Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold and Die Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

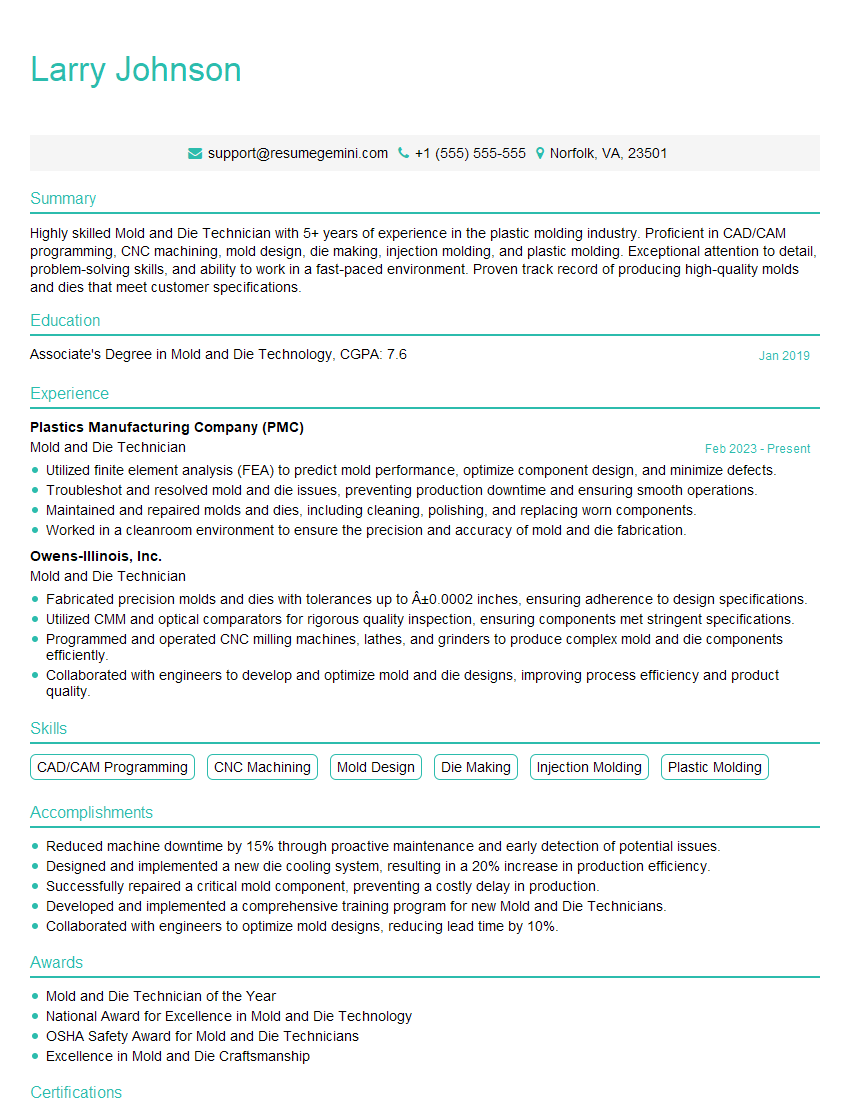

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold and Die Technician

1. How would you calculate the appropriate dimensions of a die for a given part?

- Consider the material shrinkage, the desired part thickness, and any necessary draft angles.

- Use the appropriate formulas and calculations to determine the die dimensions.

- Account for tolerances and safety factors to ensure proper part fit and functionality.

2. Explain the different types of materials used in mold making and their properties.

Metals

- Steel: Durable, wear-resistant, suitable for high-volume production.

- Aluminum: Lightweight, corrosion-resistant, used for prototype and low-volume production.

Non-Metals

- Epoxy: Versatile, inexpensive, used for small or complex parts.

- Silicone: Flexible, heat-resistant, used for injection molding and casting.

3. Describe the steps involved in designing and building a plastic injection mold.

- Design the part and determine the mold requirements.

- Create a 2D/3D model of the mold using CAD software.

- Machine the mold components to precise tolerances.

- Assemble and test the mold to ensure proper functionality.

4. What are the common defects that can occur in plastic injection molding, and how can they be prevented?

- Flash: Excess material seeping between mold plates. Prevented by proper mold design and clamping pressure.

- Sink marks: Depressions on the part surface. Prevented by increasing material temperature or pressure.

- Warping: Distortion of the part. Prevented by controlled cooling and proper mold design.

5. What methods do you use to inspect and maintain molds?

- Visual inspection for wear, chipping, and fractures.

- Dimensional inspection using measuring tools or CMM.

- Regular cleaning, lubrication, and replacement of worn components.

6. Explain the principles of die casting, including the different types of die casting machines.

Principles

- Molten metal is injected under pressure into a mold cavity.

- The metal solidifies and forms the desired part shape.

Machines

- Hot-chamber: Molten metal is stored in a reservoir within the machine.

- Cold-chamber: Molten metal is poured into the machine’s injection chamber before each cycle.

7. What are the safety precautions that must be followed when working with molds and dies?

- Wear appropriate PPE (safety glasses, gloves, etc.).

- Follow lockout/tagout procedures when servicing equipment.

- Be aware of the potential for hot surfaces, moving parts, and pinch points.

8. How do you keep up to date with the latest technologies and best practices in mold and die manufacturing?

- Attend industry conferences and trade shows.

- Read technical journals and online resources.

- Participate in training programs or workshops.

9. What is your experience with designing and building molds for high-tolerance parts?

- Describe your involvement in specific projects involving tight tolerances.

- Explain the methods and techniques used to achieve the required precision.

- Highlight your expertise in tolerancing and quality control.

10. How do you collaborate effectively with other team members, including engineers and production staff?

- Describe your communication and interpersonal skills.

- Provide examples of successful collaborations where you contributed to the overall project success.

- Explain how you manage conflicts and resolve disagreements professionally.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold and Die Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold and Die Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold and Die Technicians are responsible for the maintenance and repair of molds and dies used in various manufacturing processes. They work closely with engineers and designers to ensure that the molds and dies meet the required specifications. Key responsibilities of a Mold and Die Technician include:

1. Maintenance and Repair

Inspect molds and dies for wear and tear, and perform necessary repairs to ensure optimal performance.

- Identify and resolve issues related to mold and die functionality, such as improper alignment, wear, or damage.

- Overhaul and rebuild molds and dies to extend their lifespan.

2. Quality Control

Monitor production processes to ensure that molds and dies are producing parts according to specifications.

- Conduct quality checks on molded or stamped parts to ensure dimensional accuracy and surface finish.

- Analyze and identify non-conforming parts and implement corrective actions.

3. Troubleshooting

Diagnose and resolve technical issues related to molds and dies, reducing downtime and optimizing production efficiency.

- Troubleshoot malfunctions, such as sticking or misalignment, to identify and rectify root causes.

- Develop and implement preventive maintenance plans to minimize equipment downtime.

4. Collaboration

Collaborate with engineers, designers, and production staff to ensure alignment between mold design, manufacturing processes, and quality standards.

- Provide technical support to production teams regarding mold and die operation and maintenance.

- Participate in design reviews and provide input on moldability and manufacturability.

Interview Tips

Preparing for an interview for a Mold and Die Technician position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, industry, and specific job requirements. Research the company’s website, social media pages, and industry news to demonstrate your interest and understanding.

2. Highlight Your Technical Skills

Emphasize your expertise in mold and die maintenance, repair, troubleshooting, and quality control. Quantify your accomplishments to showcase your impact on production efficiency and quality.

3. Prepare for Common Interview Questions

Anticipate questions related to your experience in mold and die troubleshooting, quality control methods, and collaborative work experience. Practice answering these questions concisely and confidently.

4. Showcase Your Problem-Solving Abilities

Mold and Die Technicians often encounter technical challenges. Prepare examples of how you have successfully diagnosed and resolved complex mold or die issues, highlighting your problem-solving skills and attention to detail.

5. Demonstrate Soft Skills

In addition to technical proficiency, emphasize your teamwork, communication, and customer service skills. Highlight situations where you have effectively collaborated with others and provided support to production teams.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold and Die Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.