Feeling lost in a sea of interview questions? Landed that dream interview for Molasses and Caramel Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Molasses and Caramel Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

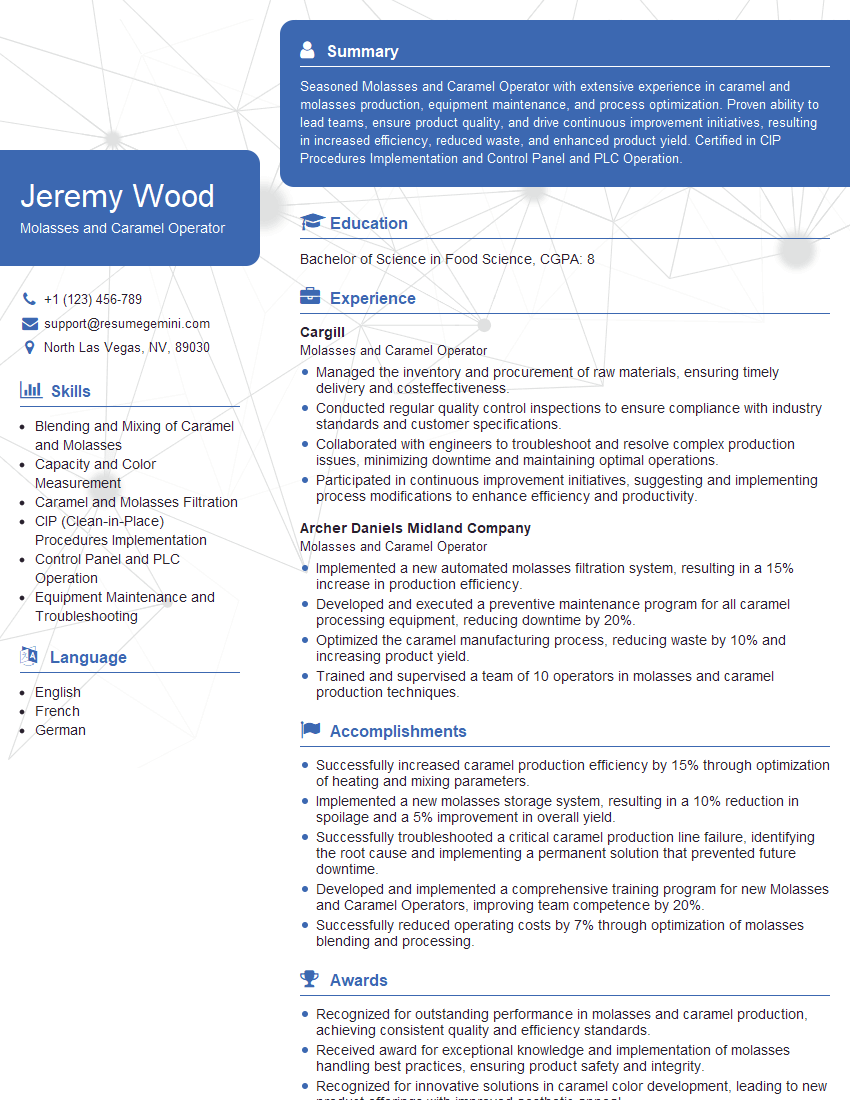

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molasses and Caramel Operator

1. Explain the process of molasses and caramel production?

The process of molasses and caramel production involves several steps:

- Sugarcane Preparation: The process begins with the preparation of sugarcane by removing leaves and cutting it into smaller pieces.

- Crushing and Extraction: The sugarcane is crushed to extract juice using a milling machine. The juice is then filtered to remove impurities.

- Boiling and Clarification: The sugarcane juice is boiled to concentrate it and remove impurities. This process is known as clarification.

- Crystallization: The concentrated juice is cooled to allow sugar crystals to form. These crystals are then separated from the liquid using a centrifuge.

- Molasses Production: The remaining liquid after crystallization is molasses. It is a thick, dark, and sweet liquid that contains various minerals and nutrients.

- Caramel Production: Molasses can be further heated to produce caramel. Heating molasses causes it to darken and develop a characteristic flavor and aroma.

2. What are the key quality parameters for molasses and caramel?

- Molasses:

- Brix (sugar content)

- Viscosity

- Color

- Flavor

- Purity

- Caramel:

- Brix (sugar content)

- Color

- Flavor

- Aroma

- Viscosity

3. Describe the different types of molasses?

There are several types of molasses, classified based on their sugar content and production process:

- Light Molasses: Light in color with a mild flavor and relatively high sugar content.

- Dark Molasses: Darker in color with a stronger flavor and lower sugar content.

- Blackstrap Molasses: The darkest and thickest type, with a robust flavor and the lowest sugar content.

- Industrial Molasses: Used as an additive in animal feed and other industrial applications.

- Sulfurated Molasses: A specific type of molasses treated with sulfur dioxide to prevent crystallization.

4. What are the applications of molasses and caramel in the food industry?

- Molasses:

- Sweetener in baked goods, sauces, and marinades

- Flavor enhancer in dishes like gingerbread and barbecue sauce

- Additive in animal feed and pet food

- Caramel:

- Topping for desserts and beverages

- Flavoring in candies, baked goods, and ice cream

- Coloring agent in food products

5. Discuss the safety precautions that must be considered when working with molasses and caramel?

- Wear appropriate protective gear (gloves, apron, goggles)

- Handle hot molasses and caramel with care to avoid burns

- Ensure proper ventilation to prevent exposure to fumes

- Clean equipment and work surfaces thoroughly after use

- Follow proper storage procedures to maintain product quality

6. Describe the equipment used in the production of molasses and caramel?

- Sugarcane crushers

- Extraction mills

- Clarifiers

- Crystallizers

- Centrifuges

- Boilers

- Caramelizers

7. Explain the role of temperature and pH in molasses and caramel production?

- Temperature:

- Critical for controlling crystallization and caramelization

- High temperatures promote caramelization

- pH:

- Affects the solubility of sugar

- Adjusting pH can influence the crystallization process

8. Discuss the challenges and opportunities in the molasses and caramel industry?

- Challenges:

- Fluctuations in sugarcane production

- Competition from alternative sweeteners

- Changing consumer preferences

- Opportunities:

- Growing demand for natural and healthy sweeteners

- Expansion into new markets and applications

- Development of innovative products

9. What is your understanding of the regulatory requirements for molasses and caramel production?

Regulatory requirements vary depending on the region. However, common regulations include:

- Food safety regulations

- Labeling and packaging standards

- Environmental regulations (wastewater disposal, air emissions)

10. How do you ensure compliance with safety and quality standards in molasses and caramel production?

- Implement and follow established safety protocols

- Regularly monitor product quality through testing and inspections

- Maintain accurate records and documentation

- Train employees on safety and quality procedures

- Conduct regular audits and reviews to identify areas for improvement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molasses and Caramel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molasses and Caramel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Molasses and Caramel Operator is responsible for the production and quality control of molasses and caramel in a manufacturing setting. The role involves operating and maintaining equipment, ensuring compliance with safety and regulatory standards, and maintaining a clean and organized work environment.

1. Operation of Production Equipment

Operate and maintain equipment used in the production of molasses and caramel, including mixers, cookers, and cooling systems.

- Monitor and adjust equipment settings to ensure optimal production conditions.

- Troubleshoot and resolve equipment malfunctions.

2. Quality Control and Testing

Test and ensure the quality of molasses and caramel products.

- Conduct regular tests to measure product viscosity, color, and flavor.

- Identify and correct any quality deviations.

3. Sanitation and Safety

Maintain a clean and sanitary work environment.

- Follow established safety protocols and wear appropriate protective gear.

- Clean and sanitize equipment and work surfaces.

4. Record Keeping and Documentation

Maintain accurate records of production processes and quality control measures.

- Document equipment settings, test results, and any deviations from standard procedures.

- Prepare reports and provide data to management.

Interview Tips

To ace the interview for a Molasses and Caramel Operator position, it is essential to prepare effectively and showcase your skills and experience.

1. Research the Company and Industry

Gather information about the company, its products, and the molasses and caramel industry. This will help you understand the company’s operations and the role of the Molasses and Caramel Operator within the organization.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your experience, skills, and knowledge of the industry. Tailoring your answers to the specific requirements of the role will demonstrate your understanding of the position.

- Describe your previous experience in molasses or caramel production.

- How do you ensure compliance with safety and quality standards?

3. Highlight Your Technical Skills

Emphasize your technical skills in operating and maintaining production equipment. Describe your experience with mixers, cookers, and other relevant equipment.

- Describe a situation where you resolved a technical issue with production equipment.

- Explain your understanding of the principles of molasses and caramel production.

4. Showcase Your Quality Control Experience

Highlight your experience in quality control and testing. Explain your understanding of the testing methods used to assess the quality of molasses and caramel.

- Describe your experience in conducting tests to measure viscosity, color, and flavor.

- Explain how you identify and correct quality deviations.

5. Be Prepared to Discuss Your Safety Practices

Discuss your adherence to safety protocols and your experience in maintaining a clean and sanitary work environment. Highlight your understanding of the importance of following safety guidelines.

- Explain your experience in wearing appropriate protective gear.

- Provide examples of your proactive measures to prevent accidents or injuries.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molasses and Caramel Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!