Pistons and Connecting Rods: Install the pistons into the cylinders and attach the connecting rods to the crankshaft.

- Camshaft and Timing: Time the camshaft correctly and secure it in place. Adjust valve clearances and timing.

- Intake and Exhaust: Install the intake and exhaust manifolds, carburettor or fuel injector, and spark plug.

- Cooling System: If applicable, assemble and connect the cooling system, including radiator, water pump, and hoses.

- Lubrication System: Install the oil pump, oil filter, and any necessary oil lines.

- Electrical System: Wire and connect the ignition system, battery, starter motor, and other electrical components.

- Testing and Adjustments: Perform initial testing, check for leaks, adjust timing and fuel mixture as needed.

2. What are the different types of fuels used in model engines?

- Glow Fuel: A mixture of methanol, nitromethane, oil, and additives. Requires a glow plug for ignition.

- Gasoline: Used in spark ignition engines. Requires a carburettor for fuel delivery and a spark plug for ignition.

- Diesel Fuel: Used in compression ignition engines. Requires a diesel injector for fuel delivery.

- Electric Power: Electric motors powered by batteries or fuel cells.

3. How do you troubleshoot a faulty model engine?

Troubleshooting a faulty model engine involves a systematic approach:

- Identify Symptoms: Observe the engine’s behavior and identify symptoms such as no start, rough running, or lack of power.

- Check Basics: Verify fuel supply, spark, and compression. Ensure proper assembly and timing.

- Inspect Components: Examine the engine for loose or damaged parts, clogged carburettor, faulty spark plug, or other potential issues.

- Test and Replace: Perform tests to isolate the problem, such as spark testing or compression testing. Replace faulty components as necessary.

- Adjust Settings: Check and adjust engine settings, such as fuel mixture, timing, or valve clearances, according to specifications.

4. What are the common materials used in the construction of model engines?

- Aluminium: Lightweight and strong, used for crankcases, cylinder heads, and other components.

- Steel: Durable and used for crankshafts, connecting rods, and gears.

- Brass: Corrosion-resistant and used for bearings, fittings, and fuel lines.

- Plastic: Lightweight and used for manifolds, carburetor bodies, and other non-critical parts.

- Composite Materials: Used for high-performance components, such as pistons and propellers.

5. How do you calculate the displacement of a model engine?

The displacement of a model engine is the volume of the cylinder swept by the piston. It is calculated using the following formula:

- Displacement = (Bore^2 * Stroke) / 4 * Number of Cylinders

- Bore: Diameter of the cylinder.

- Stroke: Distance the piston moves from top dead centre to bottom dead centre.

- Number of Cylinders: Number of cylinders in the engine.

6. What are the factors that affect the performance of a model engine?

- Engine Design: Displacement, compression ratio, intake and exhaust systems, valve timing.

- Fuel Quality: Type of fuel, octane rating, fuel mixture ratio.

- Propeller Size: Diameter and pitch of the propeller.

- Environmental Conditions: Temperature, humidity, altitude.

- Maintenance: Regular tuning, cleaning, and replacement of worn parts.

7. How do you ensure that a model engine is balanced properly?

Balancing a model engine is crucial for smooth operation and reduced vibrations:

- Dynamic Balancing: Use a balancing machine to measure and adjust the weight distribution of the rotating assembly (crankshaft, connecting rods, pistons).

- Static Balancing: Place the crankshaft on two V-blocks and add weights as needed to balance the assembly.

- Propeller Balancing: Use a propeller balancer to check and adjust the balance of the propeller.

8. What are the safety precautions that must be taken when working with model engines?

- Wear Protective Gear: Safety glasses, gloves, and hearing protection.

- Operate in a Well-Ventilated Area: Exhaust fumes can be harmful.

- Handle Fuel Safely: Use proper containers and avoid spills.

- Keep Away from Heat Sources: Model engines can generate heat and spark.

- Secure the Engine: Mount the engine securely to prevent it from becoming loose during operation.

9. How do you stay updated with the latest advancements in model engine technology?

- Attend Industry Events: Trade shows and conferences offer opportunities to learn about new products and innovations.

- Read Technical Journals: Subscribe to model engine magazines and industry publications.

- Online Forums and Communities: Engage with other model engine enthusiasts and experts to share knowledge and experience.

- Manufacturers’ Websites: Visit websites of reputable model engine manufacturers for updates and technical information.

10. How do you handle customer complaints or requests for technical support?

Handling customer complaints and requests for technical support requires:

- Active Listening: Listen attentively to understand the customer’s concerns and needs.

- Troubleshooting: Ask relevant questions to identify the root cause of the issue.

- Technical Expertise: Provide accurate and detailed information to resolve the customer’s problem.

- Courteous and Professional: Maintain a positive and helpful demeanor throughout the interaction.

- Follow-Up: Check in with the customer to ensure their issue has been resolved satisfactorily.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Model Engine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Model Engine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Model Engine Mechanics are responsible for a variety of tasks, including:

1. Troubleshooting and repairing model engines

This may involve diagnosing the problem, repairing or replacing parts, and testing the engine to ensure proper operation.

- Diagnosing the problem by listening to the engine, checking the spark plug, and performing other tests

- Repairing or replacing parts, such as the carburetor, fuel lines, and spark plug

- Testing the engine to ensure proper operation

2. Building and assembling model engines

This involves following blueprints and instructions to assemble the engine correctly.

- Following blueprints and instructions to assemble the engine correctly

- Using hand tools and power tools to assemble the engine

- Testing the engine to ensure proper operation

3. Maintaining and cleaning model engines

This involves cleaning the engine, replacing filters, and lubricating moving parts.

- Cleaning the engine with a brush and solvent

- Replacing filters, such as the air filter and fuel filter

- Lubricating moving parts with oil or grease

4. Testing and tuning model engines

This involves running the engine on a dyno to measure performance and make adjustments to improve it.

- Running the engine on a dyno to measure performance

- Making adjustments to the engine, such as adjusting the carburetor and timing

- Testing the engine again to verify the improvements

Interview Tips

To ace an interview for a Model Engine Mechanic position, it is important to be prepared and to have a good understanding of the job responsibilities. Here are some tips to help you succeed:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get a sense of the company culture and employee satisfaction.

- Review the job description carefully and identify the key skills and experience that the employer is looking for.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method to answer questions about your experience.

- Be specific and provide examples to support your answers.

- Practice answering questions with a friend or family member.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also arrive on time for your interview, as this shows that you are respectful of the interviewer’s time.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the position and the company. Be positive and upbeat during your interview, and show the interviewer that you are genuinely interested in the opportunity.

5. Ask questions

Asking questions at the end of the interview shows that you are engaged and interested in the position. It is also a good way to learn more about the company and the role.

Next Step:

Now that you’re armed with the knowledge of Model Engine Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Model Engine Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini