Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold and Die Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

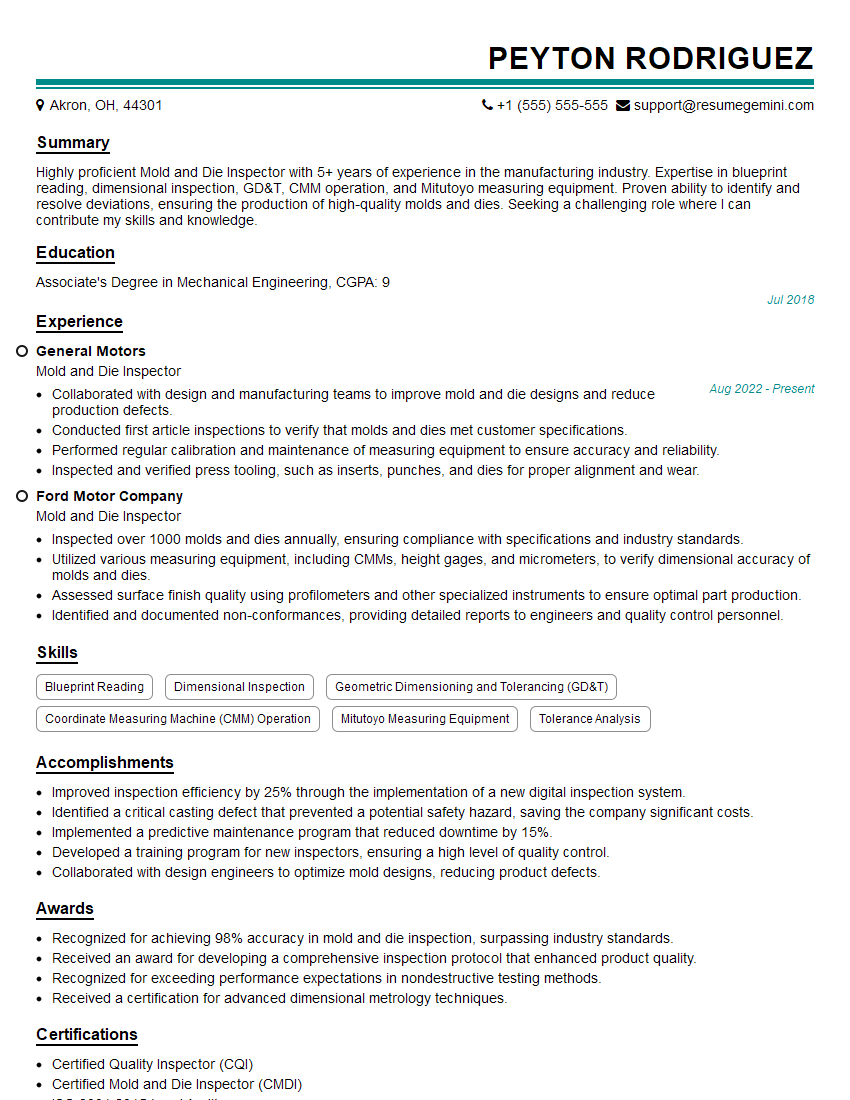

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold and Die Inspector

1. Explain the process of inspecting a mold for dimensional accuracy?

The process of inspecting a mold for dimensional accuracy involves several key steps:

- Preparation: Review the mold design specifications and establish the required tolerances.

- Measurement: Use precision measuring instruments such as CMMs, calipers, and micrometers to measure critical dimensions of the mold, including core and cavity dimensions, parting lines, and overall size.

- Data Analysis: Compare the measured dimensions to the design specifications and calculate any deviations. Identify any areas that fall outside the acceptable tolerance range.

- Reporting: Document the inspection results in a detailed report, including any non-conformances or areas requiring corrective action.

2. How do you ensure the quality of the molds and dies you inspect?

Quality Control Procedures:

- Visual Inspection: Examine mold surfaces for scratches, burrs, or any physical defects.

- Dimensional Inspection: Utilize precision measuring equipment to verify dimensions against specifications.

- Functional Testing: Simulate the molding process to assess mold performance and identify any potential issues.

Documentation and Traceability:

- Inspection Records: Maintain detailed records of all inspections, including measurements, observations, and corrective actions.

- Traceability: Ensure that each mold or die can be traced back to its inspection records for quality assurance purposes.

3. What are the most common defects you encounter during mold and die inspections?

- Dimensional Errors: Incorrect dimensions, such as misaligned core and cavity sizes or deviations from design specifications.

- Surface Defects: Scratches, pits, or burrs on mold surfaces that can affect part quality.

- Parting Line Flash: Excess material that leaks from the parting line during molding, causing imperfections on the molded parts.

- Warpage or Distortion: Deviations in the shape or flatness of the mold or die due to uneven heat distribution or improper heat treatment.

- Gate and Runner Issues: Problems with gate design or runner sizes that affect material flow and part quality.

4. Describe the types of measuring instruments you use for mold and die inspections?

- Coordinate Measuring Machines (CMMs): High-precision machines that measure three-dimensional coordinates to verify mold dimensions.

- Calipers: Handheld instruments for measuring external and internal dimensions, such as cavity depths or flange thicknesses.

- Micrometers: Precision measuring tools for highly accurate measurements of small dimensions, such as gate sizes or tolerances.

- Optical Comparators: Project images of the mold or die onto a screen for visual inspection and comparison to reference profiles.

- 3D Scanners: Capture detailed surface data of molds or dies for digital inspection and analysis.

5. How do you handle non-conformances identified during mold and die inspections?

- Corrective Action Plan: Determine the cause of the non-conformance and develop a plan to address it.

- Communication: Notify the appropriate stakeholders, such as design engineers, toolmakers, or quality managers, about the issue.

- Repair or Replacement: If necessary, arrange for repairs or replacement of the defective mold or die.

- Documentation: Record all actions taken and maintain a history of non-conformances for future reference.

6. What are the safety protocols you follow when working with molds and dies?

- Personal Protective Equipment (PPE): Wear appropriate safety gear, such as gloves, safety glasses, and proper footwear.

- Machine Guarding: Ensure that all machinery is properly guarded to prevent accidents.

- Material Handling: Exercise caution when handling heavy molds or dies and follow safe lifting techniques.

- Electrical Safety: Always inspect electrical connections and ensure proper grounding to prevent electrical hazards.

- Hazardous Materials: Be aware of any hazardous materials used in the molding or die-making process and follow proper handling procedures.

7. How do you stay up-to-date with the latest industry standards and best practices for mold and die inspection?

- Professional Development: Attend industry conferences, workshops, or training programs to enhance knowledge.

- Trade Publications: Read industry journals and publications to stay informed about new techniques and technologies.

- Networking: Connect with colleagues and professionals in the field to share knowledge and discuss industry trends.

- Online Resources: Utilize online forums and websites to access technical information and best practices.

- Company Training: Participate in company-sponsored training programs to ensure alignment with internal standards and procedures.

8. How do you prioritize your workload and manage your time effectively?

- Task Prioritization: Identify critical tasks and allocate time accordingly, focusing on high-priority inspections.

- Scheduling: Plan daily and weekly schedules to ensure efficient use of time and avoid bottlenecks.

- Delegation: Delegate tasks to subordinates or colleagues when appropriate to optimize workflow.

- Time Management Tools: Utilize calendars, task lists, and other tools to track progress and stay organized.

- Continuous Improvement: Regularly evaluate your workflow and identify areas for improvement to increase productivity.

9. How do you handle tight deadlines and pressure while maintaining accuracy in your inspections?

- Effective Planning: Anticipate workload and plan ahead to avoid last-minute rushes.

- Prioritization: Focus on completing critical tasks within the deadline while maintaining quality standards.

- Time Management: Optimize time by using efficient inspection techniques and minimizing distractions.

- Communication: Keep stakeholders informed about any potential delays or challenges to manage expectations.

- Stress Management: Utilize stress-reducing techniques to maintain composure and accuracy under pressure.

10. How do you collaborate with other departments, such as design and production, to ensure successful mold and die inspections?

- Regular Communication: Maintain open communication channels with design and production teams to exchange information and address issues promptly.

- Problem-Solving: Collaborate to identify and resolve any design or manufacturing problems that may impact mold or die performance.

- Feedback Provision: Provide feedback to design engineers on moldability and manufacturability issues to enhance future designs.

- Cross-Functional Team Approach: Participate in cross-functional teams to share expertise and improve overall product quality.

- Process Optimization: Work with production teams to optimize molding or die-making processes based on inspection findings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold and Die Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold and Die Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold and die inspectors are responsible for ensuring that molds and dies meet the required specifications. They inspect the molds and dies for defects, and they also measure and test the molds and dies to ensure that they are within tolerance.

1. Inspect molds and dies for defects

Mold and die inspectors use a variety of tools and techniques to inspect molds and dies for defects. They may use visual inspection, dimensional measurement, or non-destructive testing to identify defects.

- Visual inspection involves looking for defects on the surface of the mold or die.

- Dimensional measurement involves measuring the mold or die to ensure that it meets the required specifications.

- Non-destructive testing involves using special equipment to test the mold or die without damaging it.

2. Measure and test molds and dies

Mold and die inspectors also measure and test molds and dies to ensure that they are within tolerance. They may use calipers, micrometers, or other measuring tools to measure the mold or die.

- Calipers are used to measure the inside and outside dimensions of the mold or die.

- Micrometers are used to measure the thickness of the mold or die.

- Other measuring tools, such as rulers or tapes, may also be used to measure the mold or die.

3. Report defects and recommend corrective action

Mold and die inspectors report any defects that they find to the appropriate supervisor. They may also recommend corrective action to prevent the defects from recurring.

- The inspector may recommend that the mold or die be repaired or replaced.

- The inspector may also recommend that the manufacturing process be changed to prevent the defects from occurring.

4. Maintain records

Mold and die inspectors maintain records of their inspections and tests. These records may be used to track the performance of the molds and dies, and they may also be used to identify trends in the manufacturing process.

- The inspector may keep a log of the inspections and tests that they perform.

- The inspector may also keep a record of the defects that they find.

Interview Tips

Here are some tips to help you ace your interview for a mold and die inspector position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to prepare for the specific questions that you may be asked during the interview.

- Visit the company’s website to learn more about their products and services.

- Read articles about the company in trade publications or online.

- Talk to people who work at the company to get their insights on the culture and the work environment.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked during your interview. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with mold and die inspection?

- What are your salary expectations?

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a mold and die inspector. Be prepared to talk about your experience in detail, and be sure to highlight your skills and abilities.

- Describe your experience with different types of molds and dies.

- Explain the different inspection techniques that you are familiar with.

- Discuss your experience with measuring and testing molds and dies.

- Highlight your ability to identify and report defects.

- Emphasize your attention to detail and your commitment to quality.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

- Ask about the opportunities for advancement.

Next Step:

Now that you’re armed with the knowledge of Mold and Die Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold and Die Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini